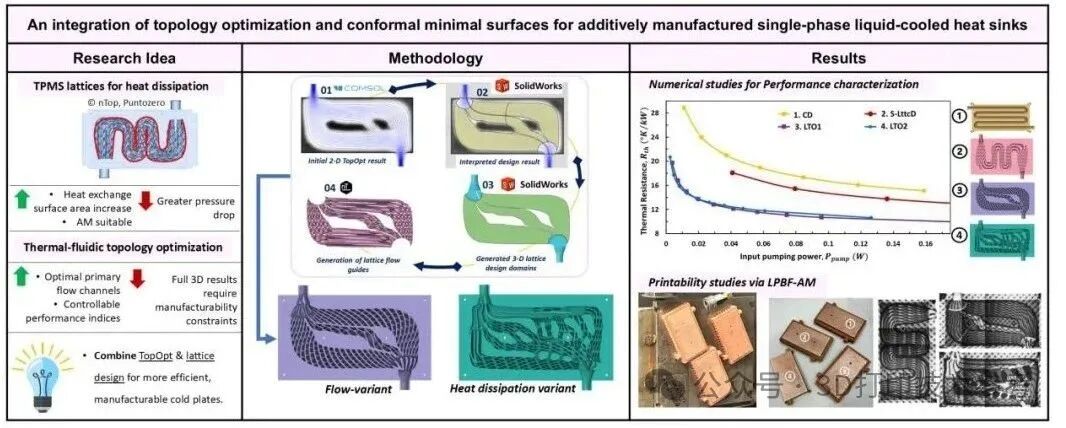

As semiconductor devices increasingly require more compact and efficient characteristics, this leads to an increase in heat generation, necessitating more effective cooling solutions. Conventional cooling methods such as jet impingement and spray cooling have complex operational issues, while microchannel heat exchangers effectively increase the heat transfer surface area but resulted in higher pressure losses and pressure drops during experimental testing. Recent joint research from the University of Waterloo, the University of Alberta, and the University of North Carolina at Charlotte has proposed a method that combines thermal fluid topology optimization with advanced lattice design techniques to design high-performance liquid cooling heat exchangers suitable for 3D printing.

The inspiration for this method comes from a liquid cooling case study using a triply periodic minimal surface (TPMS) lattice, developed by the nTop-Puntozero design team through conformal mapping. This approach focuses on replicating, adjusting, and optimizing the original design while enhancing flow characteristics and adhering to 3D printing design guidelines and constraints. The study evaluated four design variants: traditional serpentine cold plate CD, improved serpentine design S-LttcD, and two hybrid TopOpt lattice heat exchangers. Numerical simulations were also conducted during the study to characterize performance metrics under a range of liquid pumping powers.

The inspiration for this method comes from a liquid cooling case study using a triply periodic minimal surface (TPMS) lattice, developed by the nTop-Puntozero design team through conformal mapping. This approach focuses on replicating, adjusting, and optimizing the original design while enhancing flow characteristics and adhering to 3D printing design guidelines and constraints. The study evaluated four design variants: traditional serpentine cold plate CD, improved serpentine design S-LttcD, and two hybrid TopOpt lattice heat exchangers. Numerical simulations were also conducted during the study to characterize performance metrics under a range of liquid pumping powers.

The study designed four planar single-liquid heat exchangers to verify the performance of the heat exchangers produced by the proposed method, reflecting key conceptual routes of traditional and innovative cooling solutions. The simple serpentine design CD is inspired by conventional cold plate solutions from mainstream manufacturers. S-LttcD is an improved serpentine design with larger main flow channels to allow for conformal specification of diamond-like surface lattices through method II. LT01 and LT02 are the results of the proposed method, utilizing a diamond TPMS lattice that aligns with the identified flow channels.

The study designed four planar single-liquid heat exchangers to verify the performance of the heat exchangers produced by the proposed method, reflecting key conceptual routes of traditional and innovative cooling solutions. The simple serpentine design CD is inspired by conventional cold plate solutions from mainstream manufacturers. S-LttcD is an improved serpentine design with larger main flow channels to allow for conformal specification of diamond-like surface lattices through method II. LT01 and LT02 are the results of the proposed method, utilizing a diamond TPMS lattice that aligns with the identified flow channels.

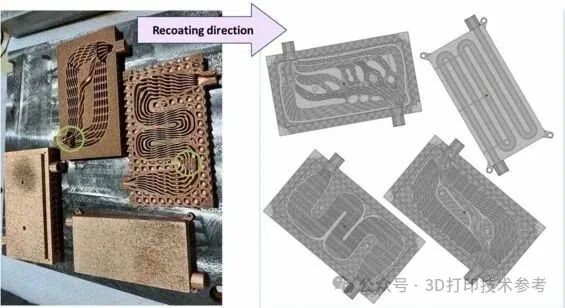

3D printing can easily manufacture highly complex features with extremely high resolution (100 μm), thus gaining significant applications in aerospace, medical, and automotive industries, where the development of cooling technologies (heat exchangers and radiators) is considered one of the forefront applications of this technology. Some non-traditional cooling systems, including finned serpentine microchannels and increasingly grid-based cold plates, have also become the subject of extensive research, where 3D printing can design heat exchangers with degrees of freedom and various algorithm-driven designs, particularly through topology-optimized heat exchangers.Overall, this study proposes a new method that combines thermal fluid topology optimization with advanced conformal lattice technology, establishing a framework for enhancing liquid cooling heat exchangers. The method proposed in this study significantly improves mechanical performance compared to traditional designs, and the hybrid design approach achieves good flow distribution, reduces pressure drop and thermal resistance, narrows the gap with manufacturability, addresses the shortcomings of traditional heat exchanger design methods, enhances the performance of liquid cooling heat exchangers, and is suitable for 3D printing, demonstrating multidisciplinary innovative potential.Note:This article is created by 3D Printing Technology Reference and is not authorized for reproduction without contact..Reposting is welcome

3D printing can easily manufacture highly complex features with extremely high resolution (100 μm), thus gaining significant applications in aerospace, medical, and automotive industries, where the development of cooling technologies (heat exchangers and radiators) is considered one of the forefront applications of this technology. Some non-traditional cooling systems, including finned serpentine microchannels and increasingly grid-based cold plates, have also become the subject of extensive research, where 3D printing can design heat exchangers with degrees of freedom and various algorithm-driven designs, particularly through topology-optimized heat exchangers.Overall, this study proposes a new method that combines thermal fluid topology optimization with advanced conformal lattice technology, establishing a framework for enhancing liquid cooling heat exchangers. The method proposed in this study significantly improves mechanical performance compared to traditional designs, and the hybrid design approach achieves good flow distribution, reduces pressure drop and thermal resistance, narrows the gap with manufacturability, addresses the shortcomings of traditional heat exchanger design methods, enhances the performance of liquid cooling heat exchangers, and is suitable for 3D printing, demonstrating multidisciplinary innovative potential.Note:This article is created by 3D Printing Technology Reference and is not authorized for reproduction without contact..Reposting is welcome

Industry expert communication groupQ group:248112776

Further reading:

1. Oerlikon showcases high-performance components for aerospace and defense at the Paris Air Show

2. SanDi Technology successfully wins the bid for FAW’s casting automation transformation project

3. Thermodynamic simulation of metal 3D printed lattice structures, how to achieve both speed and accuracy?

4. Ming-Chi Kuo: Apple’s foldable iPhone may start production this fall