BMW F48 (Image source: BMW Group website)

Electronic Control Unit (ECU) certification is the future of connected vehicles—Flex and the BMW Group overcome this challenge based on Catena-X data exchange.

The Engine Control Unit (ECU), also known as DME (Digital Motor Electronics) or DDE (Digital Diesel Electronics), is a critical component in automotive manufacturing.

From emission control management to fuel injection and ignition timing, this unit ensures the functionality and performance of every vehicle.

Therefore, the automotive industry must establish robust systems to ensure that ECUs meet design specifications, safety requirements, and functional expectations before deployment in vehicles.

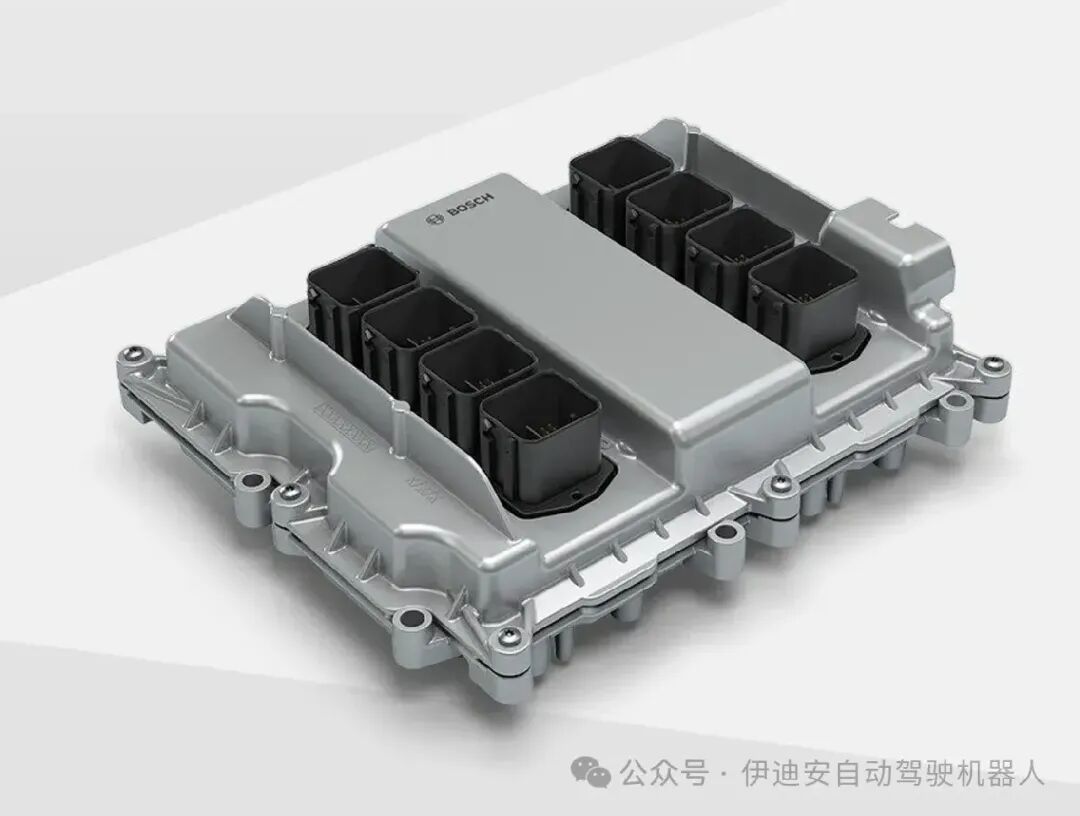

Bosch Electronic Engine Control Unit (Image source: Bosch)

The process involves rigorous testing, including Hardware-in-the-Loop (HIL), Software-in-the-Loop (SIL), and real-world environment simulations to validate the unit’s performance under various conditions.

This trend, along with the rise of functional safety standards such as ISO 26262, drives the automotive industry to adopt ECU validation to detect software bugs, hardware failures, and communication issues across a broader vehicle network.

The Value of ECU Validation

As the level of vehicle connectivity and reliance on digital systems increases, security vulnerabilities have become a significant concern.

Electronic Control Unit (ECU) certification is a key solution that enhances vehicle network security, preventing unauthorized access and protecting the safety of drivers and passengers.

Modern vehicles contain dozens of ECUs that control all functions from braking and acceleration to infotainment systems.

Without proper certification, these systems are vulnerable to cyberattacks, allowing hackers to manipulate vehicle functions, steal data, or even take control of the car remotely.

Image source: Shutterstock

Implementing ECU certification ensures that only verified and trusted software can interact with vehicle systems, thereby reducing the risk of malicious interference.

Another advantage of ECU certification is its ability to prevent the installation of counterfeit or unauthorized replacement parts.

Manufacturers can use authentication protocols to verify original components, ensuring optimal vehicle performance and safety while complying with regulatory standards.

With the rise of Over-the-Air (OTA) software updates, authentication can also prevent unauthorized firmware modifications, protecting vehicles from potential vulnerabilities.

For all these reasons, many automotive manufacturers have adopted ECU validation to ensure their vehicles can withstand evolving digital threats.

However, ECU validation is not without its challenges.

Common Barriers to ECU Validation

While ECU authentication significantly enhances vehicle security, implementing ECU authentication also presents numerous challenges for automotive manufacturers.

One of the main barriers is system complexity.

As mentioned earlier, modern vehicles contain multiple interconnected ECUs, often sourced from different suppliers.

Ensuring seamless authentication across various hardware and software platforms requires lengthy standardization and coordination among multiple stakeholders.

Another challenge is processing power and latency. ECUs must authenticate each other in real-time as well as validate external devices.

However, adding encryption authentication processes may introduce latency, affecting vehicle performance, especially in safety-critical functions such as braking or steering.

BMW is collaborating with Flex to create a streamlined ECU process (Image source: BMW Group, Pexels)

Manufacturers face the dilemma of balancing security and system efficiency when adopting ECUs.

Cost and scalability also pose challenges. Implementing robust authentication requires additional hardware, such as secure elements or cryptographic chips, which increases production costs.

Retrofitting authentication systems for older vehicles is more challenging, as older ECUs were not designed with modern cybersecurity standards in mind.

Thus, the security of Over-the-Air (OTA) updates remains a critical issue.

While authentication helps prevent unauthorized firmware modifications, attackers are continually developing new methods to bypass security measures.

Continuous updates and monitoring are necessary to address emerging threats.

Despite these challenges, ECU authentication is vital for modern vehicles.

Addressing these issues through industry-wide collaboration and technological advancements will ensure stronger and more resilient automotive cybersecurity.

What is Catena-X?

Catena-X is a collaborative data ecosystem aimed at enhancing transparency, efficiency, and security in the automotive industry supply chain.

It is the first open standardized data exchange network in the automotive industry, co-developed by leading companies such as BMW, Mercedes-Benz, Volkswagen, BASF, Bosch, SAP, Siemens, ZF, and Deutsche Telekom.

Catena-X is based on principles of security and decentralization, enabling companies to share critical data while maintaining control over their own information.

It promotes interoperability, ensuring that different systems and platforms can communicate effectively.

This data ecosystem is crucial for Flex and BMW’s ECU data exchange program, which is driving the future development of ECU certification and tracking.

“On average, thousands of ECU-related data exchanges occur daily between BMW Group and Flex,” said Anja Lang, head of Catena-X at BMW Group.

“Our collaboration with Flex enhances our capabilities, allowing us to confirm the authenticity of ECUs as they flow through the ecosystem using highly standardized and modular use case architectures.”

Flex and BMW Group ECU Data Exchange

Flex has successfully launched an Electronic Control Unit (ECU) data exchange program with BMW Group utilizing Catena-X technology.

This marks the first cross-regional collaboration between the two companies, leveraging Catena-X’s open-source peer-to-peer data space to enhance the security and efficiency of ECU authentication.

At the core of the program is Catena-X, where both companies will utilize its digital ecosystem to enable seamless, autonomous, and secure data sharing across the entire automotive value chain.

The digital infrastructure developed for ECU use cases facilitates rapid and secure authentication as components flow from Flex manufacturing bases in the Asia-Pacific, Europe, the Middle East, and Africa, to the BMW Group dealer network.

This ensures that only verified ECUs reach their intended destinations, enhancing quality control and safety.

When ECUs are completed at Flex production facilities, identification data is transmitted to BMW Group for verification.

Once confirmed accurate, the ECUs are packaged and shipped. This digital framework operates consistently across multiple sites and regions, ensuring a unified approach to ECU authentication and tracking.

“As an early member of the Catena-X collaborative ecosystem, Flex is committed to advancing this critical data exchange technology across the entire automotive value chain to enhance resilience,” said Mike Thoeny, President of Flex Automotive Business.

“We are honored to collaborate with BMW Group to achieve the first multi-regional ECU data exchange based on Catena-X, enabling seamless and secure transmission of authentication data.

Based on the success of this program, Flex is actively rolling out more Catena-X use cases.

These use cases include traceability, product carbon footprint tracking, quality management, and certificate management.

By expanding these applications, Flex aims to enhance supply chain transparency and sustainability while improving overall efficiency in the automotive industry.

Catena-X will showcase the ECU authentication use case at the Hannover Messe on March 31, 2025, in Hall 8, Booth D26.