As a global leader in shipbuilding, China has maintained its position at the top of three major indicators for several consecutive years. However, the traditional shipbuilding model in our country is facing bottlenecks such as material waste and processing limitations. Consequently, 3D printing technology, which can break through the constraints of traditional shipbuilding methods, is gradually coming into the spotlight. 3D printing is a manufacturing method that constructs objects from the ground up through material accumulation. With recent breakthroughs in technology and materials, 3D printing has become a powerful tool for advanced manufacturing, offering vast market application potential and significant implications for hull structure construction, part replacement, and safe operation. The International Association of Classification Societies (IACS) will release the Rec.186 standard in 2025, which will greatly promote the application of 3D printing technology in shipbuilding.

01Issues with Traditional Shipbuilding Methods

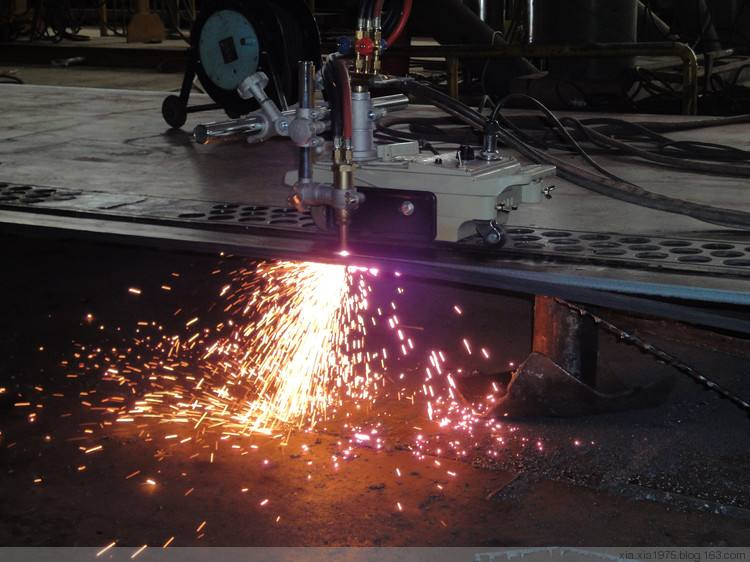

The traditional shipbuilding method is a “subtractive manufacturing” process that involves cutting and machining, resulting in significant raw material waste. Currently, shipbuilding is evolving towards mechanization, with assembly lines improving production efficiency for hull manufacturing. However, the design and processing of complex structural components are still limited by machining equipment, requiring substantial manual labor for assembly, which greatly reduces manufacturing efficiency. The construction and assembly of critical sections primarily rely on welding and lifting processes, which are time-consuming, labor-intensive, and pose certain risks. Additionally, some confined areas are extremely difficult to process due to equipment and manpower limitations. The use of welding processes inevitably leads to issues such as welding distortion, and to address these derivative problems, processes like water and fire bending and cold bending are required to shape components, but the accuracy of shaping depends on manual skill, making precise control impossible.

02

Advantages of 3D Printing Technology in Shipbuilding

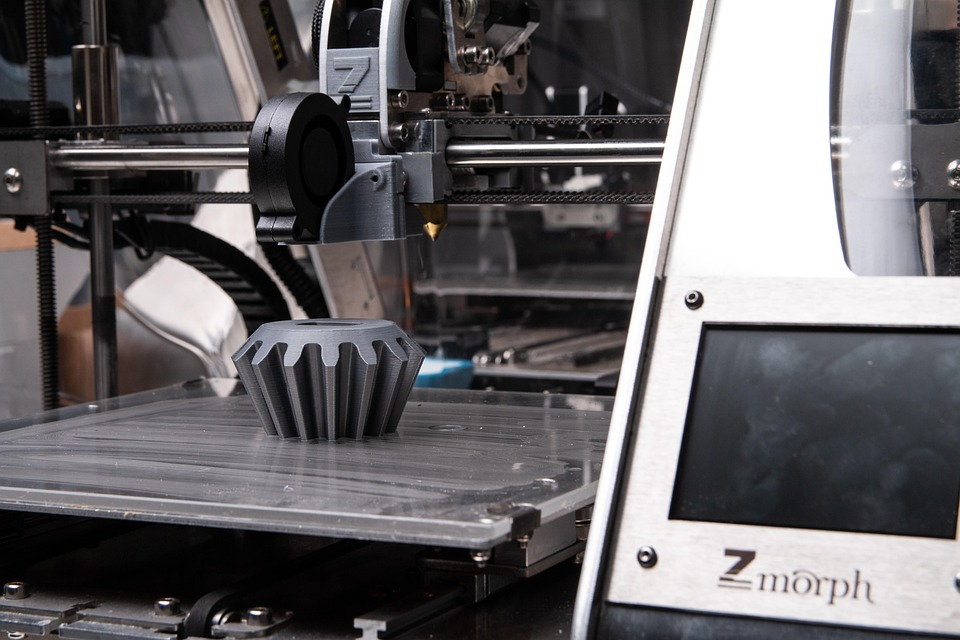

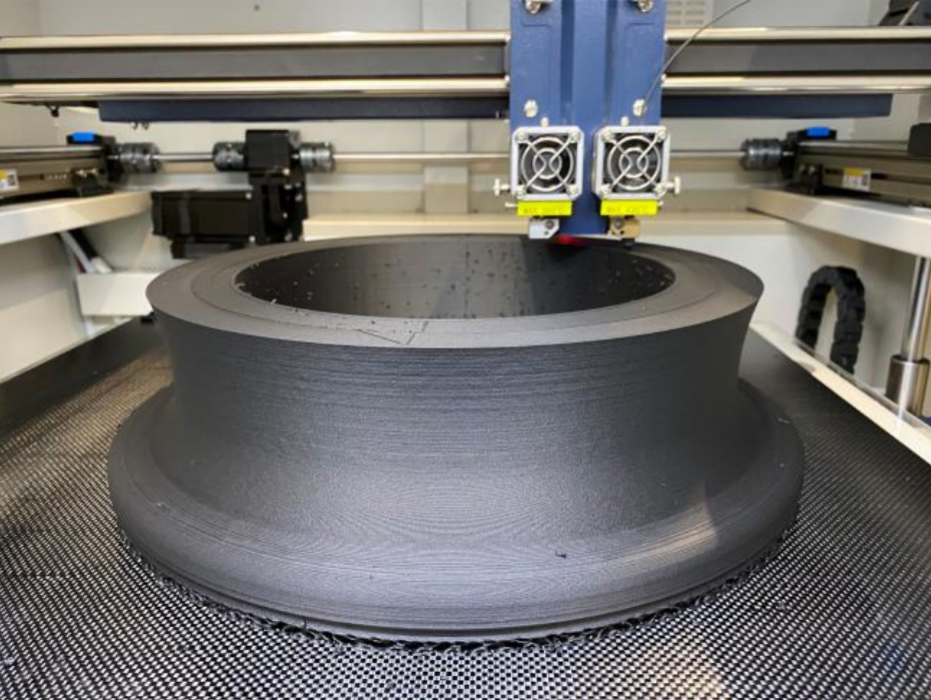

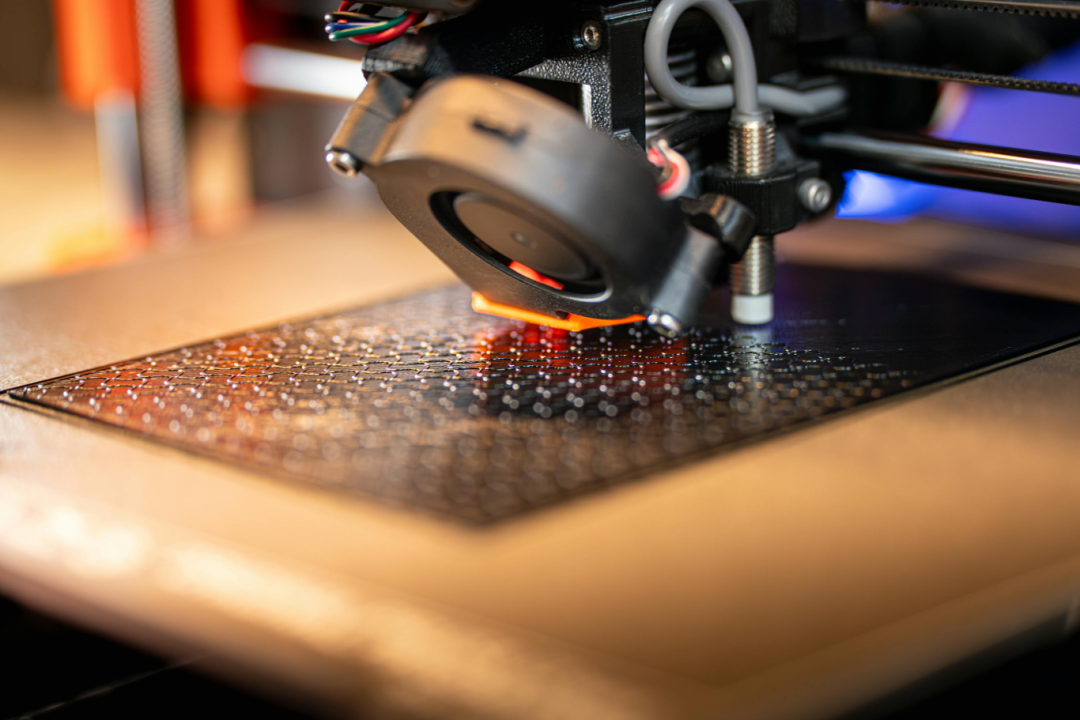

3D printing technology is a rapid prototyping technology that constructs objects based on digital models using powder-based metals or plastics and other adhesive materials through layer-by-layer printing. Compared to traditional shipbuilding methods, the advantages of 3D printing technology for hull construction are primarily reflected in the following aspects:

Efficient Material Utilization: By manufacturing hulls through layer-by-layer material accumulation, only the necessary amount of material is used, avoiding the 30%-60% material waste typical in traditional subtractive manufacturing processes like cutting and milling, significantly reducing resource consumption.

Flexible Design and Manufacturing: Its integrated forming method can overturn the segmentation, assembly sequence, and component design concepts in traditional shipbuilding processes, allowing complex geometries that are difficult to achieve with traditional techniques to be easily completed through 3D printing. Designs that were previously constrained by the limited space of ship compartments can also become a reality with the support of 3D printing technology.

Efficient Production and Maintenance: With 3D printers equipped on ships or at ports, the time for manufacturing spare parts can be reduced from months to days, or even printed on-site instantly, greatly reducing inventory and logistics costs. The component design verification cycle is significantly shortened, lowering the costs of testing and improving hull components, and enhancing the efficiency of hull design optimization. Traditional ships require carrying a large number of spare parts, while 3D printing technology can produce parts on demand through digital models, reducing inventory pressure and logistics costs, and lowering ship maintenance costs.

03

Challenges Facing Hull 3D Printing Technology

As an innovative application of additive manufacturing in the shipbuilding field, hull 3D printing technology has various mainstream forming methods that differ based on material type, structural requirements, and manufacturing scale. The main methods include Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Wire Arc Additive Manufacturing (WAAM), Stereolithography (SLA), Multi Jet Fusion (MJF), and Continuous Fiber Manufacturing (CFM). The mainstream technologies for hull 3D printing focus on FDM, SLS, and WAAM, covering plastic, metal, and ultra-large structural needs. FDM is suitable for rapid prototyping and environmentally friendly manufacturing, while SLS and WAAM meet high-performance and large-scale production requirements, and SLA and CFM focus on precision and composite material applications.

|

Forming Method |

Applicable Materials |

Precision |

Speed |

Cost |

Typical Applications |

|

FDM |

Thermoplastics, Composites |

Medium-Low |

Slow |

Low |

Small to Medium Hulls, Spare Parts |

|

SLS |

Metals, Nylon |

Medium-High |

Medium |

High |

Engine Parts, Load-Bearing Structures |

|

WAAM |

Metal Wires |

Low |

Fast |

Medium |

Large Hulls, Floating Platforms |

|

SLA |

Photosensitive Resins |

High |

Medium |

High |

Ship Models, Precision Parts |

|

CFM |

Fiber Composites |

Medium-High |

Medium |

Very High |

High-Performance Sailboats, Unmanned Vessels |

Different forming methods use various raw materials, processing equipment, application ranges, and environmental conditions required during processing. There are specific requirements for the environmental conditions of ships and the storage conditions of raw materials. Moreover, existing forming methods still face challenges such as low forming precision leading to rough surfaces, slow printing speeds, and limited material strength and corrosion resistance, making it difficult to adapt to large hull manufacturing. Some forming methods also generate dust and toxic gases during the forming process, posing significant challenges for the application of 3D printing technology on ships. Previously, the industry lacked mature and unified technical standards for managing 3D printing technology, and there was a lack of regulatory measures for inspecting and supervising ships built using 3D printing technology.

04

Release of Recommended Standards for 3D Printing Technology

On March 24, 2025, the International Association of Classification Societies (IACS) released an important recommended standard—Rec.186, providing a standardized framework for the application of 3D printing technology in maritime and offshore fields.

The standard indicates that the advantages of 3D printing technology are primarily concentrated in the following aspects: design freedom, enabling the manufacture of complex structures that traditional processes cannot achieve (such as internal flow channels and lattice structures), supporting topology optimization and algorithm-generated designs, and allowing geometric shapes to be constructed directly from CAD models or digital files, reducing assembly requirements; high material utilization, with powder recovery rates typically exceeding 95%, reducing material waste, and supporting multi-material mixed printing such as metal-ceramic composite structures; easy realization of rapid response and small-batch production, suitable for customized part manufacturing, shortening R&D cycles, and allowing direct repair of damaged parts through 3D printing, reducing downtime; promoting material lightweighting and performance optimization, achieving weight reduction through structural optimization and adjusting the chemical composition of materials to enhance corrosion resistance, high-temperature resistance, and other special properties.

Rec.186 specifies clear requirements for material control, process specifications and monitoring, inspection and certification, as well as production and traceability management. It sets explicit requirements for powder particle size distribution, flowability, and sphericity, and requires that the printing wire clearly defines chemical composition, mechanical properties, and surface roughness, limiting the number of times recycled powder can be used to avoid cross-contamination. Key materials such as titanium alloys and nickel-based superalloys must undergo chemical analysis and microstructure testing. Each batch of powder must provide documentation including batch numbers, supplier information, and inspection reports for traceability.

Rec.186 details specific technical guidance for three main 3D printing methods: Powder Bed Fusion (PBF), Directed Energy Deposition (DED), and Binder Jetting (BJT). For each method, the document defines process parameters and inspection protocols to ensure consistent quality of produced parts. Additionally, the recommendation introduces a three-tier testing system, categorizing components based on their criticality of application into AM 1 to AM 3 levels. For example, safety-critical components used in propulsion systems or structural components require more stringent certification procedures. Rec.186 stipulates that raw materials (including metal powders, wires, and binders) must comply with strict quality control measures. To ensure supply chain transparency, Rec.186 adds provisions for recycling protocols and material traceability to prevent defects caused by raw material issues, enhancing the reliability of the production process. Rec.186 emphasizes topology optimization, simulation-based pre-build verification, and performance verification during the design certification phase. In the post-processing stage, Rec.186 pays special attention to non-destructive testing (NDT) procedures suitable for the unique material characteristics of additive manufacturing components. For instance, it recommends using computed tomography (CT) scanning to detect internal defects such as porosity or incomplete fusion. These defects may affect the integrity of components under mechanical stress or corrosion exposure, thus requiring assessment through calibrated testing methods, considering the anisotropic behavior common in layered manufacturing.

Rec.186 clearly establishes the standards applicable to 3D printing technology for ships and marine engineering, covering mainstream processes such as Powder Bed Fusion (PBF), Directed Energy Deposition (DED), and Binder Jetting (BJT), and defines process parameters, inspection processes, and certification requirements. By clarifying standardized processes and quality control requirements (such as powder recycling protocols and non-destructive testing techniques), it provides a basis for the reliable production of complex components, promoting their transition from experimental stages to industrial applications.

The release of IACS Rec.186 marks the transition of 3D printing technology in the maritime field from the exploratory phase to the era of standardized application.

Conclusion

Although hull 3D printing technology still faces challenges in material performance validation, large-scale manufacturing precision, manufacturing equipment costs, data conversion efficiency, and the lack of industry standards, its advantages in efficient material utilization, complex structure manufacturing, and rapid response capabilities will undoubtedly drive the shipbuilding industry towards lightweight, customized, and sustainable transformations, aligning more closely with the overall development trend of green and intelligent shipping. The gradual unification of technical standards for 3D printing technology will accelerate the green and intelligent transformation and global supply chain integration, injecting new momentum into the high-quality development of the shipping industry.

The images above are sourced from the internet, and the article represents the author’s personal views.

Contributed by | Du Weichen

Edited by | Liu Yufei

Reviewed by | Shen Jiaqiang, Dong Yiyi, Li Donglin