Ceramic House Facade

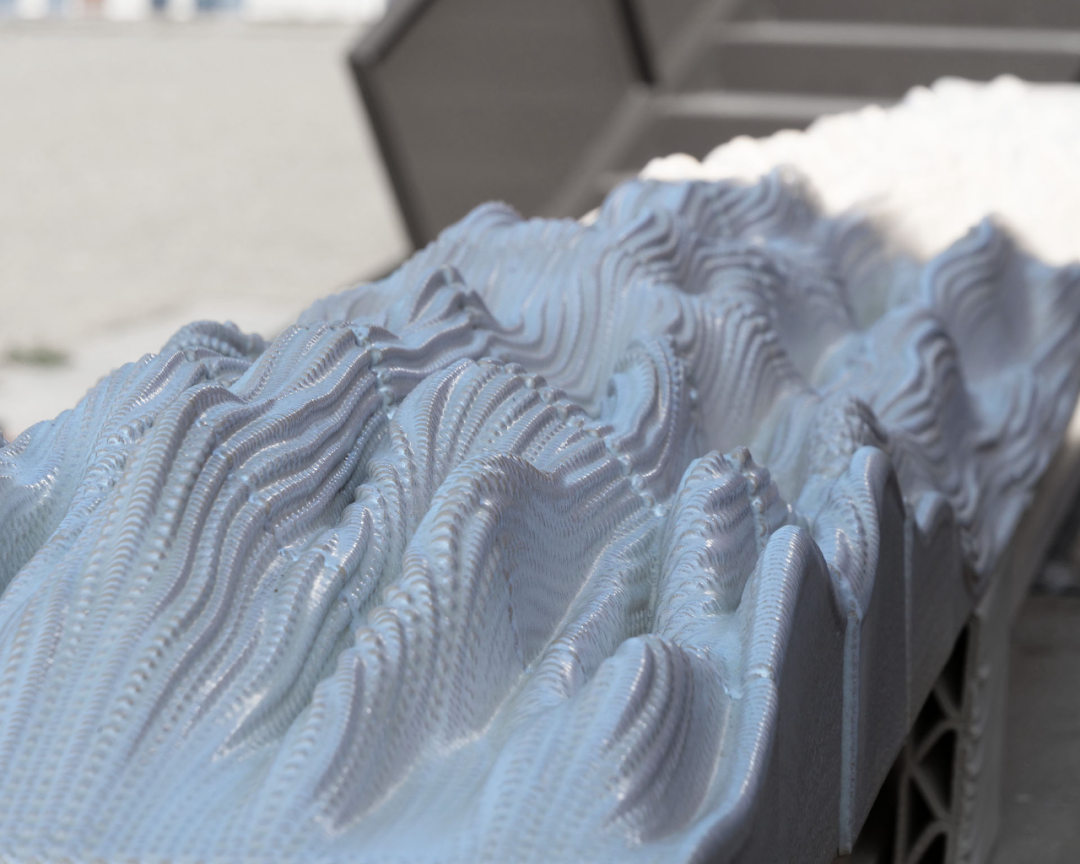

3D Printed Tiles

In modern architectural design, 3D printing technology has become quite common, but the quality of typical printed products is often rough, making it difficult to create exquisite facades.

However, the project named Ceramic House successfully utilizes 3D printing technology to create a refined decorative effect.

Ceramic House is located on the shopping street PC Hooftstraat in Amsterdam, Netherlands. The designer used 3D printed tiles to form the facade, which not only has a visual impact but also highlights the architect’s core role in the architectural design and implementation process.

# Facade Design #

The facade was designed by the Rotterdam architectural firm Studio RAP, featuring a two-tone color scheme of white below and red above. The lower half consists of white tiles, while the upper half is made of red bricks. This color choice aims to harmonize the building with its surrounding neighborhood.

The facade design echoes the original red and white tiles of the historic district▽

sdfd

The entire facade is divided into several areas, each with different tile shapes and textures.

These differently shaped tiles interlock to create a very interesting and layered facade.

# White Tiles #

The lower half of the facade features white tiles with a pearl white glaze and a subtle yellow shadow.

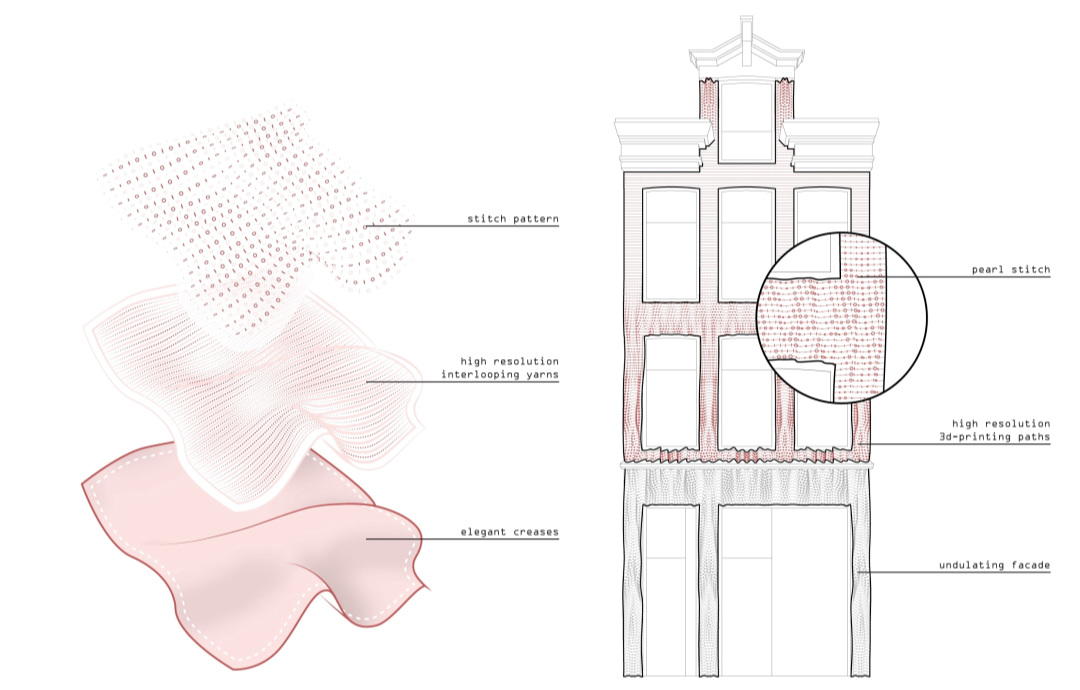

These tiles have only slight undulations at the base, but as the height increases, they become more three-dimensional and expressive, presenting a knitted texture visual effect.

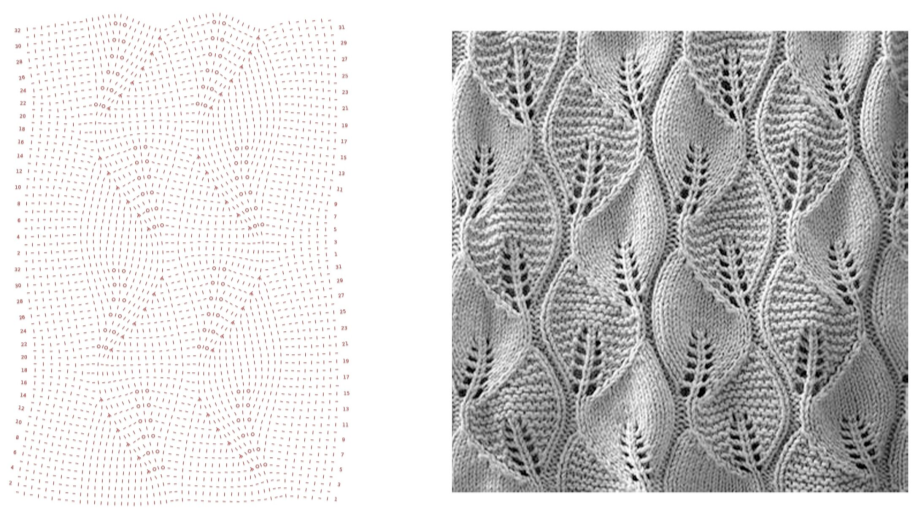

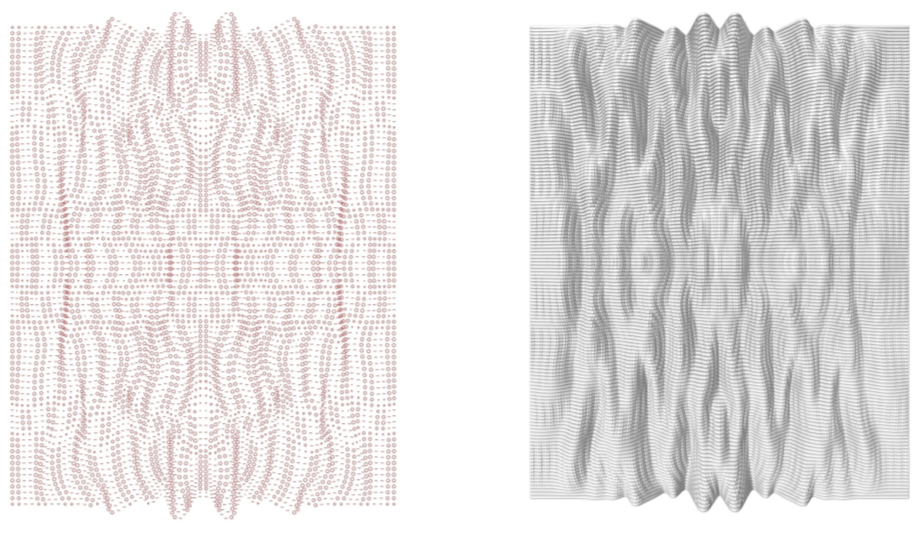

This design inspiration comes from the texture of knitted sweaters and is realized through digital algorithms using 3D printing to achieve a unique decorative effect.

This design inspiration comes from the texture of knitted sweaters and is realized through digital algorithms using 3D printing to achieve a unique decorative effect.

Design inspiration and digital design presentation▽

# Red Tiles #

The upper part of the building consists of red bricks, which are coated with three different shades of red glaze.

The tiles come in various shapes, mostly rectangular or square, presenting an abstract and modern character. Their scale, size, type, and color are synchronized with the adjacent buildings, creating a sense of harmony with the surrounding environment.

The installation method of the red tiles is also innovative; these tiles are adhered to laser-cut stainless steel boxes, interspersed with the original masonry.

sdfd

The stainless steel window boxes not only provide support for the facade but also integrate into the facade decoration. These boxes are made from laser-cut stainless steel plates, featuring precise dimensions and shapes that correspond with the tile designs.

Installation photos▽

# 3D Tiles #

At the beginning of the design, the designer reinterpreted the decorative quality and design of the glazed ceramics of the historic city of Amsterdam.

△Facade tile design drawing During the digital modeling process, the designer considered the facade’s outline and site characteristics, ensuring that the new facade harmonized with the surrounding buildings before commencing production.

△Facade pattern design drawingBased on the digital model, the designer used ceramic 3D printing technology to produce the tiles. This technology employs special 3D printers and ceramic materials, building up layers of material to create high-precision and complex geometric shapes, giving each tile a unique texture and form.

Process animation▽

The tiles measure approximately 40 x 20 centimeters.

The finished tiles are placed in a well-ventilated area to dry, a process that typically takes several days. During the drying period, the tiles need to be regularly turned to ensure even drying. Once the tiles are completely dry, they can undergo sintering and glazing treatment.

Large tiles serve as the lower facade, while smaller bricks are used for the upper facade.

Large tiles serve as the lower facade, while smaller bricks are used for the upper facade.

The firing and glazing process is completed at Royal Tichelaar, one of the oldest porcelain manufacturers in the Netherlands.

First, the tiles are fired to make them hard and durable, then a glaze is applied to the tiles, which is a special material that alters the color and appearance of the tiles while protecting their surface from damage and contamination.

Finally, the 3D printed tiles are transported to the site for installation, where they must be arranged in a specific order and manner to create the final facade effect.

Of course, on PC Hooftstraat, besides the Ceramic House, the facades of other shops are also very attractive.

For example, the LV flagship store at PC Hooftstraat 140-142, designed by the architectural firm UNStudio, and the adjacent flagship store of a fashion brand at PC Hooftstraat 138.

The new LV store surprisingly does not follow the luxury trend, using stainless steel bricks for the exterior, which is quite understated!

Additionally, the Chanel flagship store in Amsterdam, designed by the architectural firm MVRDV▽

Stepping on LV and PRADA, it only uses a glass brick, this design is really cool!

//Design New Media Matrix Together Set us as “Starred★” to receive notifications first▼Design Official Website Together

Set us as “Starred★” to receive notifications first▼Design Official Website Together

Like it

Click to view