Skip to content

Research Background

- Limitations of ConcreteOrdinary concrete is prone to cracking and has poor ductility; traditional reinforced concrete faces issues such as insufficient bonding with the matrix and limited freedom of shape.

- Potential of Steel Fiber ConcreteSteel fibers can enhance the crack resistance of concrete, but randomly distributed fibers cannot fully exert their reinforcing effect.

- Shortcomings of Existing Fiber Orientation TechnologiesMethods such as vibration and special pouring equipment struggle to accurately control fiber orientation, while magnetic field orientation technology has primarily been applied to traditional formwork concrete pouring and has not yet been validated for feasibility in 3D printed concrete.

- InnovationProposesin-situ magnetization technology, which uses a permanent magnet nozzle to real-time orient steel fibers during the 3D printing process, addressing the randomness of fiber distribution in the printing process.

Research Methodology

- Magnetic Field Design

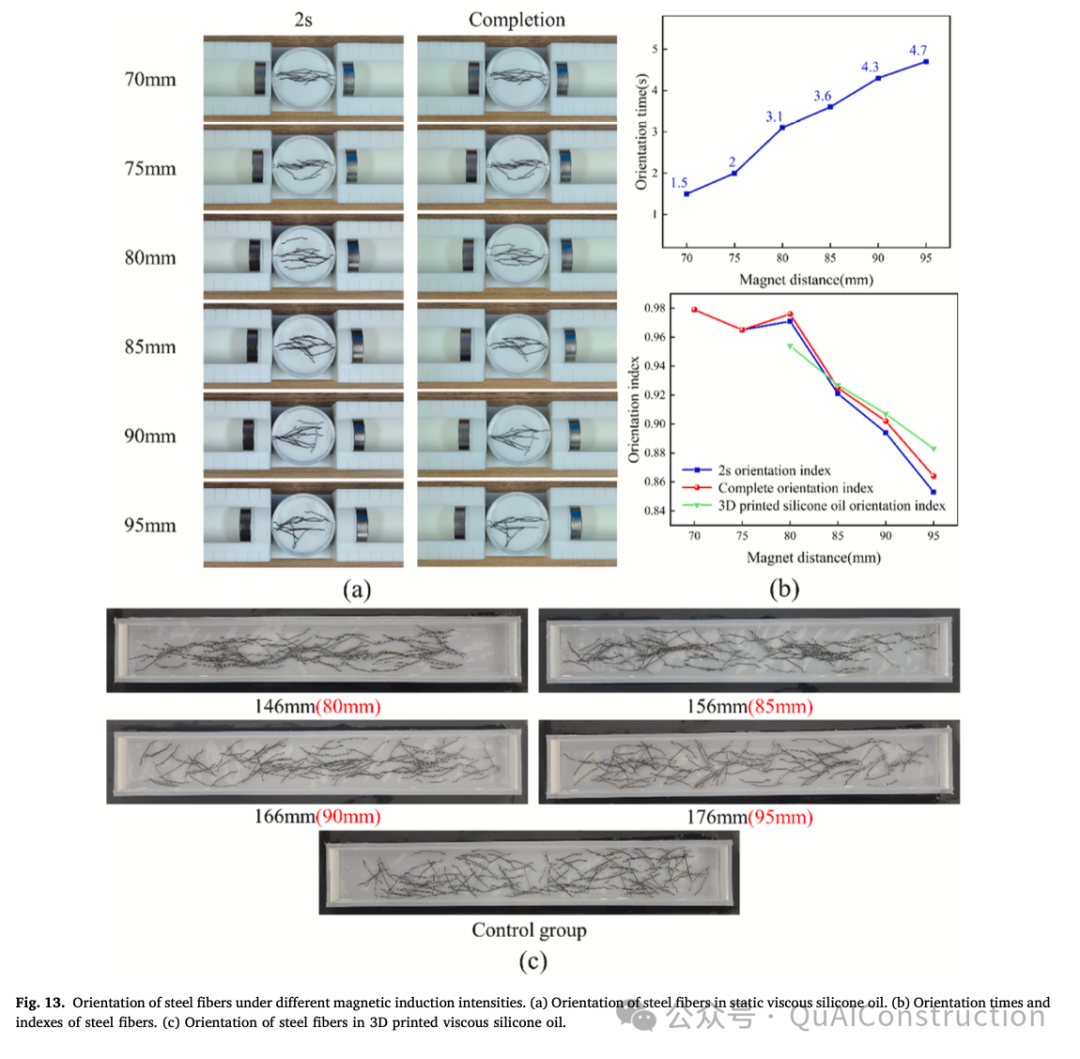

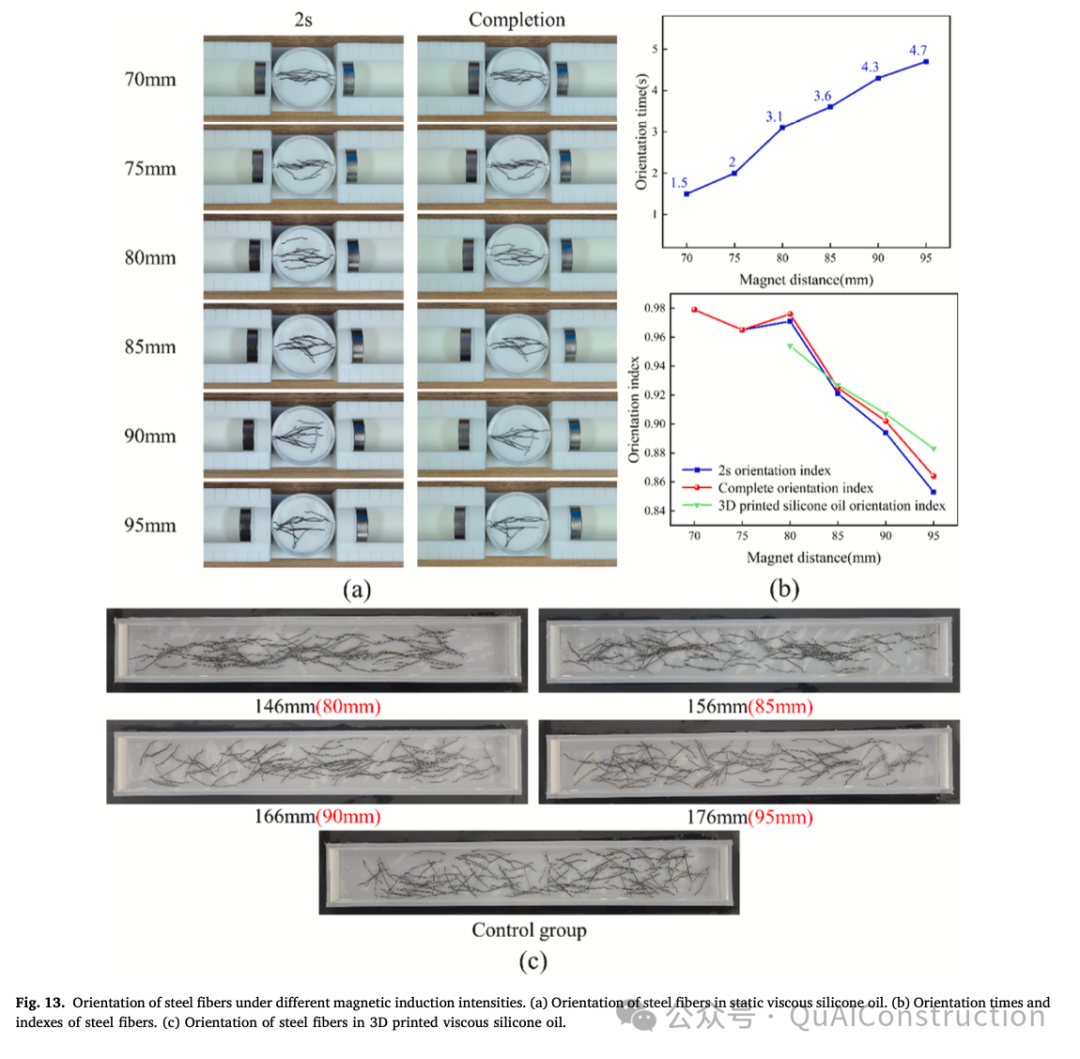

- Developed apermanent magnet nozzle with magnetic shielding function (including N52 permanent magnets and DT4 magnetic shielding plates), controlling the magnetic induction strength at the nozzle center (20–50 mT) by adjusting the pole spacing (70–95 mm).

- Theoretical model analyzes the mechanisms of magnetic torque (Tm) and magnetic force (Fm) acting on steel fibers (Formulas 1-8).

Equivalent Simulation Experiments

- Usedtransparent silicone oil (viscosity 10,000 CST) to simulate the rheological properties of concrete, qualitatively observing the effect of the magnetic field on fiber orientation.

Materials and Printing Process

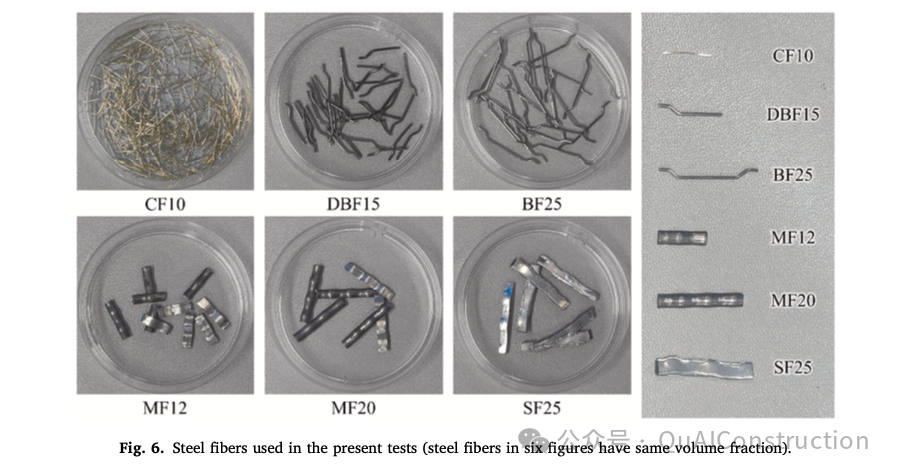

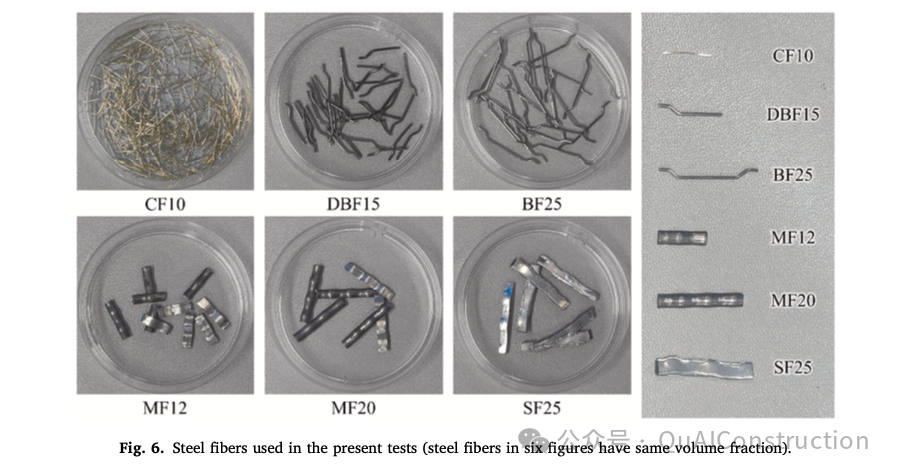

- Concrete MixPO52.5 cement + R.SAC42.5 sulfoaluminate cement + quartz sand + six types of steel fibers (length 10–25 mm, volume fraction 0–0.75%).

- 3D Printing ParametersLayer thickness 20 mm, printing speed 21 mm/s, nozzle diameter 40 mm.

Characterization and Testing

- Fiber Orientation EvaluationX-ray micro-imaging (Zeiss Xradia 610) measures the fiber orientation angle θ and calculates the orientation index δ (Formula 9).

- Mechanical PropertiesTestingcompressive strength (40 mm cubes) andbending strength (40×40×160 mm prisms), comparing X/Y/Z triaxial loading results.

Research Results

- Impact of Magnetic Field Strength

- Optimal Magnetic Induction Strength: At a nozzle center magnetic induction of34 mT (pole spacing 80 mm), the orientation index of BF25 fibers is highest (δ≈0.85), with compressive/bending strength increased by over 50%.

- Excessive magnetic strength (>34 mT) leads to fiber adhesion to the nozzle wall, blocking the flow path and reducing mechanical properties.

- Impact of Fiber Volume Fraction

- Optimal Volume Fraction 0.5%BF25 fibers achieve a compressive strength of 48.2 MPa (Z-direction) and a bending strength of 8.3 MPa (Z’ direction).

- Exceeding 0.75% leads to fiber agglomeration, blocking the nozzle and reducing strength.

Impact of Fiber Type

- BF25 (25 mm bow-shaped fibers) and SF25 (25 mm shear fibers) are the most effective due to their high aspect ratio and stiffness, effectively bridging cracks.

- Short fibers (e.g., CF10) are easily bent, providing weak reinforcement; milled fibers (MF) tend to form voids due to their bent structure, resulting in limited strength enhancement.

- Verification of Orientation Mechanism

- Reliability of Silicone Oil Simulationis consistent with the fiber orientation trend in concrete (error <10%), but concrete has greater resistance due to its non-Newtonian fluid characteristics.

- 3D Printing Self-Orientation EffectEven without a magnetic field, fibers are partially oriented along the printing direction (δ=0.767).

Conclusion

- Feasibility of Magnetic Field OrientationThe permanent magnet nozzle can achieve the oriented arrangement of steel fibers in 3D printing, with optimal parameters beingmagnetic induction strength 34 mT + BF25 fiber volume fraction 0.5%.

- Mechanism of Performance Enhancement

- Oriented fibers are perpendicular to the crack direction, significantly enhancing crack bridging capability.

- The magnetic field promotes fiber dispersion, enhancing inter-layer bonding strength and improving anisotropy.

Industrial PotentialThis technology can expand the application of 3D printed concrete in complex structures, reducing reliance on steel reinforcement and enhancing mechanical reliability.