Click the blue text to follow us

In the PCBA processing industry, the circulation of counterfeit electronic components not only leads to a decline in product quality but may also pose serious safety risks, affecting the company’s reputation and damaging customer trust. Therefore, identifying and rejecting counterfeit components has become a key step for PCBA factories to ensure production quality and customer satisfaction.Importance of Identifying Counterfeit Electronic ComponentsCounterfeit electronic components often enter the market in the form of refurbished old parts or fake labels. Since these components cannot meet original factory standards, products using counterfeit components may experience performance degradation and shortened lifespan. By identifying counterfeit components, production quality can be improved, and customer trust can be enhanced, maintaining the company’s market reputation.Common Methods for Identifying Counterfeit Electronic Components1. Visual InspectionProcedure:– Microscope Inspection: Use a microscope to carefully examine the appearance of the components, looking for scratches, solder residue, and other anomalies. Counterfeit components often show signs of refurbishment, such as scratches or residual solder.– Observe Package Integrity: The packaging of counterfeit components is usually rough, with defects such as uneven surfaces, cracks, or bubbles.Notes: Visual inspection primarily involves intuitive judgment of the component’s surface using the naked eye and a microscope. Although no special instruments are required, it can only identify obvious inferior components. For components that require further confirmation, other methods can be combined for inspection.Experience Sharing: In actual operations, we found multiple scratches on a batch of transistors, and after further testing, confirmed that these were refurbished parts, which were removed from the supply chain.2. Marking InspectionProcedure:– Marking Integrity: Check whether the markings (such as model number, batch number, trademark) on the components are clear and complete. The markings on counterfeit components often have issues such as blurriness or inconsistent fonts.– Compare Markings with Database: Compare the marking information with the technical documentation released by the original manufacturer to see if the markings conform to the original factory specifications, checking for any anomalies in color and font.Notes: Counterfeit manufacturers usually cannot fully replicate the characteristics of original factory markings, so original factory data can be used for detailed comparison. It should be noted that some counterfeit items may have their markings manually altered, making identification more difficult.Experience Sharing: During one inspection, we found that the font of the model and batch number of a certain brand IC was too bold, and after confirming with the original manufacturer, it was identified as a counterfeit item.3. X-ray InspectionProcedure:– Internal Structure Inspection: Use X-ray equipment to view the internal structure of the components, checking whether the pin connections and internal circuits are consistent with the original factory structure.– Solder Joint Comparison: Observe whether the solder joints are uniform; some counterfeit components may exhibit uneven solder joints, or even cold solder or dry solder.Notes: X-ray inspection can identify whether the internal structure is consistent with the original factory design, but this method is relatively expensive and suitable for critical component inspections.Experience Sharing: Through X-ray inspection, we discovered that the pin soldering of a batch of memory modules did not match the original factory specifications, proving them to be refurbished parts, thus preventing non-conforming products from entering the production line.4. Electrical Performance TestingProcedure:– Key Parameter Testing: For commonly used components such as resistors and transistors, test their resistance, current gain, and other key parameters to see if they meet original factory specifications.– Temperature and Load Testing: Counterfeit components often cannot withstand high temperatures and loads; conducting relevant tests can further screen out inferior products.Notes: Electrical performance testing requires professional testing equipment and technicians, and testing conditions must meet original factory standards.Experience Sharing: During the testing of a batch of diodes, we found that their current gain was below the original factory specifications, confirming them as counterfeit components, effectively avoiding product failures due to substandard performance.5. Original Manufacturer Traceability VerificationProcedure:– Procurement Verification: Purchase components through legitimate channels and retain relevant procurement proofs to ensure reliable material sources.– Verify with Original Manufacturer: Directly contact the original manufacturer for batch and authenticity confirmation of suspicious components to ensure the original identity of the materials.Notes: For high-value or critical components, it is recommended to directly contact the original manufacturer for traceability to ensure the authenticity of the procurement chain.Experience Sharing: We encountered a batch of ICs with correct model numbers but abnormal performance, and after confirming with the original manufacturer, they were identified as counterfeit products. This verification further strengthened our material quality management.

In the PCBA processing process, identifying counterfeit electronic components through methods such as visual inspection, marking inspection, X-ray inspection, electrical performance testing, and original manufacturer traceability verification not only ensures product quality but also effectively enhances customer trust. The identification of counterfeit electronic components is not the application of a single method but a combination of various methods. Choosing appropriate detection means based on actual conditions helps build an efficient quality management system. The efforts of PCBA factories in ensuring material quality are the important foundation for winning market and customer trust.

Summer, loading…

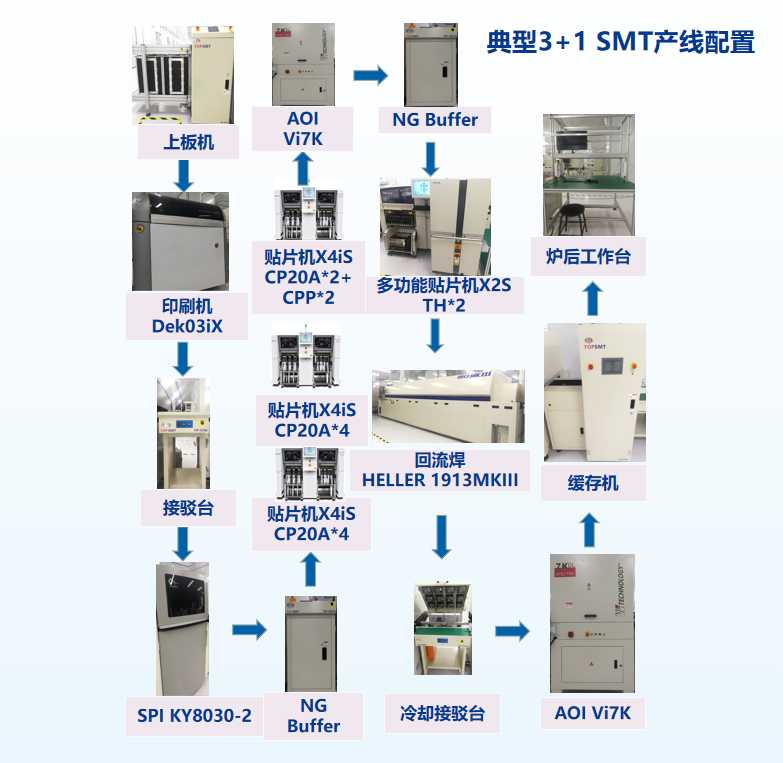

Intelli Electronics Production Line Scale

(1) 24 high-end SMT lines from ASM

(2) 8 Panasonic automatic insertion machines

(3) 4 lead-free wave soldering lines, expandable to 8 lines

(4) 8 assembly lines, expandable to 16 lines, 4 packaging lines, expandable to 8 lines

(5) Actual placement capacity of about 3 million points per hour, with a monthly capacity of up to 1.7 billion points

(6) All equipment can connect to the MES system

(7) Each SMT line is equipped with SPI/AOI inspection equipment

(8) Each SMT line is equipped with SPI/AOI post-NG buffer for fully automated connected production

(9) 1+1, 2+1, 3+1, dual-track production line layout can meet the production needs of different products, optimizing reasonably

(10) Reflow soldering with 13 temperature zones, nitrogen filling available

Business Consultation: Mr. Li 17870016160

Company Phone: 0794-7878288Company Fax: 0794-7878288Email: [email protected]

Company Website: www.intelli40.comAddress: Building 8-9, Linchuan High-tech Industrial Park, Fuzhou City, Jiangxi Province

Long press to recognize the QR code and follow us