Warm reminder: For friends who like the SMT Top Networking Circle public account, please note! According to the new regulations for public account push notifications, please set the SMT Top Networking Circle public account as “Starred” or “PinnedTop“, so that you can receive the valuable content we share every day!

Warm reminder: For friends who like the SMT Top Networking Circle public account, please note! According to the new regulations for public account push notifications, please set the SMT Top Networking Circle public account as “Starred” or “PinnedTop“, so that you can receive the valuable content we share every day!

2020 New Platform

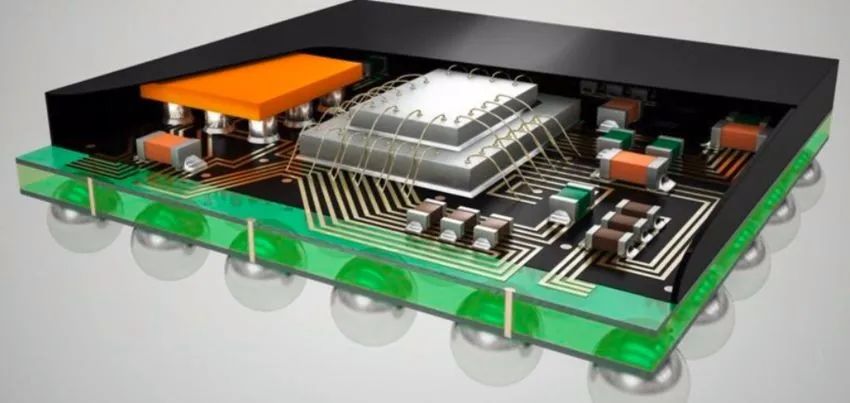

PCBA Circuit Board Component Pull and Push Strength Testing Method

(Click the video below to watch)

↓ ↓

↓

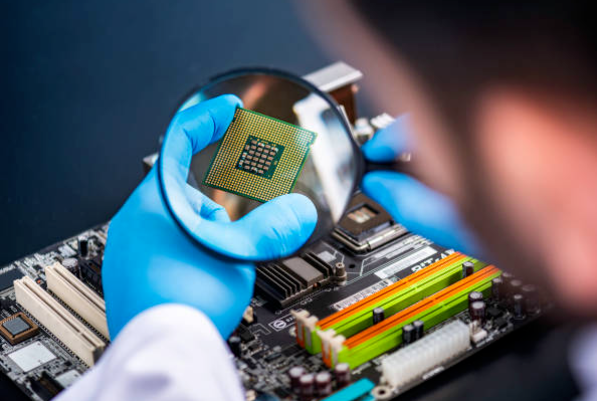

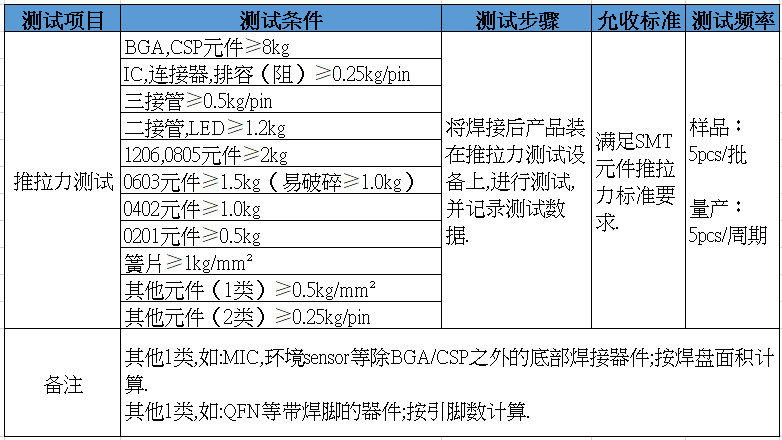

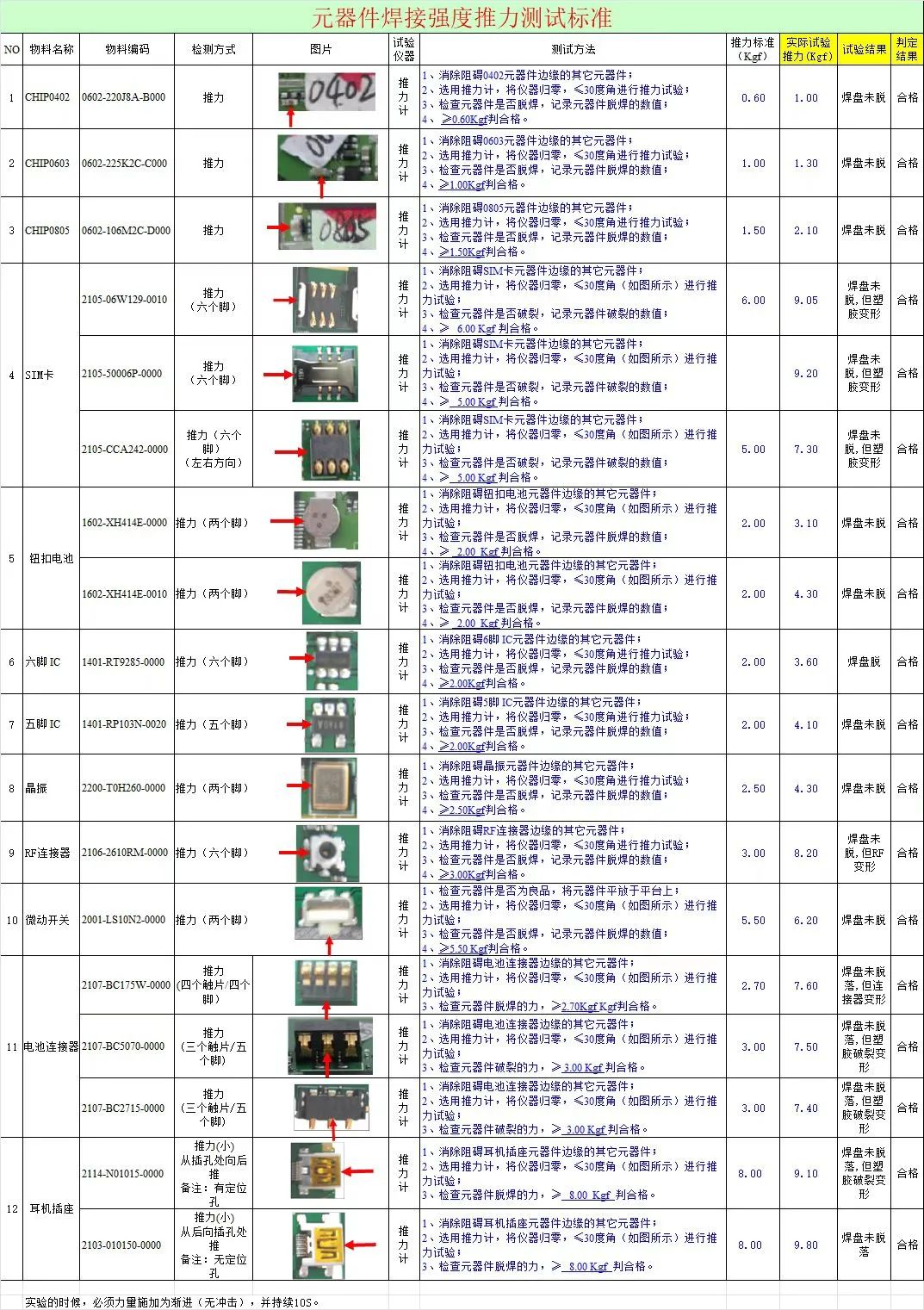

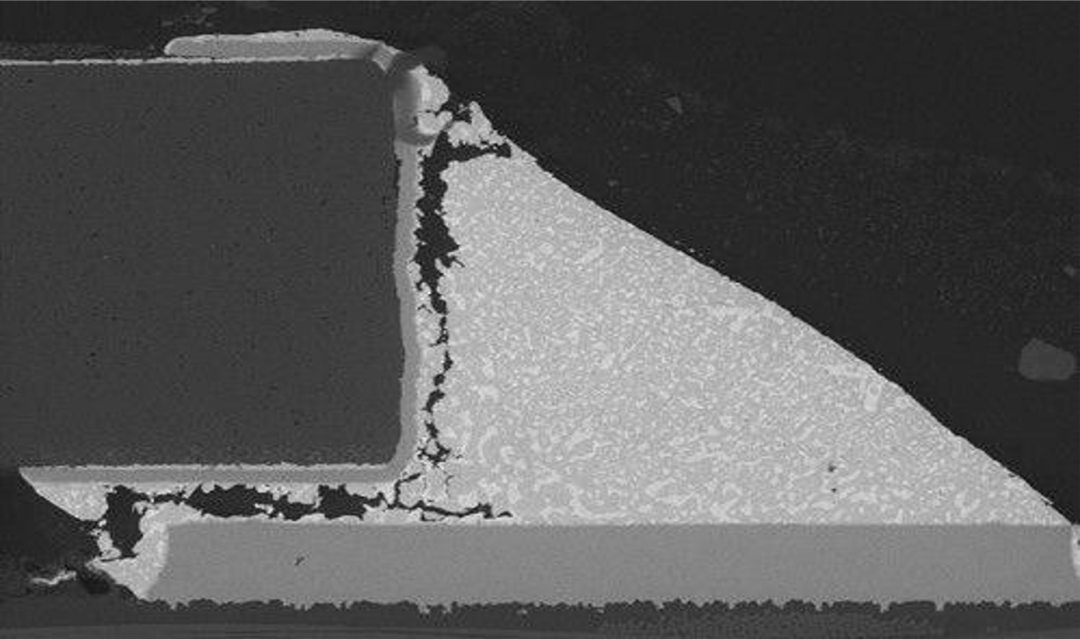

Why Perform Pull and Push Strength Testing? PCBA electronic components typically experience mechanical stress at solder joints or components due to vibrations, impacts, and bending during soldering, transportation, and usage, which can ultimately lead to solder joint or component failure. Pull and push strength testing can simulate the mechanical failure model of solder joints, analyze the causes of solder joint or component failure, and evaluate the reliability of materials.PCBA Circuit Board Component Soldering Strength Pull and Push Strength Determination Standards(Testing Basis: GJB 548, JIS Z 3198)

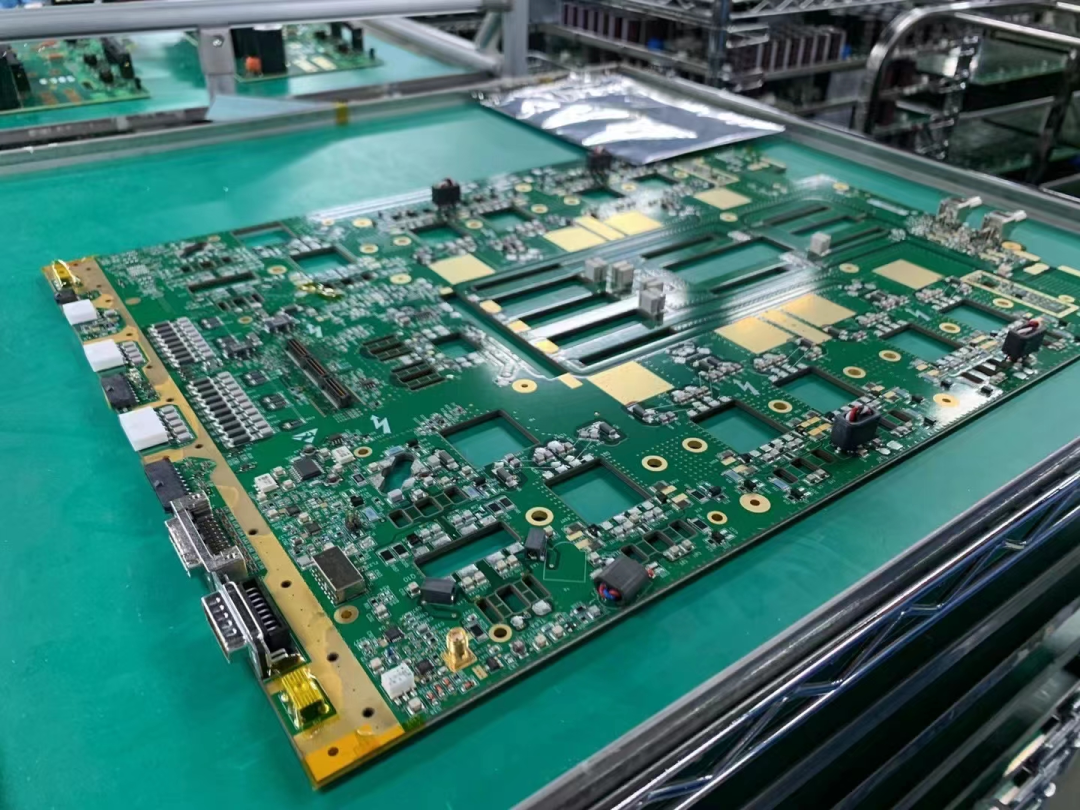

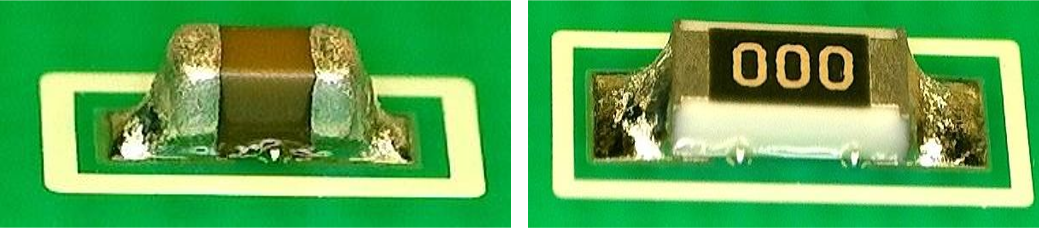

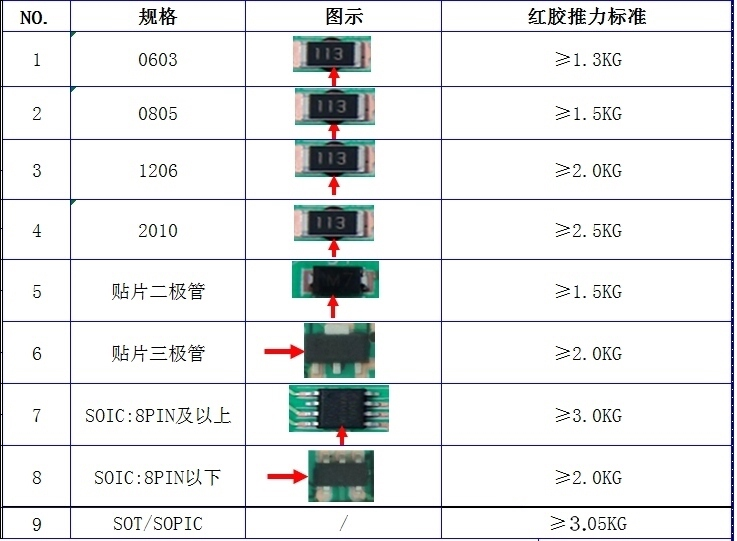

PCBA electronic components typically experience mechanical stress at solder joints or components due to vibrations, impacts, and bending during soldering, transportation, and usage, which can ultimately lead to solder joint or component failure. Pull and push strength testing can simulate the mechanical failure model of solder joints, analyze the causes of solder joint or component failure, and evaluate the reliability of materials.PCBA Circuit Board Component Soldering Strength Pull and Push Strength Determination Standards(Testing Basis: GJB 548, JIS Z 3198) For SMT chip resistors and capacitors, the installation quality can be evaluated using methods from GJB548 testing methods, such as (2019 chip shear strength, GJB548 method 2027 chip bonding strength, GJB548 method 2030 chip bonding ultrasonic testing, and GJB548 method 2012 X-ray photography).

For SMT chip resistors and capacitors, the installation quality can be evaluated using methods from GJB548 testing methods, such as (2019 chip shear strength, GJB548 method 2027 chip bonding strength, GJB548 method 2030 chip bonding ultrasonic testing, and GJB548 method 2012 X-ray photography).

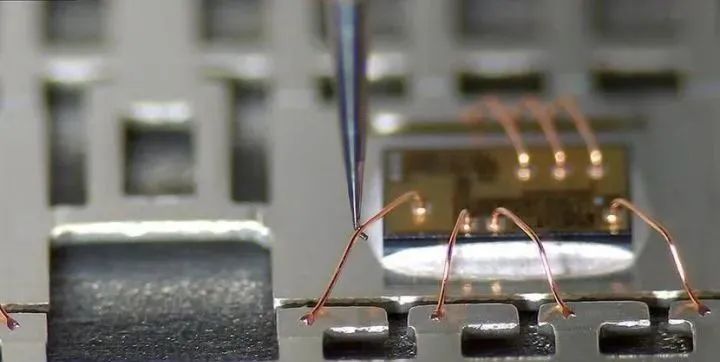

Among them, the GJB548 method 2019 chip shear strength test directly reflects the quality of the soldering or welding between chip resistors, capacitors, and the substrate, indicating the quality of the metallization of the resistor and capacitor terminals, or the quality of the soldering or bonding process control, or the quality of the metallized surface in the installation area of resistors and capacitors on the substrate. Pull and push strength testing is an essential dynamic mechanical test for measuring the fixing strength and bonding capability of components. It has strong expandability, allowing for comparison of solder joint strength at different rates and push knife heights; its values are efficient and precise, detecting material strength through constant speed motion, providing an intuitive and effective way to assess solder joint reliability.

Pull and push strength testing is an essential dynamic mechanical test for measuring the fixing strength and bonding capability of components. It has strong expandability, allowing for comparison of solder joint strength at different rates and push knife heights; its values are efficient and precise, detecting material strength through constant speed motion, providing an intuitive and effective way to assess solder joint reliability.

(Click the video below to watch)

↓ ↓

↓

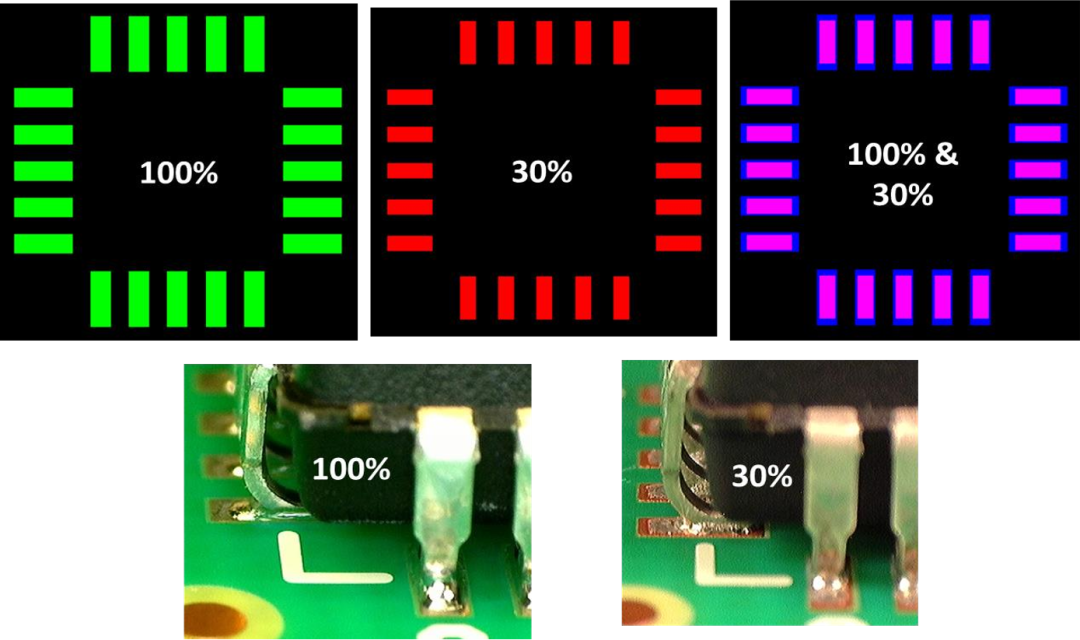

Shear & Pull Strength

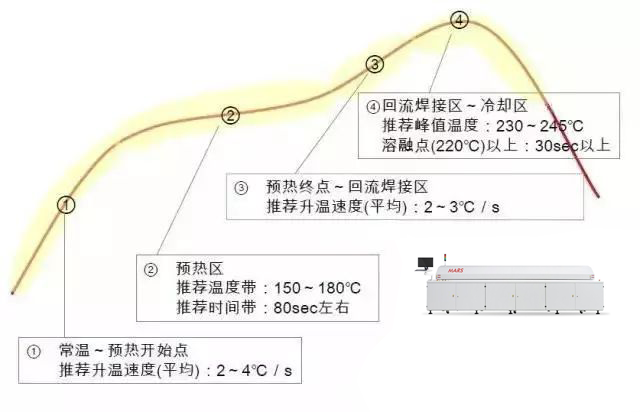

SMT Component Soldering Strength Pull and Push Value Calculation

Reference Documents: IEC 68-2-21 and JIS Z3198-6, mainly based on soldering area determination.

PCBA Circuit Board Component Soldering Red Glue Curing Strength Pull and Push Determination Standards

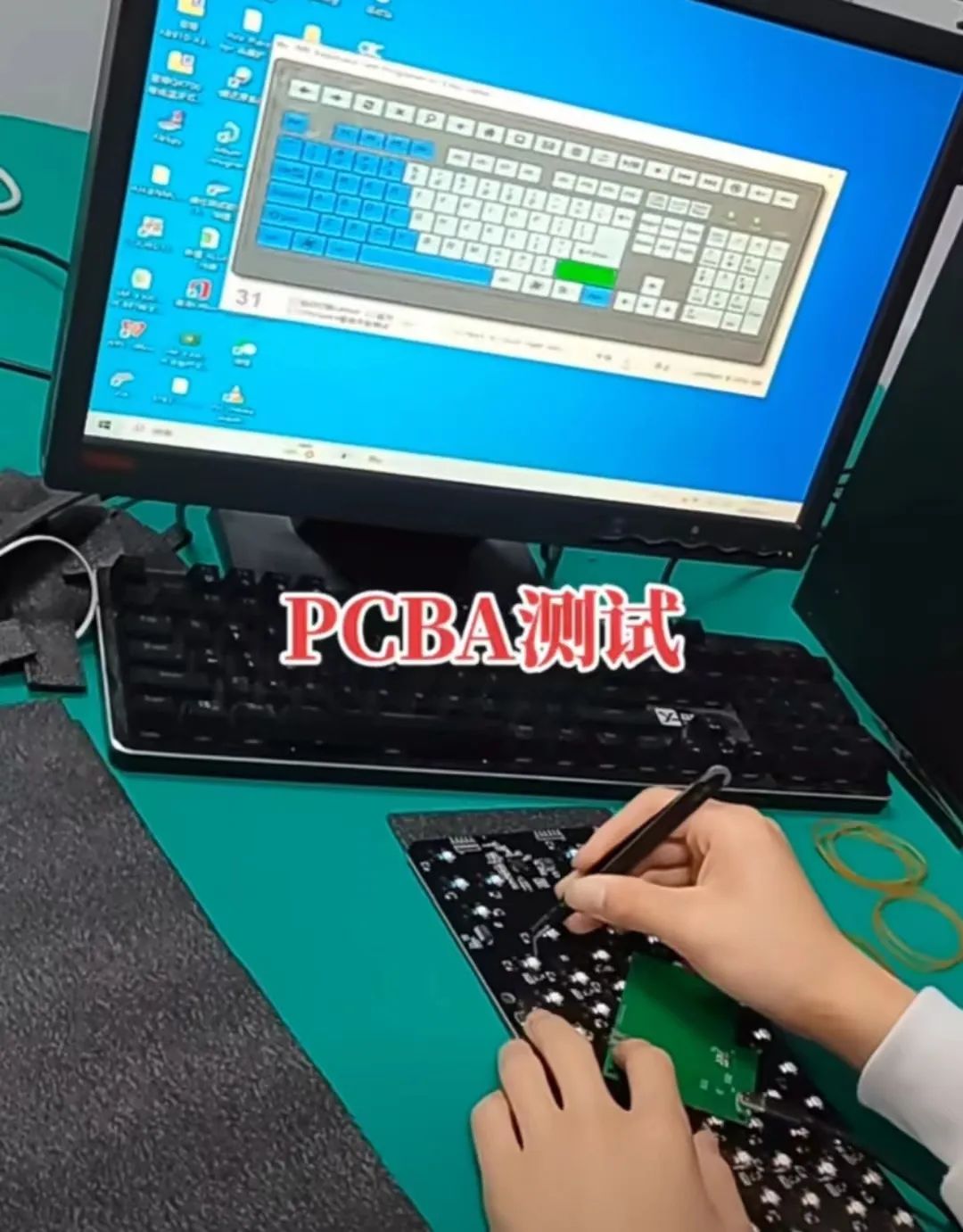

PCBA Pull and Push Strength Testing Method