Source: Sensor Expert Network

Original Author: Dynamic Sensors

In 1959, American physicist Richard Feynman, in his famous speech “There’s Plenty of Room at the Bottom,” proposed the idea of miniaturizing machines to the atomic and molecular scale. However, it wasn’t until the 1980s and 1990s that MEMS technology began to be developed and commercialized.

In 1962, the first silicon micro pressure sensor was invented by pioneers in micro devices, marking the beginning of MEMS technology and the starting point for MEMS micro sensors. Relevant papers from Honeywell Research Center and Bell Labs show that they invented the first silicon diaphragm pressure sensor and strain gauge.

Since then, interest in MEMS sensor technology has surged, and by the late 1960s, many companies had begun producing the first batch of MEMS pressure sensors.

▲Richard Feynman

MEMS technology has developed rapidly and played a crucial role in the popularization of sensors today. Without MEMS technology, the miniaturization, integration, and low power consumption of sensors would be difficult to achieve, and the development of the Internet of Things, smartphones, and automobiles would be severely delayed.

Today, various MEMS sensors and actuators have achieved commercial success, replacing traditional devices and being widely applied. In this article, we will look at these highly successful MEMS sensors and actuators.

1. MEMS Microphones: Instantly Popular in Mobile Devices

In 1961, the famous Bell Labs developed the first electret condenser microphone (ECM), which converts sound into electrical signals by measuring the change in capacitance caused by sound acting on the diaphragm.

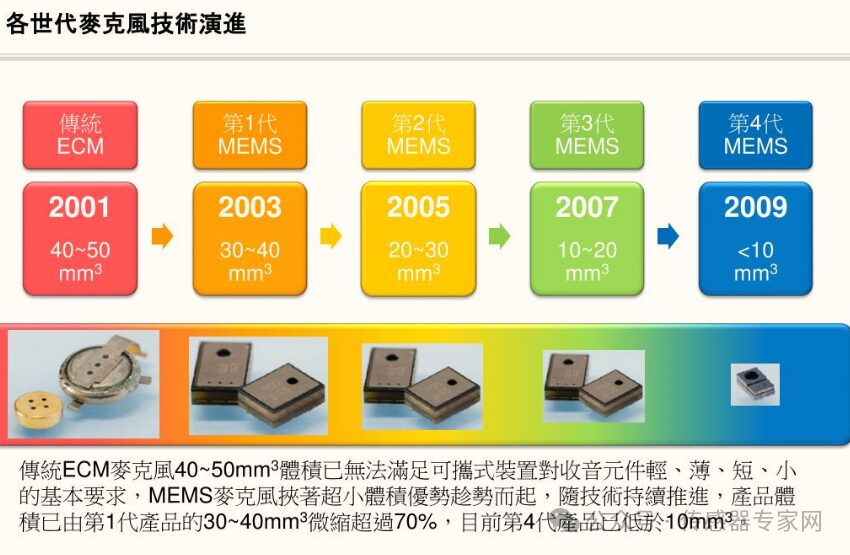

The electret microphone became popular for over 40 years until 2003, when the first commercial MEMS microphone product, the SiSonic microphone from Knowles, hit the market.

At that time, mobile phones were gradually becoming popular and lighter, and traditional electret microphones could not meet the demand for lightweight, thin, and small microphones in mobile devices, leading to the favor of MEMS microphones by mobile phone manufacturers.

▲Source: Digitimes

MEMS microphones have achieved great success in the market, essentially replacing traditional electret microphones, especially in the mobile device market, becoming the mainstream. Each mobile phone typically contains at least three MEMS microphones.

2. MEMS Inertial Sensors: Enabling Inertial Measurement in Mobile Devices

Did you know? The world’s first truly mass-produced MEMS sensor was the accelerometer, invented by the American company ADI in 1991. This sensor operates based on capacitive sensing principles, with its output signal used to measure acceleration or tilt.

This MEMS accelerometer was primarily used in automotive airbags. Previously, traditional sensors for airbags cost around $20 each, while ADI’s MEMS accelerometer was priced at about $5 each, reducing the cost of electronic airbag devices by approximately 75%.

Since then, MEMS inertial sensors have rapidly proliferated, replacing traditional inertial sensors in many fields, creating more application scenarios—such as inertial measurement in mobile devices like smartphones, smartwatches, and TWS earbuds.

MEMS inertial sensors mainly include MEMS gyroscopes, MEMS accelerometers, and MEMS-IMUs (Inertial Measurement Units).

In smartphones, MEMS accelerometers sense motion states by measuring the acceleration of objects in three directions, enabling various functions like screen auto-rotation, pedometers, and game controls.

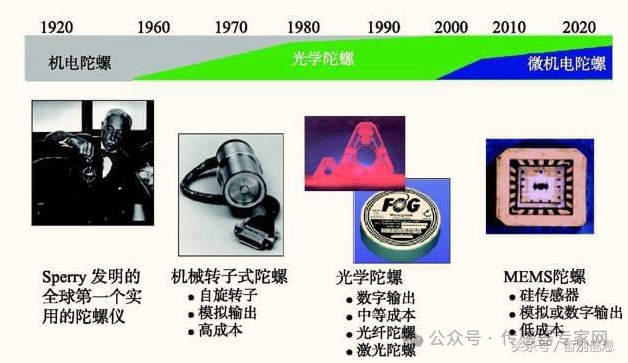

Gyroscopes sense the rotation state of objects by measuring angular velocity. Since Sperry invented the world’s first practical gyroscope nearly a century ago, gyroscope technology has undergone nearly a century of development and is the core of inertial technology.

The first micromechanical gyroscope using MEMS technology appeared in 1989, with a drift rate of 10 degrees/hour. Compared to other gyroscopes, MEMS gyroscopes are cheaper, smaller, more reliable, and easier to mass-produce, making their use in mobile devices feasible.

In smartphones, gyroscopes work together with GPS and geomagnetic sensors to achieve precise positioning and navigation. Additionally, the gravity sensing feature for gaming is more robust and intuitive, significantly enhancing the gaming experience. This feature allows smartphones to continue navigating users even when GPS signals are lost in tunnels, based on the acceleration direction and magnitude sensed by the gyroscope.

Today, with the rise of drones and autonomous driving technology, the application of MEMS gyroscopes is expanding, providing stable and reliable attitude control for these devices.

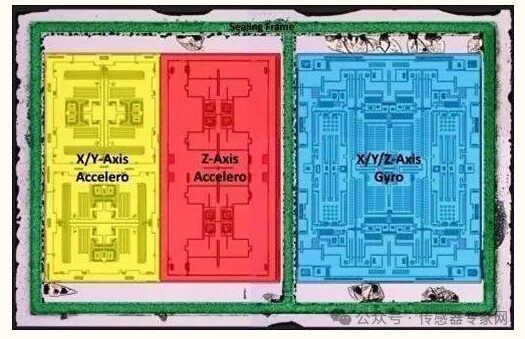

▲Inside InvenSense (TDK) nine-axis inertial measurement unit: gyroscope (right) and accelerometer (left)

MEMS IMUs are now widely applied in consumer electronics, automotive, and industrial automation fields. Currently, with the rapid development and cost reduction of MEMS IMU technology, there is a trend for MEMS IMUs to gradually replace standalone MEMS accelerometers and MEMS gyroscopes.

3. MEMS Pressure Sensors: Driving Miniaturization in Pressure Detection

Pressure is the second largest measurement among various physical quantities. As mentioned earlier, the world’s first MEMS sensor was the silicon micro pressure sensor, invented in 1962 by Honeywell.

Compared to traditional pressure sensors, MEMS pressure sensors have advantages such as no mechanical fatigue or aging, stable output signals, high sensitivity, small size, and suitability for large-scale production (cost advantage). With the development of mobile devices, automobiles, and other fields, MEMS pressure sensors are becoming increasingly popular.

In the healthcare field, pressure sensors are widely used in devices such as blood pressure monitors, ventilators, and monitors, providing doctors with accurate physiological parameter data. Additionally, with the rise of wearable devices, pressure sensors are also used in smart bands and smartwatches to achieve functions like heart rate monitoring and sleep analysis.

▲MEMS Pressure Sensor Applications, Source: Yole

One significant advantage of MEMS pressure sensors is their ability to be made very small, thereby driving their application in miniaturized mobile devices and innovative fields such as healthcare.

4. MEMS DLP Chips: Transforming Traditional Projection Devices, Opening Up the Era of Digital Laser Projection

DLP projection technology is a revolutionary breakthrough in the display field, akin to the enormous impact of CDs in the audio field, as DLP opens a new chapter in video projection display.

The inventor of the Digital Micromirror Device (DMD, or DLP chip), Dr. Larry J. Hornbeck from Texas Instruments, was awarded the 2014 Academy Award for Scientific and Technical Achievement (Oscar) for his outstanding contributions to transforming the century-old film industry into digital film technology, highlighting the significant impact of MEMS DLP chip technology on the imaging industry.

The core component of DLP (Digital Light Processing) chips is the DMD (Digital Micromirror Device), which is an important category of optical MEMS.

In 1977, the development of DLP chips officially started at the Texas Instruments Central Research Laboratory. At that time, Hornbeck first used “deformable mirrors” to control light in a simulated manner, but the applied simulation technology consistently failed to meet expectations. It wasn’t until 1987 that he achieved a breakthrough technically by inventing the DMD (i.e., DLP chip) based on MEMS technology, which changed the situation.

Since then, DLP technology projectors have long occupied over 60% of market share, becoming the mainstream projection technology solution, a situation that has only changed in the past two years.

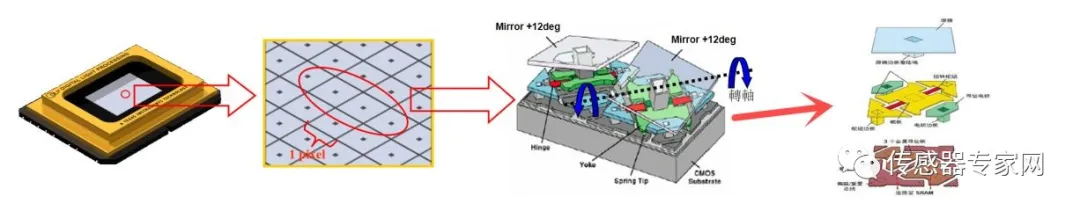

DLP chips use MEMS technology to mass-produce thousands of “mirrors”—micromirrors—on a silicon substrate. The following image shows the packaging structure of a DMA chip.

Inside a DLP chip, there are millions of micromirrors, each of which can independently reverse its motion, flipping in both positive and negative directions, with flipping rates reaching tens of thousands of times per second. The following image illustrates the process of each micromirror flipping and refracting light, where each micromirror can be individually controlled to refract corresponding light, forming different colors and brightness. Each micromirror acts like a pixel in our television.

5. MEMS Inkjet Heads: Dominating the Printing World, Capable of Printing DNA Structures

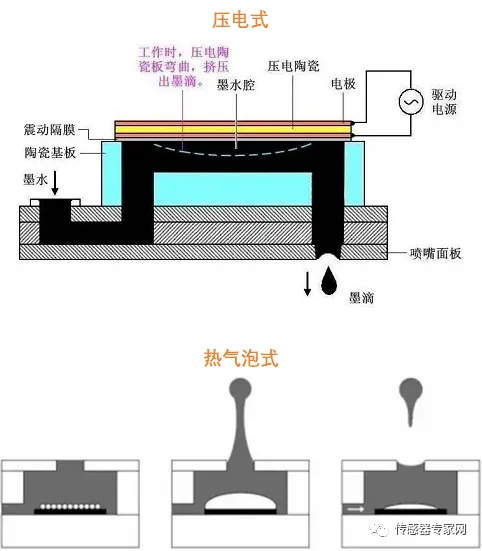

In inkjet printers, MEMS inkjet print heads are the core components responsible for ejecting ink. Some use piezoelectric film vibrations to expel ink, while others utilize the expansion of heating bubbles to push ink out of the chamber.

Interestingly, these two MEMS inkjet technologies have formed two major camps in the printing industry, with Epson and Brother representing the micro-piezo printing technology and HP and Canon utilizing thermal bubble printing technology, competing against each other.

Currently, inkjet printers, laser printers, and dot matrix printers dominate the printing technology landscape.

Furthermore, aside from the MEMS sensors and actuators mentioned above, MEMS filters and MEMS thermoelectric piles are also widely used. At the same time, new MEMS technologies, such as MEMS speakers and MEMS clocks, are showing vigorous development momentum.

END

This reproduced content only represents the author’s views

It does not represent the position of the Institute of Semiconductor, Chinese Academy of Sciences

Editor: March

Editor-in-Chief: Mu Xin

Submission Email: [email protected]

1.The Semiconductor Institute has made progress in research on bionic covering neuron models and learning methods

2.The Semiconductor Institute has made significant progress in inverted structure perovskite solar cells

3.Why is copper used as interconnect metal in chips?

4.What exactly is 7nm in chips?

5.Silicon-based integrated optical quantum chip technology

6.How abnormal is the quantum anomalous Hall effect? It may lead to the next revolution in information technology!