We provide high-quality services for microcontrollers, PLCs, circuit boards, controllers/boxes, instruments, electromechanical equipment or systems, automation, industrial control, sensors, data acquisition, self-control systems, control systems, IoT, electronic products, software, and APP development and design customization (business www.yonko-tech.com). When working on projects, removing components from circuit boards is sometimes necessary. Desoldering components is not particularly difficult, but it is not always easy either.

For surface-mounted components, it is relatively straightforward; a hot air gun can blow the chip off easily, and the pads remain quite clean. However, through-hole components are a bit more troublesome. While it is easy to remove the through-hole components, cleaning the pads can be a bit of a hassle.

However, using the following methods can make it relatively easy to desolder through-hole components and clean the pads effectively.

This article introduces a practical and effective method for quickly and cleanly desoldering through-hole components, along with circuit board design and development services.

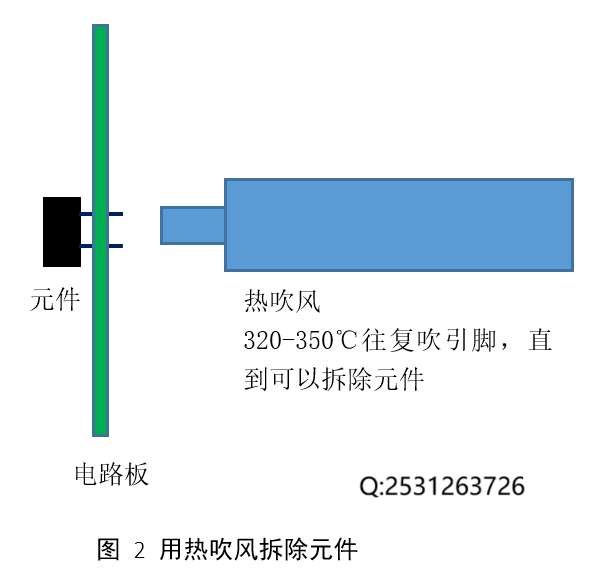

1. Desoldering through-hole components with a hot air gun

The desoldering process is quite standard. On the back of the circuit board, use a hot air gun to repeatedly blow hot air on the pins of the component at approximately 320°C-350°C until the component becomes loose, then simply pull it out.

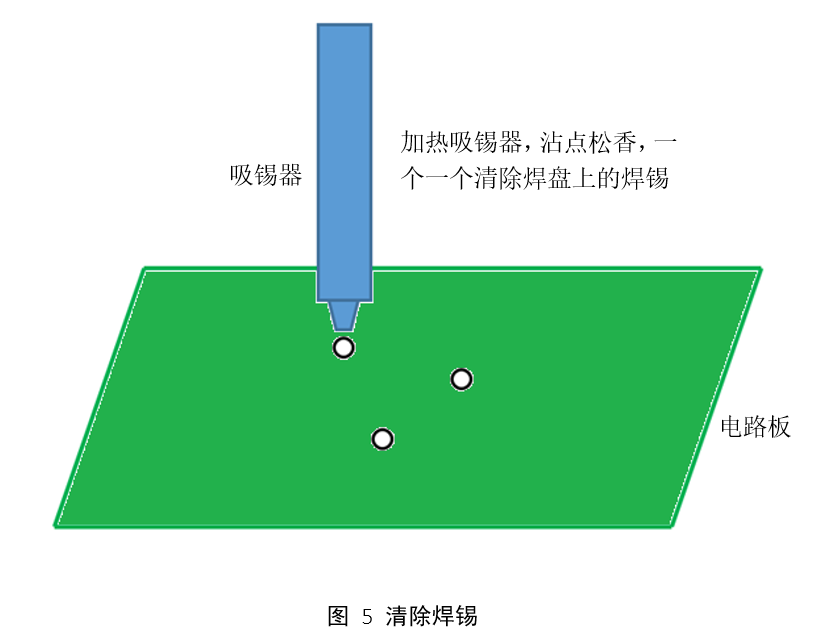

2. Using a solder sucker to remove solder from the pads

Once the component is removed, the solder holes on the pads may still be blocked with solder. What should be done? Contact us at: 25 312 263726.

At this point, a tool called a solder sucker is needed. There are several types of solder suckers:

l Electric solder sucker. It can self-heat and automatically suck solder with the press of a button.

l Spring-loaded electric solder sucker. It can self-heat, but you need to press the spring to store energy before pressing the suction button to suck solder.

l Manual solder sucker. It cannot self-heat and requires a soldering iron or hot air gun for heating. You also need to press the spring to store energy before sucking solder.

Naturally, the first type, the electric solder sucker, is the easiest to use, but it is also a bit more expensive.

The method for removing solder is to first heat the solder sucker, align it with the solder hole, melt the solder, and then suck it up. If there is not enough solder on the pad to heat it easily, you can use a bit of rosin on the solder sucker to help conduct heat to the pad, making it easier to suck up the solder.

When using the solder sucker, be sure to heat it first, align it with the pad, press the suction button, and then remove the solder sucker before releasing the button; otherwise, solder may fall back onto the circuit board.

Generally, after sucking one or two times, the pad will be quite clean.

This desoldering process has been tested and works well for removing standard through-hole components.

Shayou – Chengdu