In the wave of technological development, humanoid robots are transitioning from science fiction to reality, approaching the brink of large-scale mass production. This epoch-making technological transformation contains enormous investment opportunities, especially in the core areas of humanoid robots, such as lead screws, harmonic reducers, motors, and dexterous hands, where related listed companies are gearing up to seize important positions in the industrial chain explosion.

1. Lead Screws – The Core Precision Component for Linear Motion

As the actuator for linear motion in humanoid robots, the precision, load capacity, and service life of lead screws play a crucial role in the performance of the robots. Among them, planetary roller lead screws have become one of the core components of humanoid robots due to their unique structure and performance advantages. For example, Tesla’s humanoid robot is equipped with a total of 14 linear actuators, and if calculated at a production scale of one million units, the market size for lead screws could reach as high as 14 billion yuan..

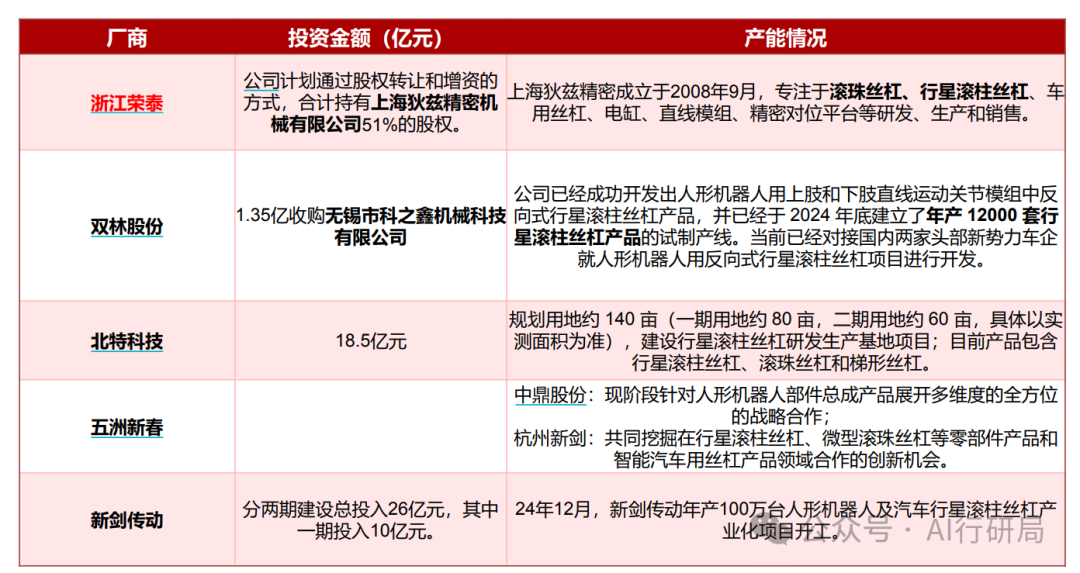

The production technology barriers for lead screws are relatively high, mainly reflected in materials, processes, and equipment. Domestic manufacturers show a significant gap compared to their overseas counterparts, but some companies have begun to catch up. The layout of listed companies is as follows:

Zhejiang Rongtai: Acquired Shanghai Diz Precision to lay out planetary roller lead screws.

Shuanglin Co., Ltd.: Successfully developed reverse planetary roller lead screw products for humanoid robot upper and lower limb linear motion joint modules, and has established a trial production line with an annual output of 12,000 sets of planetary roller lead screws by the end of 2024. Currently, they are collaborating with two leading domestic new force automotive companies on the reverse planetary roller lead screw project for humanoid robots.

Beite Technology: Planning to build a research and production base for planetary roller lead screws on approximately 140 acres; currently, their products include planetary roller lead screws, ball screws, and trapezoidal screws.

Wuzhou Xinchun: Engaged in multi-dimensional strategic cooperation with Zhongding Co., Ltd. on humanoid robot component assembly products; collaborating with Hangzhou Xinjian to explore innovative opportunities in the fields of planetary roller lead screws, micro ball screws, and screw products for intelligent vehicles.

Source: Zhejiang Merchants Securities

2. Harmonic Reducers – Key Transmission Components for Light Load Areas

Harmonic reducers are widely used in the light load areas of humanoid robots, such as the forearm, wrist, and hand, due to their advantages of small size, light weight, high transmission ratio, and high motion accuracy. Tesla’s humanoid robot has a total of 14 rotary actuators, and the market space for harmonic reducers at a production scale of one million units is approximately 14 billion yuan.

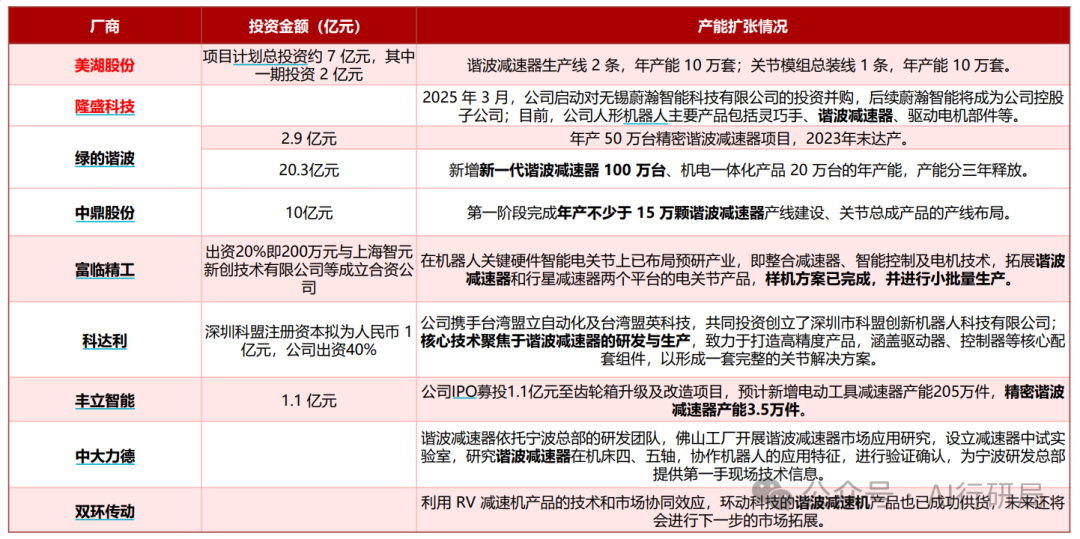

The performance of harmonic reducers is mainly affected by factors such as tooth profile design, flexible wheel materials, and process flow. There is a certain gap between domestic manufacturers and overseas manufacturers in these aspects, but companies including Meihu Co., Ltd., Longsheng Technology, Green Harmonic, and Zhongding Co., Ltd. have actively laid out in the field of harmonic reducers, enhancing competitiveness through investment mergers and capacity expansion.

Layout of listed companies:

Meihu Co., Ltd.: Invested 700 million yuan to build a harmonic reducer production line with an annual capacity of 100,000 sets.

Longsheng Technology: Initiated an investment merger with Wuxi Weihan Intelligent Technology Co., Ltd. in March 2025, after which Weihan Intelligent will become a holding subsidiary of the company; currently, the company’s main products for humanoid robots include dexterous hands, harmonic reducers, and drive motor components.

Green Harmonic: Added an annual production capacity of 1 million units of the new generation harmonic reducer and 200,000 units of mechatronic products, with capacity released over three years.

Source: Zhejiang Merchants Securities

Source: Zhejiang Merchants Securities

3. Motors – The Power Source of Robots

Motors play a crucial role in humanoid robots, with frameless torque motors (for rotary joints) and hollow cup motors (for dexterous hands) being widely used. Frameless torque motors are characterized by their small size, high power, and high torque output at low speeds, serving as the core power source for the joint actuators of Tesla’s Optimus humanoid robot, with 28 required per unit; while hollow cup motors, due to their energy-saving features, sensitive control characteristics, and stable operation, are the preferred choice for dexterous hand drive devices, requiring 34 per unit.

Zhejiang Merchants Securities estimates that at a production scale of one million robots, the market size for frameless torque motors and hollow cup motors could reach 28 billion yuan and 20.4 billion yuan, respectively. Companies such as Buke Co., Ltd., Weichuang Electric, and Hechuan Technology are actively researching and laying out in the field of frameless torque motors, while Mingzhi Electric, Dingzhi Technology, and Zhaowei Electromechanical are actively laying out in the field of hollow cup motors.

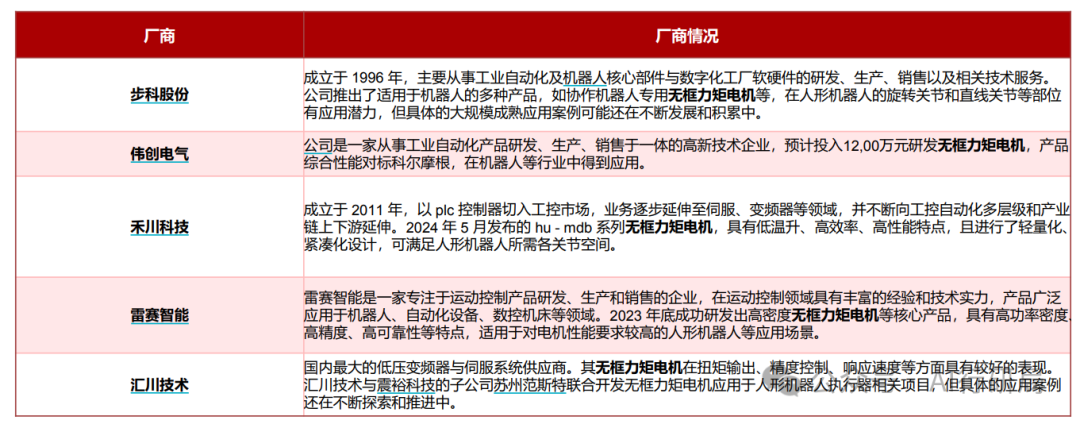

Layout of listed companies for frameless torque motors:

Buke Co., Ltd.: The company has launched various products suitable for robots, such as frameless torque motors specifically for collaborative robots, which have application potential in the rotary and linear joints of humanoid robots, but specific large-scale mature application cases may still be developing and accumulating.

Weichuang Electric: The company is a high-tech enterprise engaged in the research, production, and sales of industrial automation products, and plans to invest 12 million yuan in the research and development of frameless torque motors, with product performance benchmarks against Kollmorgen, applicable in industries such as robotics.

Hechuan Technology: The hu-mdb series frameless torque motors released in May 2024 feature low temperature rise, high efficiency, and high performance, and have undergone lightweight and compact design to meet the spatial requirements of various joints in humanoid robots.

Leisai Intelligent: Successfully developed core products such as high-density frameless torque motors by the end of 2023, characterized by high power density, high precision, and high reliability, suitable for applications requiring high motor performance, such as humanoid robots.

Source: Zhejiang Merchants Securities

Source: Zhejiang Merchants Securities

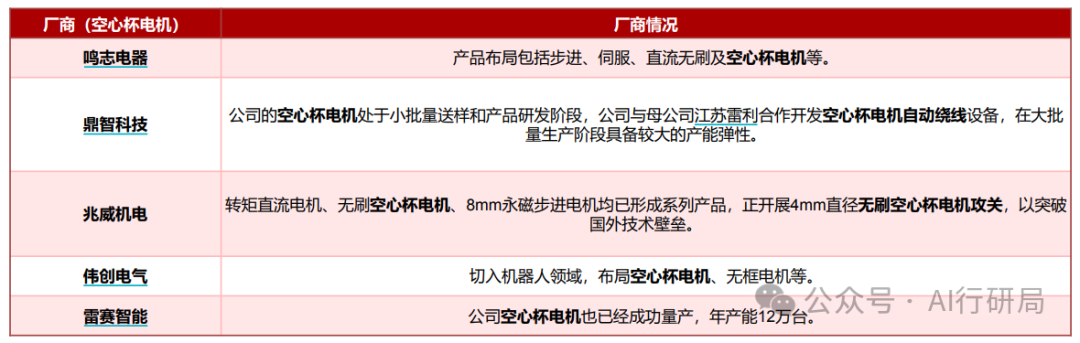

Layout of listed companies for hollow cup motors:

Zhaowei Electromechanical: Series products of torque DC motors, brushless hollow cup motors, and 8mm permanent magnet stepper motors have been formed, and they are working on a 4mm diameter brushless hollow cup motor to break through foreign technology barriers.

Dingzhi Technology: The company’s hollow cup motors are in the small batch sample delivery and product development stage, and the company is collaborating with its parent company Jiangsu Leili to develop automatic winding equipment for hollow cup motors, which has significant production capacity flexibility in the mass production stage.

Source: Zhejiang Merchants Securities

Source: Zhejiang Merchants Securities

4. Dexterous Hands – The “Nerve Endings” for Task Execution

Dexterous hands are key for executing fine operations, with the core components being the drive, transmission, and perception systems. The drive system provides power and torque for the dexterous hands; compared to traditional DC motors, the coreless hollow cup motors are small, fast in response, and highly precise, making them the preferred choice for dexterous hand drive devices.

The transmission system transmits the power from the drive system to the end effector, primarily using linkages and tendon ropes. The tendon rope transmission simulates the tendon structure of the human hand, while the wire rope transmission allows large drivers to be distanced from the actuators, reducing the load and inertia at the end, thus improving the grasping speed.

The perception system is responsible for real-time monitoring of the state of the dexterous hands. The perception system is roughly divided into internal and external categories, with internal mainly including force and torque sensors to capture joint position information and rotation angle data; external sensors include tactile sensors, etc., to detect various information about the relative position between objects and the dexterous hands.

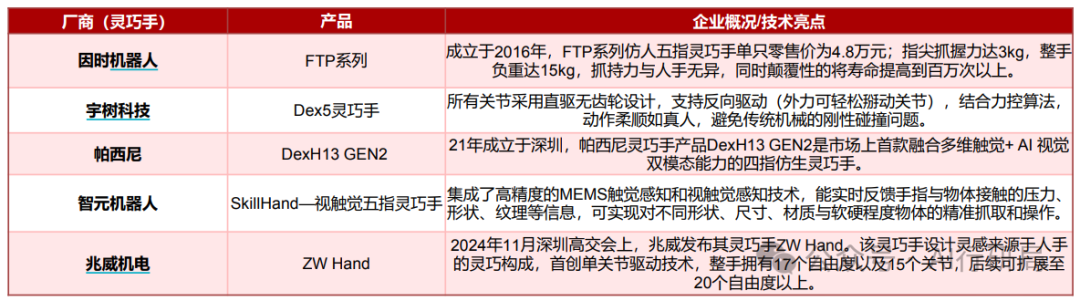

Domestic manufacturers such as Yinshi Technology, Yushu Technology, Zhiyuan Robotics, and Zhaowei Electromechanical have launched multi-degree-of-freedom bionic hands.

Dongwu Securities believes that currently, each scheme for dexterous hands has its advantages and disadvantages. Among them, the tendon rope scheme is the most human-like, and because it only has 5-6 active degrees of freedom, the cost is relatively low, but the tendon rope scheme has issues with creep and lifespan, and it is difficult to decouple at the algorithm level; currently, fully direct-drive dexterous hands have the best performance and high degrees of freedom, but because they are all active degrees of freedom, they require more than 20 motor modules, making it difficult to reduce costs in the short term and challenging to industrialize; the linkage scheme combined with lead screws can relatively balance performance and price. In the future, the dexterous hand scheme will not be a single solution, and different scenarios should have different solutions.