Overview of China’s Automotive Sensor Industry

Basic Concepts and Classifications

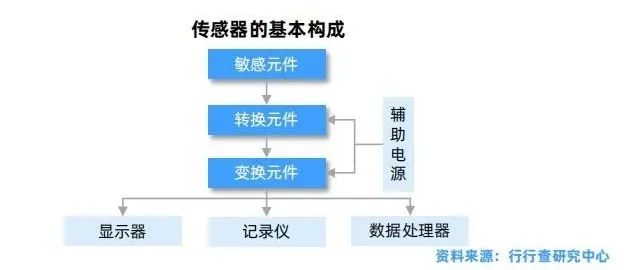

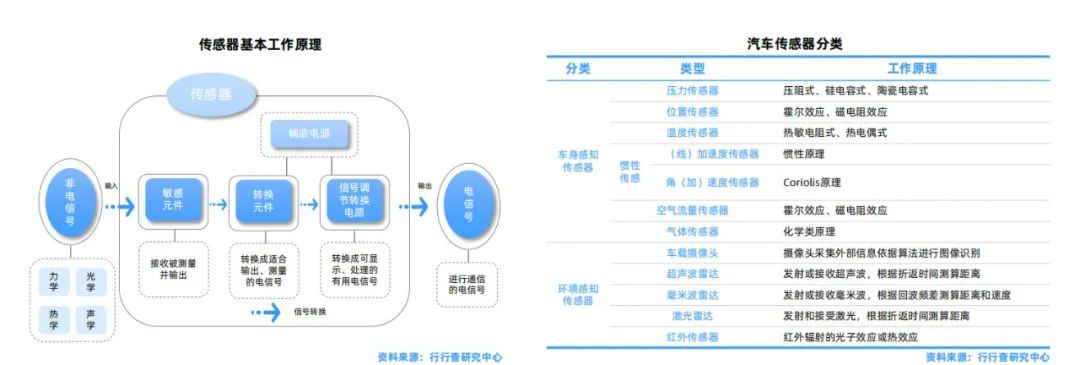

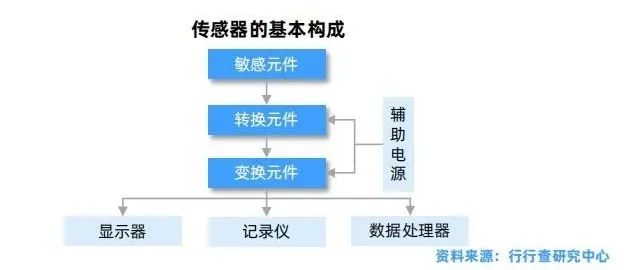

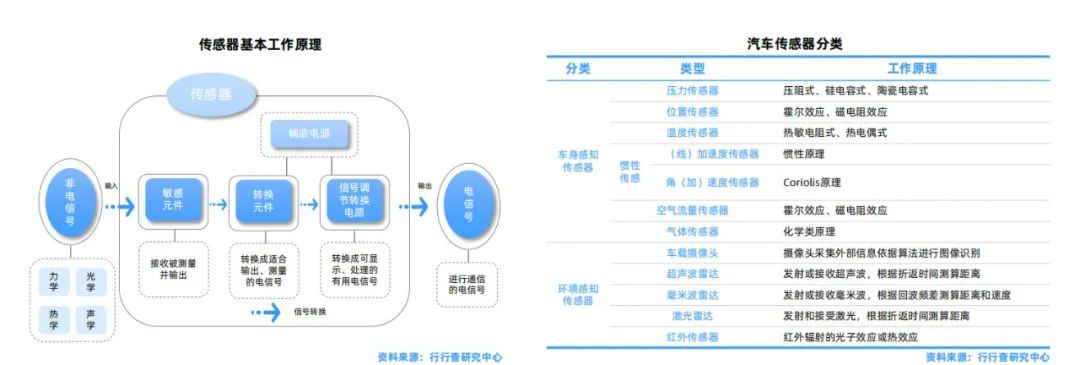

A sensor is a detection device that can sense the information to be measured and convert the sensed information into electrical signals or other desired forms of information output according to certain rules, to meet the requirements for information transmission, processing, storage, display, recording, and control. It usually consists of sensitive elements, conversion elements, signal conditioning and conversion circuits, and other auxiliary components. The sensitive element receives the measured quantity and outputs another quantity that is in a definite relationship with the measured quantity; the conversion element takes the output from the sensitive element as input and converts the sensed non-electrical quantity into an electrical signal output. The electrical signal suitable for output and measurement is converted by the signal conditioning and conversion circuit into useful electrical signals that can be displayed, recorded, processed, and controlled, and finally, the useful electrical signals are transmitted to other devices for communication.

Sensitive Element: The element that directly senses the measured quantity and outputs a certain physical quantity that is in a definite relationship with the measured quantity.

Conversion Element: The core element of the sensor, which takes the output from the sensitive element as input and converts the sensed non-electrical quantity into an electrical signal output. The conversion element itself can be used as an independent sensor, called a component sensor.

Conditioning Circuit: The circuit that converts the electrical signal output from the sensing element into useful electrical signals that are easy to process, control, record, and display.

Auxiliary Power Supply: The conversion elements and conditioning circuits generally also require auxiliary power for operation.

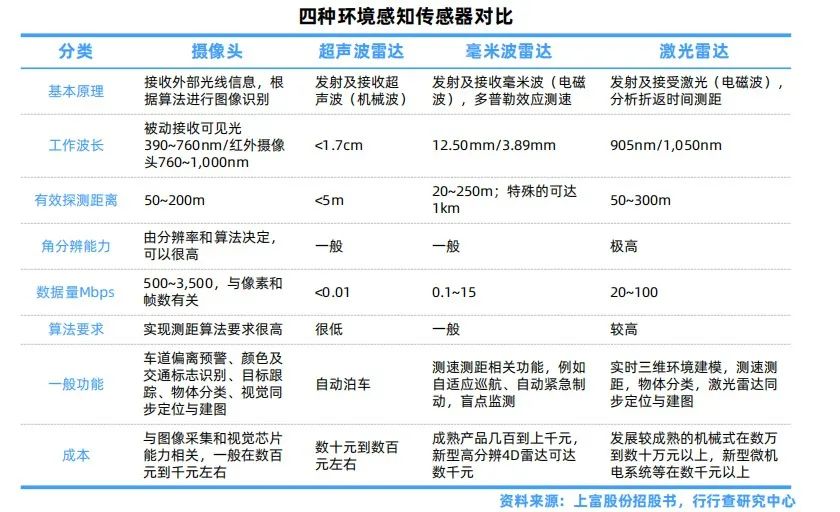

Automotive sensors are devices that convert non-electrical signals into electrical signals and transmit various working condition information to the vehicle. Automotive sensors can be classified based on their usage into body perception sensors and environmental perception sensors. Body perception sensors enhance the information level of the vehicle itself, enabling it to perceive its own conditions; they can be mainly classified into pressure sensors, position sensors, temperature sensors, linear acceleration sensors, angular acceleration sensors, air flow sensors, gas sensors based on the different measured inputs, most of which adopt MEMS solutions from a working principle perspective. Environmental perception sensors enable the vehicle to perceive external environmental conditions, assisting the vehicle’s computer in obtaining environmental information and making planning decisions, thus supporting intelligent driving; environmental perception sensors are mainly classified into onboard cameras, ultrasonic radar, millimeter-wave radar, laser radar, and infrared radar.

Automotive sensors are devices that convert non-electrical signals into electrical signals and transmit various working condition information to the vehicle. Automotive sensors can be classified based on their usage into body perception sensors and environmental perception sensors. Body perception sensors enhance the information level of the vehicle itself, enabling it to perceive its own conditions; they can be mainly classified into pressure sensors, position sensors, temperature sensors, linear acceleration sensors, angular acceleration sensors, air flow sensors, gas sensors based on the different measured inputs, most of which adopt MEMS solutions from a working principle perspective. Environmental perception sensors enable the vehicle to perceive external environmental conditions, assisting the vehicle’s computer in obtaining environmental information and making planning decisions, thus supporting intelligent driving; environmental perception sensors are mainly classified into onboard cameras, ultrasonic radar, millimeter-wave radar, laser radar, and infrared radar.

Development History of China’s Automotive Sensor Industry

Long R&D Cycles and High Product Added Value

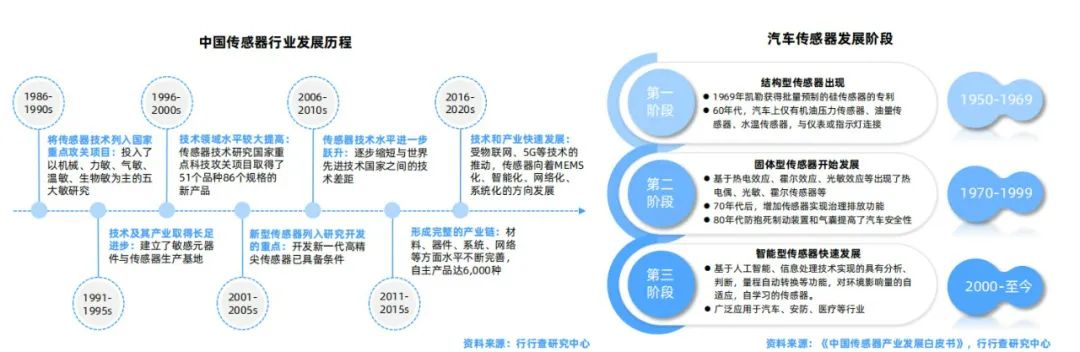

From the perspective of the domestic industry development history, in 1986, the state listed sensor technology as a key national project. By 2000, the sensor technology system and industry were initially established, and the level of domestic sensor technology continued to improve. Since 2016, domestic sensor technology and industry have developed rapidly, driven by technologies such as the Internet of Things, 5G, and artificial intelligence, with sensors continuously developing towards MEMS, intelligence, networking, and systematization.

The development stages of automotive sensors can be classified into structural sensor stage, solid sensor stage, and intelligent sensor stage. Currently, MEMS sensors and intelligent sensors are rapidly developing and are widely used in industries such as automotive, security, and medical. The R&D cycle for automotive sensors is generally long; for example, the average time from design and development to full commercialization of automotive MEMS sensors is 28 years. In the hierarchical structure of autonomous driving, automotive sensors are at the perception layer, with high product added value, making them core hardware for achieving intelligent driving.

Introduction to the Classification of China’s Automotive Sensor Industry

Body Perception Sensors

Body perception sensors are distributed throughout the vehicle and are widely used in power systems (the three electric systems of new energy vehicles), chassis systems, and body systems, achieving the perception of the vehicle’s own information and making decisions and executions, serving as the “nerve endings” of the vehicle. They are currently well-developed, primarily using MEMS sensors.

The power source is one of the main differences between new energy vehicles and traditional fuel vehicles. The electronic and electrical architecture of new energy vehicles mainly uses electromagnetic sensors related to batteries, motors, and electronic controls, while fuel vehicles mainly use sensors that measure pressure, temperature, and gas; the demand for electromagnetic sensors is expected to gradually increase with the penetration rate of new energy vehicles. According to the different physical quantities measured, body perception sensors can be classified into various types such as pressure, position, temperature, acceleration, gas, and flow sensors.

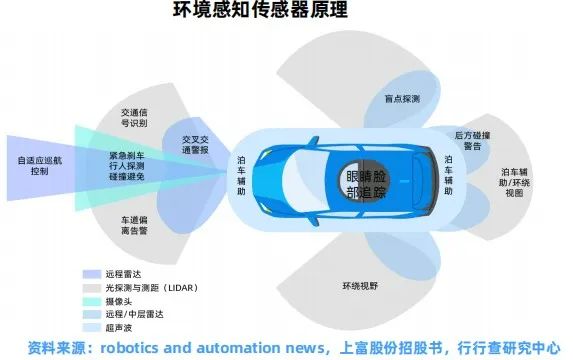

Environmental Perception Sensors

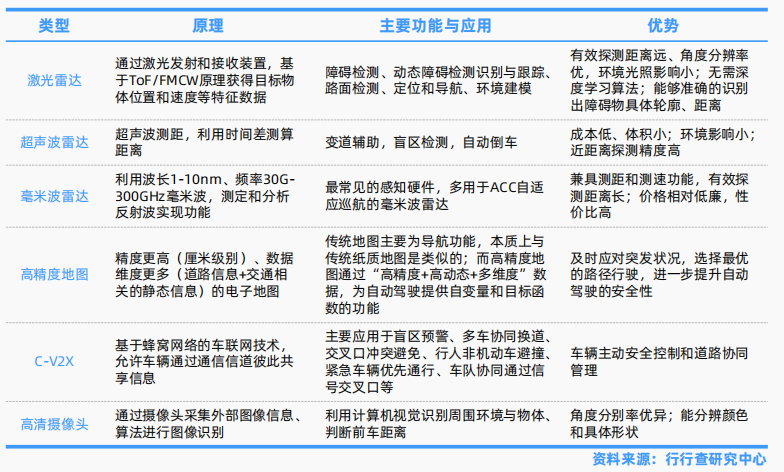

Environmental perception sensors emerged during the evolution of automotive safety technology from passive to active safety. The main function of perception sensors is to detect and identify the surrounding environment of the vehicle, which can be seen as the vehicle’s eyes. Different types of intelligent driving perception systems for vehicles have different applicable scenarios, limitations, advantages, disadvantages, and costs, forming a complementary relationship among each other. Environmental perception sensors capture external information and provide it to the vehicle’s computer system for planning decisions, mainly including laser radar, onboard cameras, millimeter-wave radar, ultrasonic radar, etc.

The intelligent driving perception system of the vehicle is the perception layer of the automotive system, transforming real-world visual, physical, and event information into digital signals, providing basic assurance for the vehicle to understand its surrounding environment and make driving operations, and providing accurate, timely, and sufficient basis for the decision-making layer of advanced driver assistance systems, which is further judged accurately by the execution layer for safe driving.

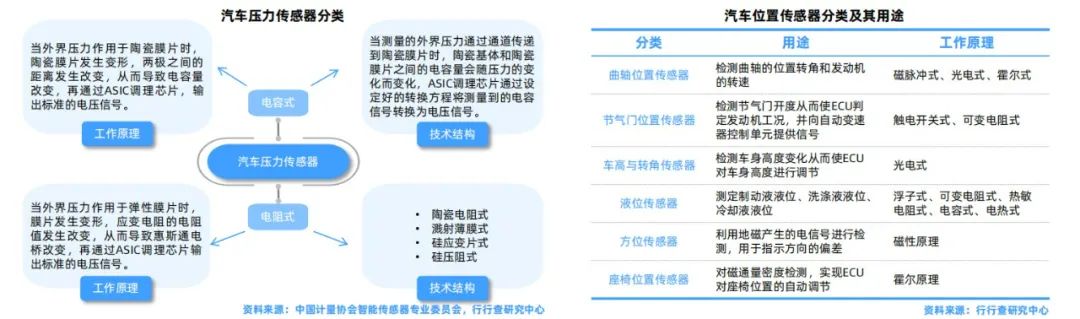

Body Perception:Pressure Sensors

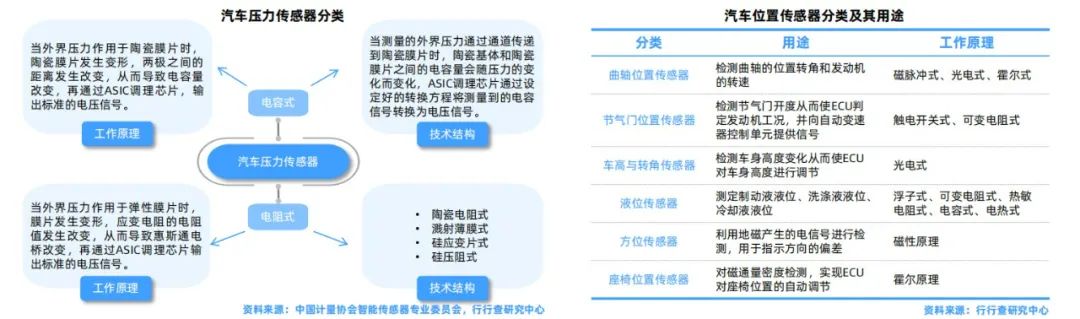

Automotive pressure sensors that convert pressure signals into electrical signals can be mainly classified into capacitive and resistive types. Pressure sensors can sense pressure signals and convert them into usable electrical signals. According to the different mainstream technological principles of pressure-sensitive elements, automotive pressure sensors can be divided into capacitive pressure sensors and resistive pressure sensors, which are typically used in the intake manifold of the engine, to detect atmospheric pressure changes, to measure the boost pressure of turbochargers, to monitor the oil pressure in suspension systems, to detect tire pressure in real-time, and to measure the combustion pressure of the mixture in the cylinder.

Body Perception: Position Sensors

Position sensors are devices that measure the position of moving or operating elements. The working principles of automotive position sensors mainly include Hall effect, magnetoresistive effect, photoelectric, capacitive, and thermal types. They can be classified into crankshaft position sensors, throttle position sensors, vehicle height and angle position sensors, liquid level sensors, orientation sensors, seat position sensors, etc., based on their usage.

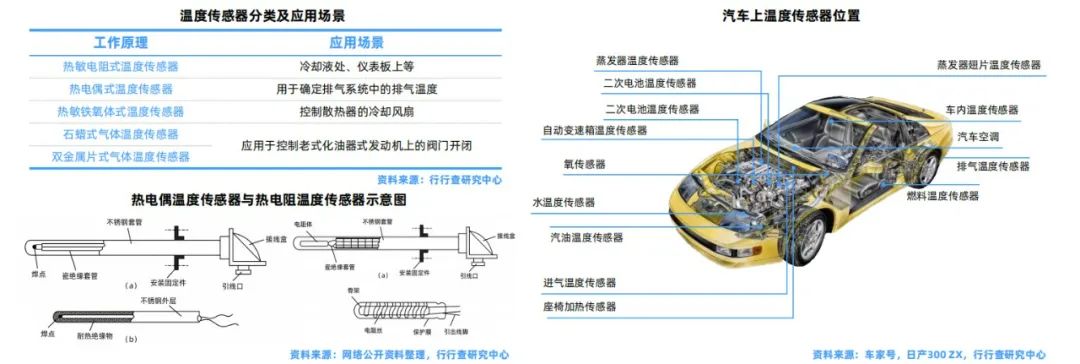

Body Perception: Automotive Temperature Sensors

Temperature Sensors: The most widely used temperature sensors in automotive applications are thermistor temperature sensors. Automotive temperature sensors convert temperature signals into usable output signals, which can be classified into thermistor, thermocouple, and thermoresistive types based on their working principles, among which thermistor temperature sensors are the most widely used. Depending on the application scenarios, thermistor temperature sensors can be categorized into intake temperature sensors, coolant temperature sensors, internal and external temperature sensors, evaporator outlet temperature sensors, and exhaust temperature sensors.

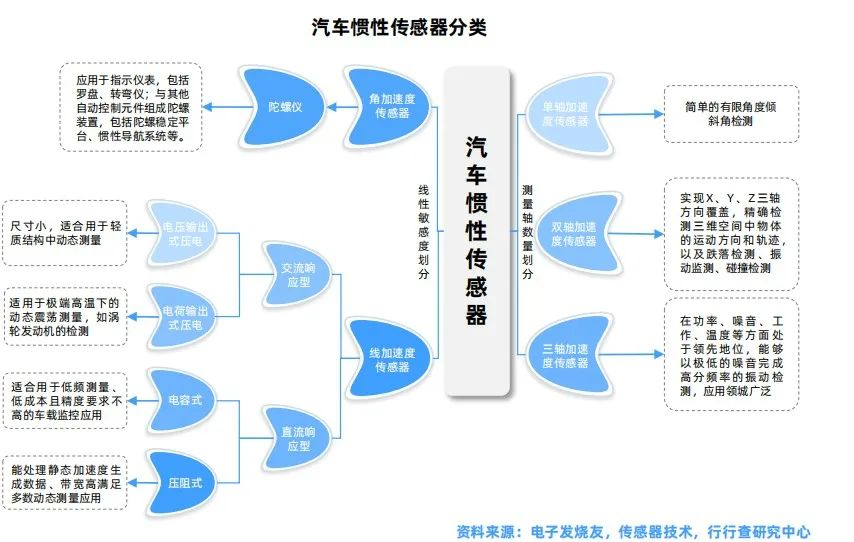

Body Perception: Automotive Inertial Sensors

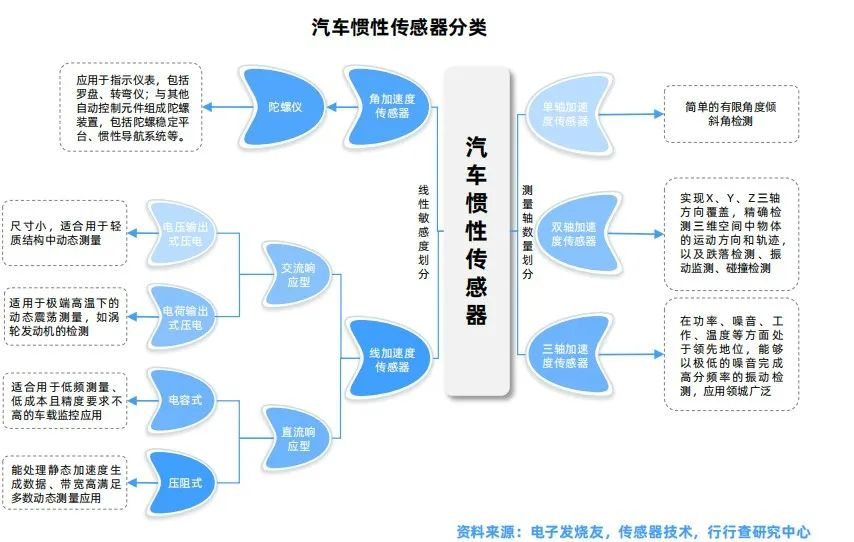

Inertial Sensors are devices used to measure an object’s motion parameters in an inertial space. Based on whether the motion is linear, inertial sensors can be classified into linear acceleration sensors and angular acceleration sensors; they can also be categorized based on the number of measurement axes into single-axis, dual-axis, and tri-axis acceleration sensors. Combining linear acceleration sensors, angular acceleration sensors, and other measuring elements can meet the needs of automotive safety control and navigation systems, with specific applications including automotive airbags, ABS anti-lock braking systems, electronic stability programs (ESP), and electronic suspension systems.

Linear Acceleration Sensors: Linear acceleration sensors, also known as acceleration sensors, are devices that measure the inertial forces inside the sensor to calculate acceleration data. Depending on their working principles, acceleration sensors can be classified into AC response and DC response types. AC acceleration sensors typically use piezoelectric elements, divided into voltage output piezoelectric sensors and charge output piezoelectric sensors; DC acceleration sensors can be categorized into capacitive and resistive types based on their sensing technologies.

Angular (Acceleration) Sensors: Angular acceleration sensors, also known as angular velocity sensors, are essentially gyroscopes. Gyroscopes are devices that detect angular motion around one or two axes that are orthogonal to the rotation axis, using momentum (generated by a rotating rotor), and can work together with accelerometers to form an inertial navigation system, which is a major factor determining the accuracy of inertial navigation systems.

Body Perception: Airflow Sensors

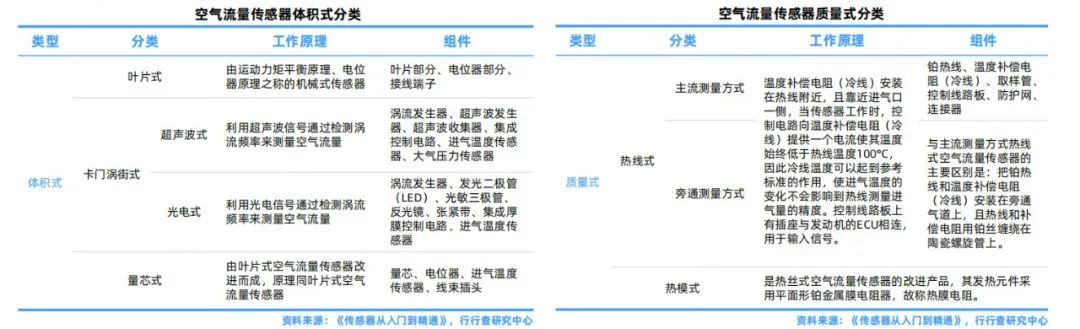

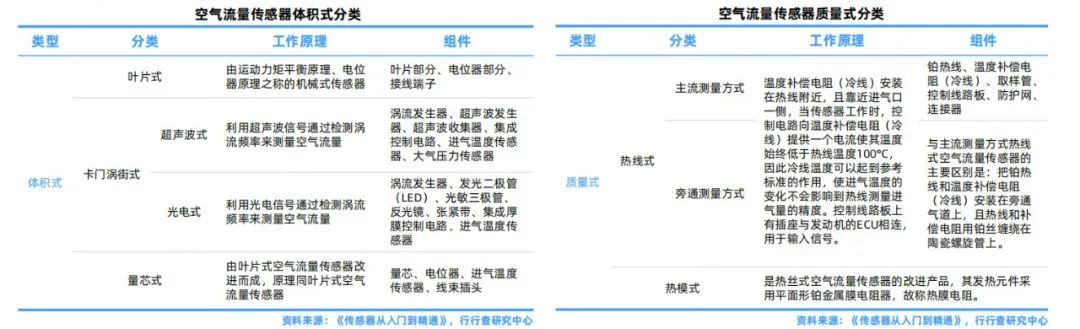

Airflow sensors, also known as air flow meters, are used to detect the amount of air entering the engine and are one of the most important sensors for fuel-injected engines. Airflow sensors are typically installed in the intake pipe, converting intake volume signals into electrical signals sent to the ECU to determine fuel injection quantity and ignition timing. For gasoline fuel-injected engines, electronic adjustments are made to ensure they achieve the optimal mixture concentration under various rotational conditions, requiring measurement of the amount of air entering the engine at all times as a key basis for the ECU’s calculation (adjustment) of fuel injection quantity. If the airflow sensor or its circuit fails, the ECU will not receive a good intake signal and will not be able to adjust the fuel injection quantity properly, leading to either too rich or too lean a mixture, causing abnormal engine operation and potentially damaging components. Airflow sensors are classified into volumetric and mass types, with volumetric types including blade-type, Karman vortex type, and core type, and mass types including hot wire and hot film.

Body Perception: Gas Sensors

Gas sensors are devices that detect the type and concentration of gases. Gas sensors can be categorized based on their technological principles into semiconductor gas sensors, solid electrolyte gas sensors, catalytic combustion gas sensors, electrochemical gas sensors, and optical gas sensors; based on the type of gas being measured, gas concentration sensors used in vehicles can be classified into oxygen sensors, NOX sensors, lean mixture sensors, smoke concentration sensors, and diesel smoke sensors.

Body Perception: MEMS Solutions

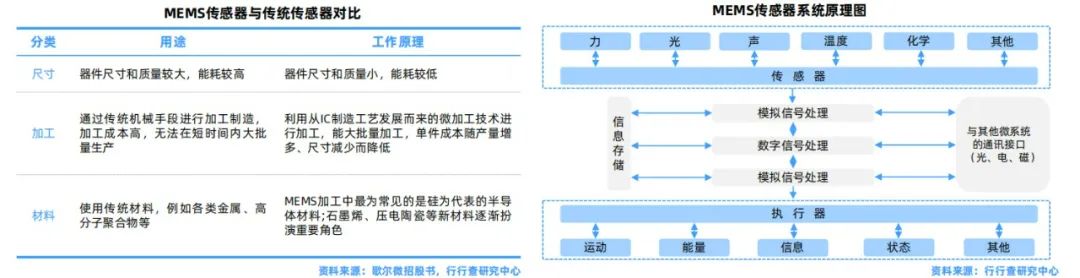

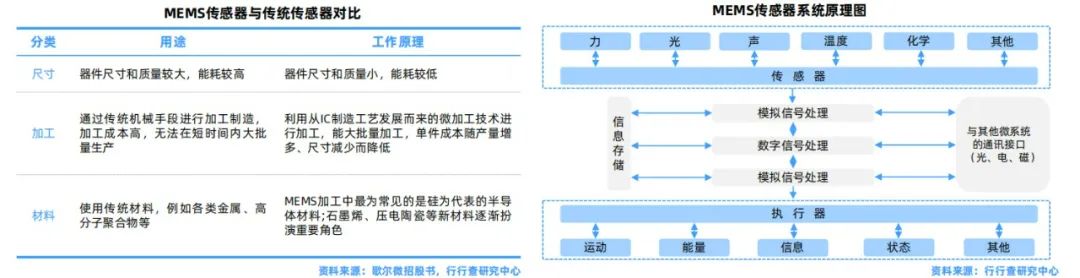

Body perception sensors are distributed throughout the vehicle and are widely used in power systems (the three electric systems of new energy vehicles), chassis systems, and body systems, achieving the perception of the vehicle’s own information and making decisions and executions, serving as the “nerve endings” of the vehicle. They are currently well-developed, primarily using MEMS sensors. MEMS systems, or Micro-Electro-Mechanical Systems, are micro or nano-level devices or systems that can be mass-produced, integrating micro sensors, actuators, mechanical structures, power sources, signal processing, control circuits, high-performance electronic components, interfaces, and communication. MEMS sensors are a cutting-edge research field developed based on microelectronic technology and are new types of sensors manufactured using microelectronic and micromechanical processing technologies.

Compared to traditional sensors, they have the characteristics of small size, light weight, low cost, low power consumption, high reliability, suitability for mass production, and ease of integration and intelligence. Additionally, the micron-level characteristic dimensions allow them to perform functions that some traditional mechanical sensors cannot achieve. MEMS sensors do not have standardized production processes; each MEMS sensor is produced for specific downstream scenarios. According to their working principles, MEMS sensors can be classified into physical, chemical, and biological types, covering almost all types of automotive sensors.

Body Perception: Gas Sensors

Gas sensors are devices that detect the type and concentration of gases. Gas sensors can be categorized based on their technological principles into semiconductor gas sensors, solid electrolyte gas sensors, catalytic combustion gas sensors, electrochemical gas sensors, and optical gas sensors; based on the type of gas being measured, gas concentration sensors used in vehicles can be classified into oxygen sensors, NOX sensors, lean mixture sensors, smoke concentration sensors, and diesel smoke sensors.

Body Perception: MEMS Solutions

Body perception sensors are distributed throughout the vehicle and are widely used in power systems (the three electric systems of new energy vehicles), chassis systems, and body systems, achieving the perception of the vehicle’s own information and making decisions and executions, serving as the “nerve endings” of the vehicle. They are currently well-developed, primarily using MEMS sensors. MEMS systems, or Micro-Electro-Mechanical Systems, are micro or nano-level devices or systems that can be mass-produced, integrating micro sensors, actuators, mechanical structures, power sources, signal processing, control circuits, high-performance electronic components, interfaces, and communication. MEMS sensors are a cutting-edge research field developed based on microelectronic technology and are new types of sensors manufactured using microelectronic and micromechanical processing technologies.

Compared to traditional sensors, they have the characteristics of small size, light weight, low cost, low power consumption, high reliability, suitability for mass production, and ease of integration and intelligence. Additionally, the micron-level characteristic dimensions allow them to perform functions that some traditional mechanical sensors cannot achieve. MEMS sensors do not have standardized production processes; each MEMS sensor is produced for specific downstream scenarios. According to their working principles, MEMS sensors can be classified into physical, chemical, and biological types, covering almost all types of automotive sensors.

Taking the manufacturing process of MEMS pressure sensors as an example, it requires the preparation of pressure-sensitive resistors and metal interconnects on silicon wafers through processes such as silicon nitride thin film deposition, photolithography, and metal ion implantation. After that, anisotropic wet etching is performed on the back of the silicon wafer to control the thickness of the pressure-sensitive membrane by adjusting the etching rate and time. Finally, glass is used to bond and support the chip structure. It is estimated that 7-8 layers of substrates are needed, and each layer must undergo deposition, photolithography, implantation, etching, etc., with very high requirements for temperature control precision and stress.

Taking the manufacturing process of MEMS pressure sensors as an example, it requires the preparation of pressure-sensitive resistors and metal interconnects on silicon wafers through processes such as silicon nitride thin film deposition, photolithography, and metal ion implantation. After that, anisotropic wet etching is performed on the back of the silicon wafer to control the thickness of the pressure-sensitive membrane by adjusting the etching rate and time. Finally, glass is used to bond and support the chip structure. It is estimated that 7-8 layers of substrates are needed, and each layer must undergo deposition, photolithography, implantation, etching, etc., with very high requirements for temperature control precision and stress.

Unlike large-scale integrated circuit products that use standardized CMOS production processes, MEMS sensor chips are essentially collections of extremely miniaturized mechanical systems and integrated circuits manufactured on silicon wafers, with highly customized production characteristics. The technological advancement of MEMS sensors is reflected not only in the design difficulty of MEMS sensor chips but also in the feasibility of the production processes for MEMS sensor chips. Leading MEMS sensor manufacturers need to possess outstanding design capabilities for extremely miniaturized mechanical systems and integrated circuits, as well as develop production processes for different sensor chips.

Environmental Perception: Onboard Cameras

Onboard cameras: Onboard cameras provide input for ADAS functions through light-sensitive imaging. Onboard cameras monitor the vehicle’s internal and external environment, converting optical signals into electrical signals and displaying images to assist the driver in driving. They are typically classified into monocular cameras, binocular cameras, and wide-angle cameras, installed in various locations such as the front, surround, rear, side, and interior of the vehicle. The main function of the camera is to perceive the external environment, providing video signal input for collision warnings, pedestrian detection, and other ADAS functions.

Onboard cameras mainly consist of lens groups, image sensors (CMOS), and digital image signal processing (DSP). The image sensor is the core technology of the onboard camera. The lens group, adhesive materials, and image sensor are packaged to form a lens module, which transmits the optoelectronic signals to the DSP for image signal processing; the DSP converts the analog signals into digital signals, which are then integrated with the lens module packaging to form the terminal system.

Unlike large-scale integrated circuit products that use standardized CMOS production processes, MEMS sensor chips are essentially collections of extremely miniaturized mechanical systems and integrated circuits manufactured on silicon wafers, with highly customized production characteristics. The technological advancement of MEMS sensors is reflected not only in the design difficulty of MEMS sensor chips but also in the feasibility of the production processes for MEMS sensor chips. Leading MEMS sensor manufacturers need to possess outstanding design capabilities for extremely miniaturized mechanical systems and integrated circuits, as well as develop production processes for different sensor chips.

Environmental Perception: Onboard Cameras

Onboard cameras: Onboard cameras provide input for ADAS functions through light-sensitive imaging. Onboard cameras monitor the vehicle’s internal and external environment, converting optical signals into electrical signals and displaying images to assist the driver in driving. They are typically classified into monocular cameras, binocular cameras, and wide-angle cameras, installed in various locations such as the front, surround, rear, side, and interior of the vehicle. The main function of the camera is to perceive the external environment, providing video signal input for collision warnings, pedestrian detection, and other ADAS functions.

Onboard cameras mainly consist of lens groups, image sensors (CMOS), and digital image signal processing (DSP). The image sensor is the core technology of the onboard camera. The lens group, adhesive materials, and image sensor are packaged to form a lens module, which transmits the optoelectronic signals to the DSP for image signal processing; the DSP converts the analog signals into digital signals, which are then integrated with the lens module packaging to form the terminal system.

CMOS image sensor technology (CIS) integrates analog and digital circuits, serving as an optical sensor and the core component of the camera module, critically influencing the camera’s light perception and image quality. It mainly consists of four components: micro-lenses, color filters (CF), photodiodes (PD), and pixel design. Based on the components, they can be classified into complementary metal-oxide-semiconductor (CMOS) image sensors and charge-coupled device (CCD) image sensors. A typical CMOS image sensor (CIS) consists of multiple modules, each performing different functions, where the pixel array converts optoelectronic signals, the timing control circuit processes the electrical signals, and the analog-to-digital conversion converts the signals into the required digital signals for final output.

Environmental Perception: Ultrasonic Radar

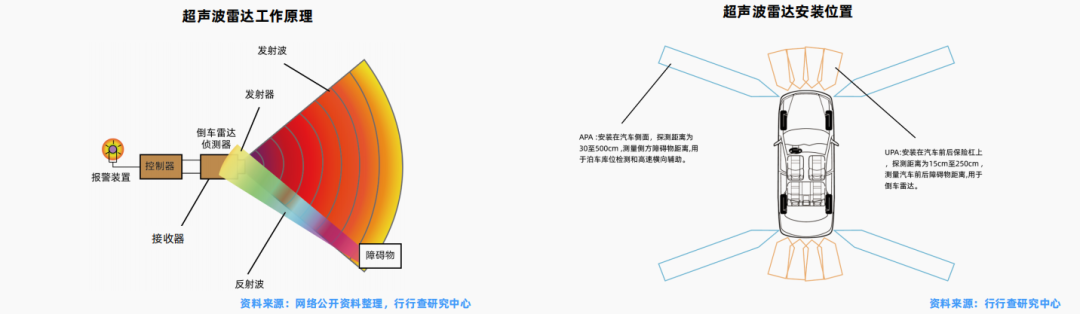

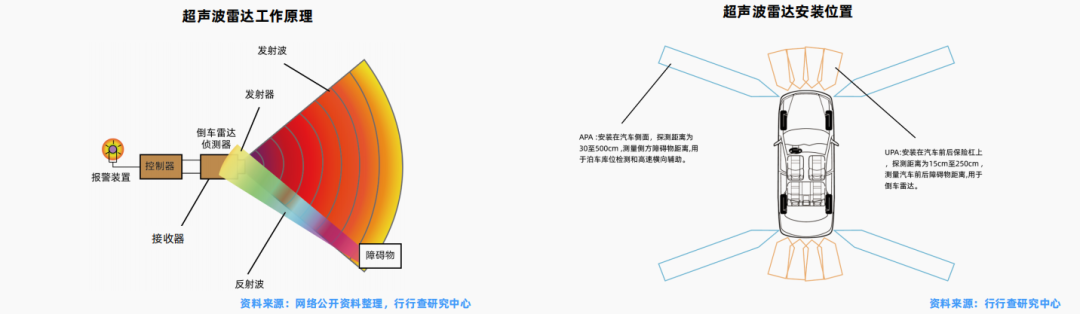

Ultrasonic Radar: Ultrasonic radar is commonly used for parking assistance warnings and blind spot collision warnings, being the mainstream sensor for automatic parking systems. The working principle of ultrasonic radar involves emitting and receiving ultrasonic waves, calculating distance based on the time of flight of the ultrasonic waves. The working frequencies of automotive ultrasonic radar probes are 40kHz, 48kHz, and 58kHz; higher frequencies yield greater sensitivity but narrower detection angles, so 40kHz probes are generally used.

Depending on the installation position in the vehicle, ultrasonic radar can be divided into UPA (ultrasonic parking assistance) and APA (automatic parking assistance) types; UPA is installed in the bumper to detect obstacles in front and behind the vehicle, while APA is installed on the vehicle’s side to detect side parking spaces. A single UPA ultrasonic radar can detect distances ranging from 15 to 250 cm, while a single APA ultrasonic radar can detect distances ranging from 30 to 500 cm, with a longer detection range. A complete reversing radar system requires four UPA ultrasonic sensors to be installed in the rear bumper, while an automatic parking system requires an additional four UPA and four APA ultrasonic sensors, forming a layout of four at the front (UPA), four at the sides (APA), and four at the rear (UPA).

CMOS image sensor technology (CIS) integrates analog and digital circuits, serving as an optical sensor and the core component of the camera module, critically influencing the camera’s light perception and image quality. It mainly consists of four components: micro-lenses, color filters (CF), photodiodes (PD), and pixel design. Based on the components, they can be classified into complementary metal-oxide-semiconductor (CMOS) image sensors and charge-coupled device (CCD) image sensors. A typical CMOS image sensor (CIS) consists of multiple modules, each performing different functions, where the pixel array converts optoelectronic signals, the timing control circuit processes the electrical signals, and the analog-to-digital conversion converts the signals into the required digital signals for final output.

Environmental Perception: Ultrasonic Radar

Ultrasonic Radar: Ultrasonic radar is commonly used for parking assistance warnings and blind spot collision warnings, being the mainstream sensor for automatic parking systems. The working principle of ultrasonic radar involves emitting and receiving ultrasonic waves, calculating distance based on the time of flight of the ultrasonic waves. The working frequencies of automotive ultrasonic radar probes are 40kHz, 48kHz, and 58kHz; higher frequencies yield greater sensitivity but narrower detection angles, so 40kHz probes are generally used.

Depending on the installation position in the vehicle, ultrasonic radar can be divided into UPA (ultrasonic parking assistance) and APA (automatic parking assistance) types; UPA is installed in the bumper to detect obstacles in front and behind the vehicle, while APA is installed on the vehicle’s side to detect side parking spaces. A single UPA ultrasonic radar can detect distances ranging from 15 to 250 cm, while a single APA ultrasonic radar can detect distances ranging from 30 to 500 cm, with a longer detection range. A complete reversing radar system requires four UPA ultrasonic sensors to be installed in the rear bumper, while an automatic parking system requires an additional four UPA and four APA ultrasonic sensors, forming a layout of four at the front (UPA), four at the sides (APA), and four at the rear (UPA).

With the trend of rapid penetration of onboard cameras in ADAS, a simultaneous increase in both quantity and price is expected. L2 and lower-level vehicles generally have no more than eight cameras, while L3 vehicles have eight to twelve cameras, and L4 and L5 vehicles have twelve or even more cameras.

Currently, the penetration of intelligent vehicles in the market is low, mostly at L0-L2 levels, with a generally low number of cameras per vehicle. Since 2021, the rapid popularization of ADAS functions has occurred, with several L3-level passenger vehicles being launched and delivered, gradually advancing intelligent driving from L2 to L3, and the average number of cameras per vehicle is expected to increase. In the future, as L4 and L5 become mainstream models, the average number of cameras per vehicle is expected to further rise.

Distance measurement is the most important and widely used function of ultrasonic sensors, used to perceive changes in the position and distance of obstacles or surrounding environments, being a core component of the perception layer, with primary application areas including automatic parking assistance systems (APA systems), valet parking systems (AVP systems), blind spot detection systems (BSD systems), front collision warning systems (FCW systems), reversing collision radar (PDC), rear passenger monitoring systems (ROA systems), and obstacle detection for cleaning/industrial robots/drones, liquid level detection, and foreign object detection.

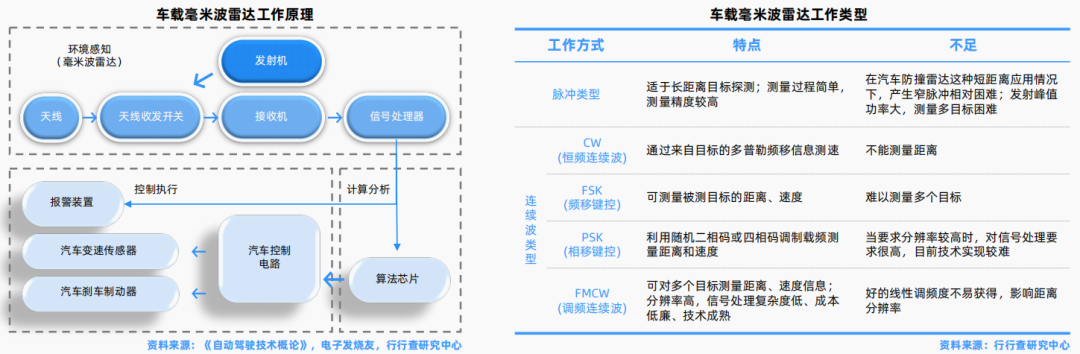

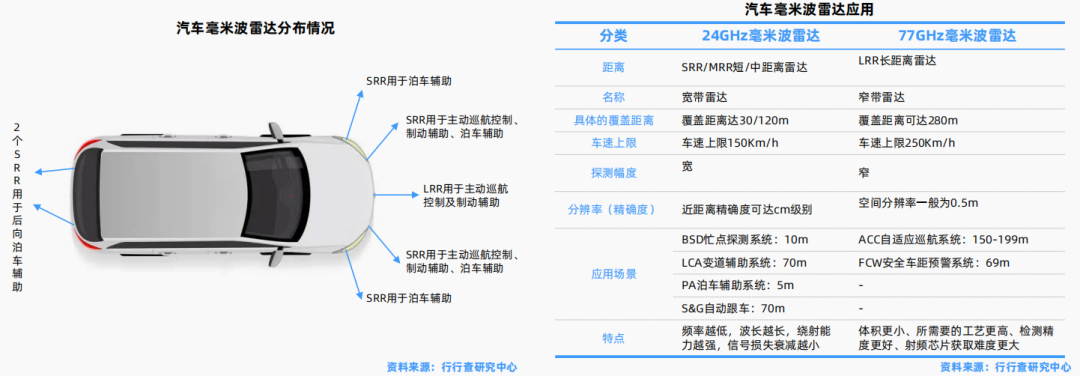

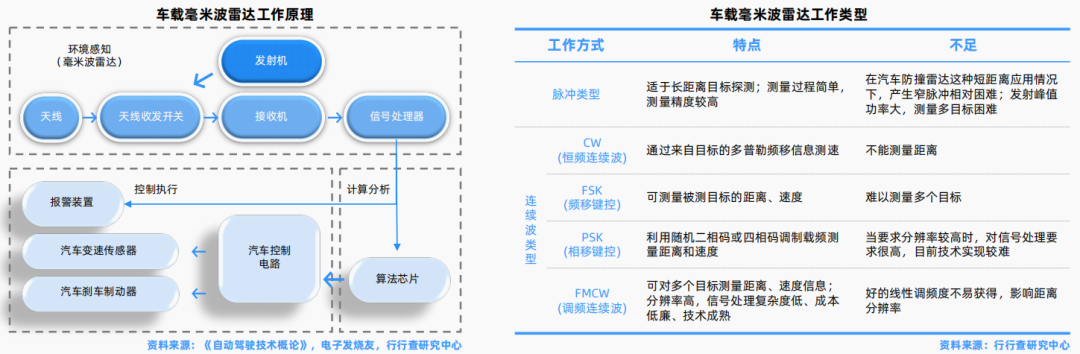

Environmental Perception: Millimeter-Wave Radar

Millimeter-Wave Radar: Millimeter-wave radar is an important component of the ADAS system and a key device for achieving intelligent driving in vehicles. Millimeter-wave radar uses millimeter waves with frequencies between 30GHz and 300GHz to illuminate targets and receive echoes, obtaining information such as distance, orientation, and speed of the target in relation to the transmitter through signal processing. Automotive millimeter-wave radar typically adopts FMCW continuous frequency modulation, usually at 24GHz and 77GHz; based on measurement distance, they can be classified into short-range SRR, mid-range MRR, and long-range LRR. The 77GHz millimeter-wave radar is usually installed at the front of the vehicle to detect objects at medium to long distances, while the 24GHz millimeter-wave radar is typically installed on the sides and rear of the vehicle for blind spot detection and parking assistance. Millimeter-wave radar is now widely used in automotive ADAS systems.

With the trend of rapid penetration of onboard cameras in ADAS, a simultaneous increase in both quantity and price is expected. L2 and lower-level vehicles generally have no more than eight cameras, while L3 vehicles have eight to twelve cameras, and L4 and L5 vehicles have twelve or even more cameras.

Currently, the penetration of intelligent vehicles in the market is low, mostly at L0-L2 levels, with a generally low number of cameras per vehicle. Since 2021, the rapid popularization of ADAS functions has occurred, with several L3-level passenger vehicles being launched and delivered, gradually advancing intelligent driving from L2 to L3, and the average number of cameras per vehicle is expected to increase. In the future, as L4 and L5 become mainstream models, the average number of cameras per vehicle is expected to further rise.

Distance measurement is the most important and widely used function of ultrasonic sensors, used to perceive changes in the position and distance of obstacles or surrounding environments, being a core component of the perception layer, with primary application areas including automatic parking assistance systems (APA systems), valet parking systems (AVP systems), blind spot detection systems (BSD systems), front collision warning systems (FCW systems), reversing collision radar (PDC), rear passenger monitoring systems (ROA systems), and obstacle detection for cleaning/industrial robots/drones, liquid level detection, and foreign object detection.

Environmental Perception: Millimeter-Wave Radar

Millimeter-Wave Radar: Millimeter-wave radar is an important component of the ADAS system and a key device for achieving intelligent driving in vehicles. Millimeter-wave radar uses millimeter waves with frequencies between 30GHz and 300GHz to illuminate targets and receive echoes, obtaining information such as distance, orientation, and speed of the target in relation to the transmitter through signal processing. Automotive millimeter-wave radar typically adopts FMCW continuous frequency modulation, usually at 24GHz and 77GHz; based on measurement distance, they can be classified into short-range SRR, mid-range MRR, and long-range LRR. The 77GHz millimeter-wave radar is usually installed at the front of the vehicle to detect objects at medium to long distances, while the 24GHz millimeter-wave radar is typically installed on the sides and rear of the vehicle for blind spot detection and parking assistance. Millimeter-wave radar is now widely used in automotive ADAS systems.

FMCW (Frequency Modulated Continuous Wave) is the most commonly used type of onboard millimeter-wave radar, adopted by Tier 1 suppliers such as Delphi, Denso, and Bosch. Onboard millimeter-wave radar emits millimeter waves through antennas, measuring parameters such as the size, speed, and distance of obstacles based on the time of flight of echoes. Millimeter-wave radar can measure multiple targets simultaneously, obtaining physical environmental information surrounding the vehicle. The 24GHz radar is mainly used for short to medium-range detection, with applications including blind spot detection, lane departure warnings, lane keeping assistance, lane change assistance, and parking assistance. The 77GHz radar is primarily aimed at medium to long-range detection of 100-250 meters, such as adaptive cruise control, collision warning indications, and emergency braking series.

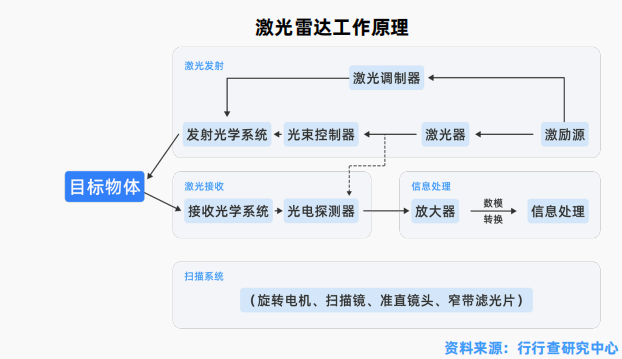

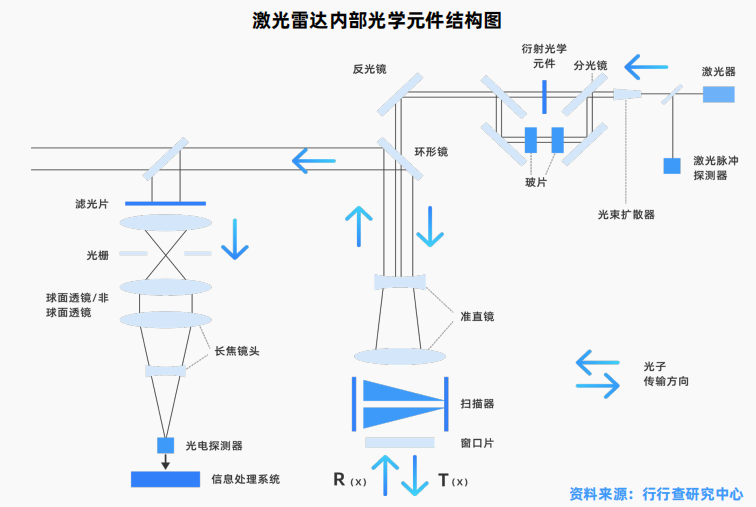

Environmental Perception: Laser Radar

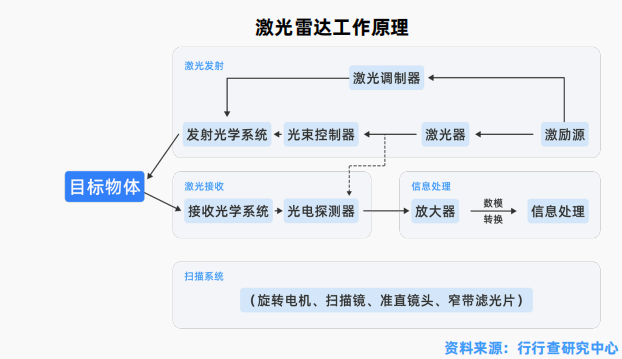

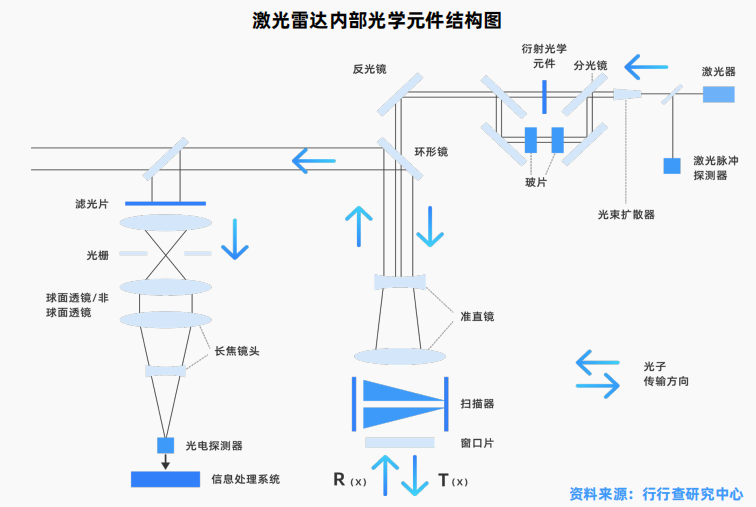

Laser Radar: Laser radar is a radar system that detects the position and speed of targets by emitting laser beams. Its working principle involves emitting detection signals (laser beams) to targets and then comparing the received signals (target echoes) with the emitted signals for appropriate processing to obtain information about the target, such as distance, orientation, height, speed, posture, and even shape, enabling the detection, tracking, and identification of targets such as airplanes and missiles. The laser emission system: the excitation source drives the laser to emit laser pulses, and the laser modulator controls the direction and number of emitted lasers through the beam controller. Finally, the laser is emitted to the target object through the emission optical system; the laser receiving system: the received optical system and photodetector receive the reflected laser from the target object, generating a receiving signal; the information processing system: the received signal is amplified and converted from analog to digital, and calculated by the information processing module to obtain the characteristics of the target’s surface shape and physical properties, ultimately building a model of the object; the scanning system: rotating at a stable speed to scan the plane, generating real-time planar map information.

FMCW (Frequency Modulated Continuous Wave) is the most commonly used type of onboard millimeter-wave radar, adopted by Tier 1 suppliers such as Delphi, Denso, and Bosch. Onboard millimeter-wave radar emits millimeter waves through antennas, measuring parameters such as the size, speed, and distance of obstacles based on the time of flight of echoes. Millimeter-wave radar can measure multiple targets simultaneously, obtaining physical environmental information surrounding the vehicle. The 24GHz radar is mainly used for short to medium-range detection, with applications including blind spot detection, lane departure warnings, lane keeping assistance, lane change assistance, and parking assistance. The 77GHz radar is primarily aimed at medium to long-range detection of 100-250 meters, such as adaptive cruise control, collision warning indications, and emergency braking series.

Environmental Perception: Laser Radar

Laser Radar: Laser radar is a radar system that detects the position and speed of targets by emitting laser beams. Its working principle involves emitting detection signals (laser beams) to targets and then comparing the received signals (target echoes) with the emitted signals for appropriate processing to obtain information about the target, such as distance, orientation, height, speed, posture, and even shape, enabling the detection, tracking, and identification of targets such as airplanes and missiles. The laser emission system: the excitation source drives the laser to emit laser pulses, and the laser modulator controls the direction and number of emitted lasers through the beam controller. Finally, the laser is emitted to the target object through the emission optical system; the laser receiving system: the received optical system and photodetector receive the reflected laser from the target object, generating a receiving signal; the information processing system: the received signal is amplified and converted from analog to digital, and calculated by the information processing module to obtain the characteristics of the target’s surface shape and physical properties, ultimately building a model of the object; the scanning system: rotating at a stable speed to scan the plane, generating real-time planar map information.

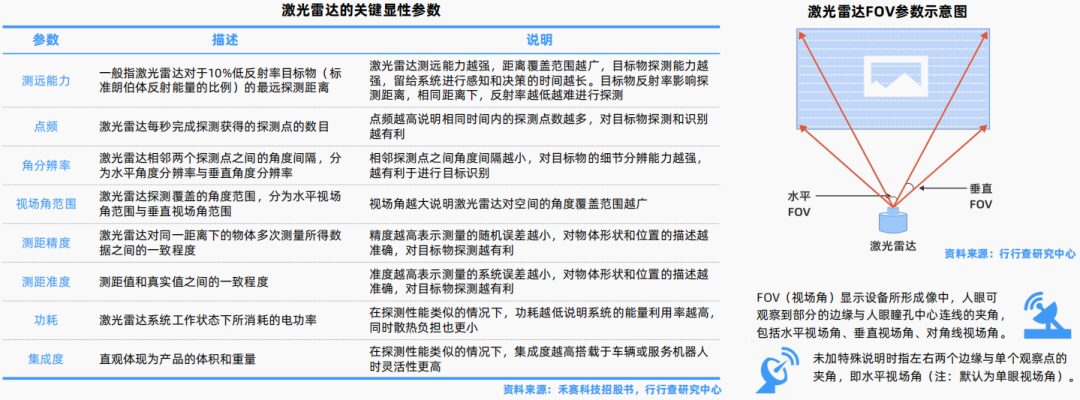

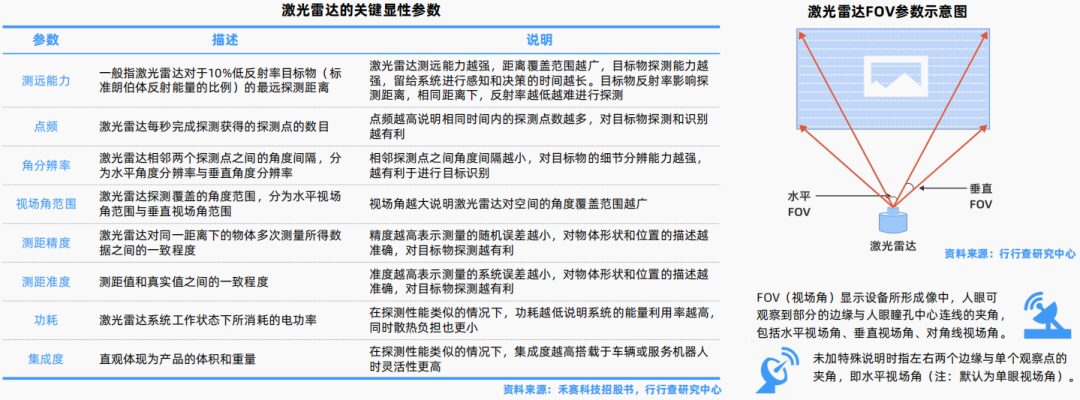

Laser radar products are primarily evaluated and compared based on explicit parameters, actual performance, and implicit indicators. Currently, due to laser radar being a new market product, there is a lack of quantifiable and reliable public data guidance for actual performance and implicit indicators. Explicit parameters mainly include measurement distance capability, point frequency, angular resolution, field of view range, distance measurement accuracy, power consumption, and integration (size and weight), which can intuitively reflect different aspects of laser radar performance.

Laser radar products are primarily evaluated and compared based on explicit parameters, actual performance, and implicit indicators. Currently, due to laser radar being a new market product, there is a lack of quantifiable and reliable public data guidance for actual performance and implicit indicators. Explicit parameters mainly include measurement distance capability, point frequency, angular resolution, field of view range, distance measurement accuracy, power consumption, and integration (size and weight), which can intuitively reflect different aspects of laser radar performance.

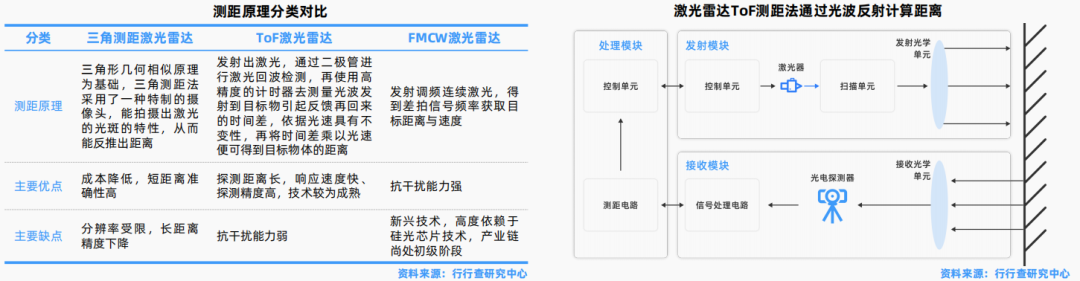

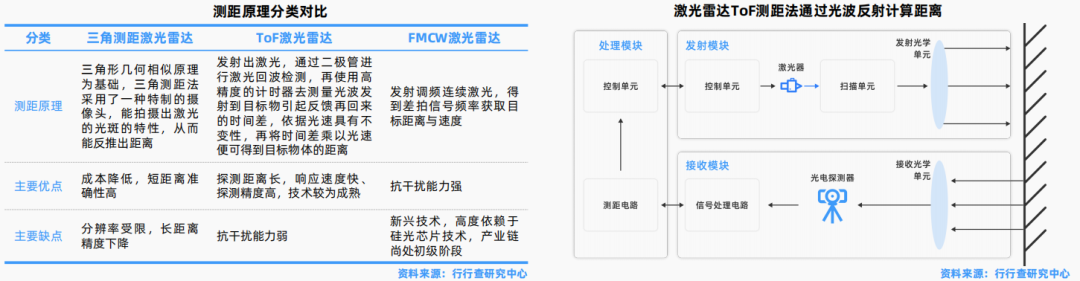

According to measurement principles, laser radars can be subdivided into triangulation, time of flight (ToF), and frequency-modulated continuous wave (FMCW). The triangulation method’s principle involves emitting laser beams to the target object, where some scattered light converges on a linear array image sensor (CCD/CMOS) to form an image. The distance to the target is then calculated based on the principle of geometric similarity of triangles. The time-of-flight method’s principle involves recording the time difference between the emitted laser and the echo signal received by the detector, dividing by 2 to directly calculate the distance between the target and the sensor. The FMCW principle involves emitting frequency-modulated continuous laser beams, obtaining the frequency of the difference signal from the echo signal delay to derive the time of flight, and using the distance formula to back-calculate the target distance and Doppler frequency formula to measure the target’s speed.

ToF ranging laser radar uses lasers as signal sources, emitting pulse lasers that scatter upon hitting surrounding objects. The receiver measures the time of flight of the reflected light waves for distance measurement, offering advantages such as fast measurement speed and strong interference resistance, but has issues like low signal-to-noise ratio and lower safety; FMCW laser radar, based on frequency-modulated waves, can calculate the speed of target objects based on wave frequency, inherently adding speed information to achieve 4D perception, but is still in the exploratory stage.

According to measurement principles, laser radars can be subdivided into triangulation, time of flight (ToF), and frequency-modulated continuous wave (FMCW). The triangulation method’s principle involves emitting laser beams to the target object, where some scattered light converges on a linear array image sensor (CCD/CMOS) to form an image. The distance to the target is then calculated based on the principle of geometric similarity of triangles. The time-of-flight method’s principle involves recording the time difference between the emitted laser and the echo signal received by the detector, dividing by 2 to directly calculate the distance between the target and the sensor. The FMCW principle involves emitting frequency-modulated continuous laser beams, obtaining the frequency of the difference signal from the echo signal delay to derive the time of flight, and using the distance formula to back-calculate the target distance and Doppler frequency formula to measure the target’s speed.

ToF ranging laser radar uses lasers as signal sources, emitting pulse lasers that scatter upon hitting surrounding objects. The receiver measures the time of flight of the reflected light waves for distance measurement, offering advantages such as fast measurement speed and strong interference resistance, but has issues like low signal-to-noise ratio and lower safety; FMCW laser radar, based on frequency-modulated waves, can calculate the speed of target objects based on wave frequency, inherently adding speed information to achieve 4D perception, but is still in the exploratory stage.

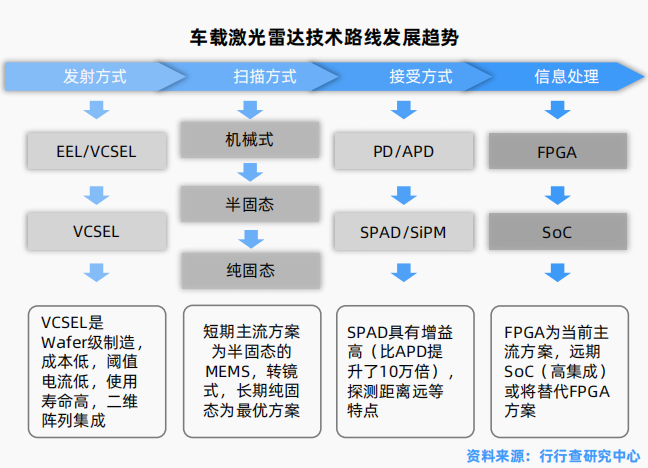

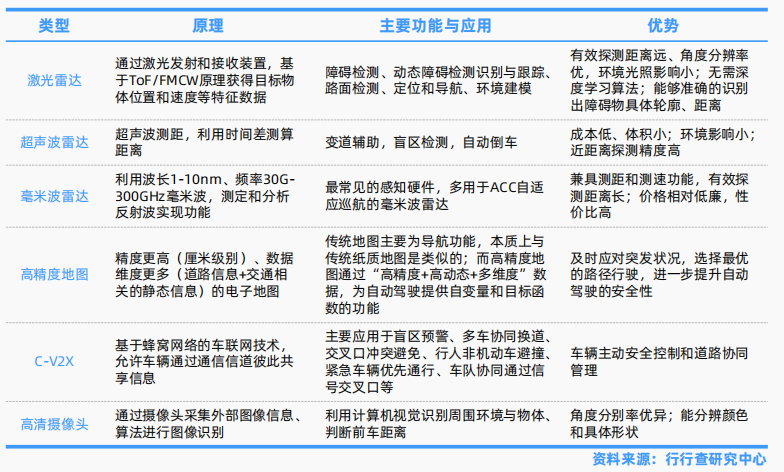

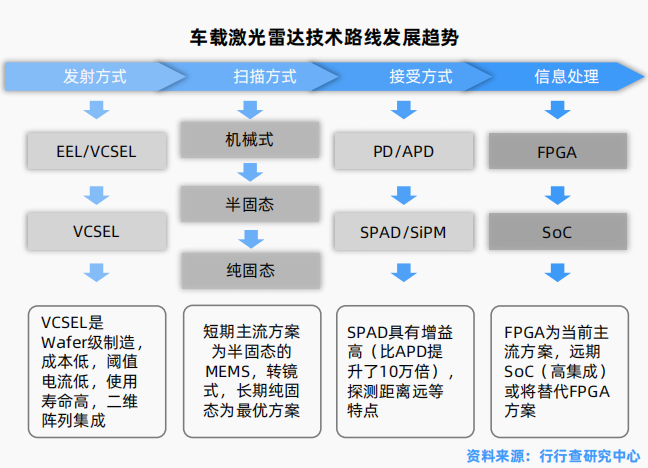

Laser radar is located in the perception layer of intelligent driving, with different sensing methods having various principles and functions, each with its own advantages and disadvantages in the automotive field. Currently, the main sensing methods include laser radar, ultrasonic radar, millimeter-wave radar, high-precision maps, C-V2X, and cameras. As a new generation of sensors, laser radar has significant advantages in detection accuracy and distance for obstacles. Onboard laser radars are classified based on the method of laser emission into EEL, VCSEL; based on scanning methods into mechanical (mechanical rotation), semi-solid (MEMS, rotating mirrors, prisms), and purely solid-state (OPA, FLASH); based on laser reception methods into PD/APD, SPAD/SiPM; and based on information processing methods into FPGA and SoC.

Laser radar is located in the perception layer of intelligent driving, with different sensing methods having various principles and functions, each with its own advantages and disadvantages in the automotive field. Currently, the main sensing methods include laser radar, ultrasonic radar, millimeter-wave radar, high-precision maps, C-V2X, and cameras. As a new generation of sensors, laser radar has significant advantages in detection accuracy and distance for obstacles. Onboard laser radars are classified based on the method of laser emission into EEL, VCSEL; based on scanning methods into mechanical (mechanical rotation), semi-solid (MEMS, rotating mirrors, prisms), and purely solid-state (OPA, FLASH); based on laser reception methods into PD/APD, SPAD/SiPM; and based on information processing methods into FPGA and SoC.

We welcome angel round and A round enterprises from the entire automotive industry chain (including the electrification industry chain) to join the group(Friendly connections with 700 automotive investment institutions including top-tier institutions; some quality projects will be selected for thematic roadshows to existing institutions); There are communication groups for leaders of science and technology innovation companies, automotive industry complete vehicles, automotive semiconductors, key components, new energy vehicles, intelligent connected vehicles, aftermarket, automotive investment, autonomous driving, vehicle networking, etc., with dozens of groups. Please scan the administrator’s WeChat to join the group (please indicate your company name)