PCBA (Printed Circuit Board Assembly) is a core aspect of modern electronic manufacturing, and its quality directly affects the performance and reliability of the final product. In the PCBA production process, the pre-production review is a crucial preparatory work that not only relates to whether the product design and manufacturing meet the requirements but also directly impacts production efficiency and product quality. Taking Hengtianyi’s PCBA services as an example, the content of the pre-production review covers multiple aspects, including process document review, circuit board design, fixture design, and Bill of Materials (BOM) review, ensuring that every link from design to production meets high standards.

Key Elements of PCBA Pre-Production Review and Hengtianyi’s Standardized Practices

1.Content of PCBA Pre-Production Review

Process Document Review

The process documents are guiding documents in the PCBA manufacturing process, including process flow, process parameters, and process standards.

During the pre-production review, these documents need to be thoroughly reviewed to ensure they are complete, reasonable, scientific, and comply with national or industry standards. For example, Hengtianyi checks whether the process flow meets the product manufacturing requirements, whether there are any skipped or repeated steps, and ensures that the process parameters are accurate and scientific to guarantee product quality.

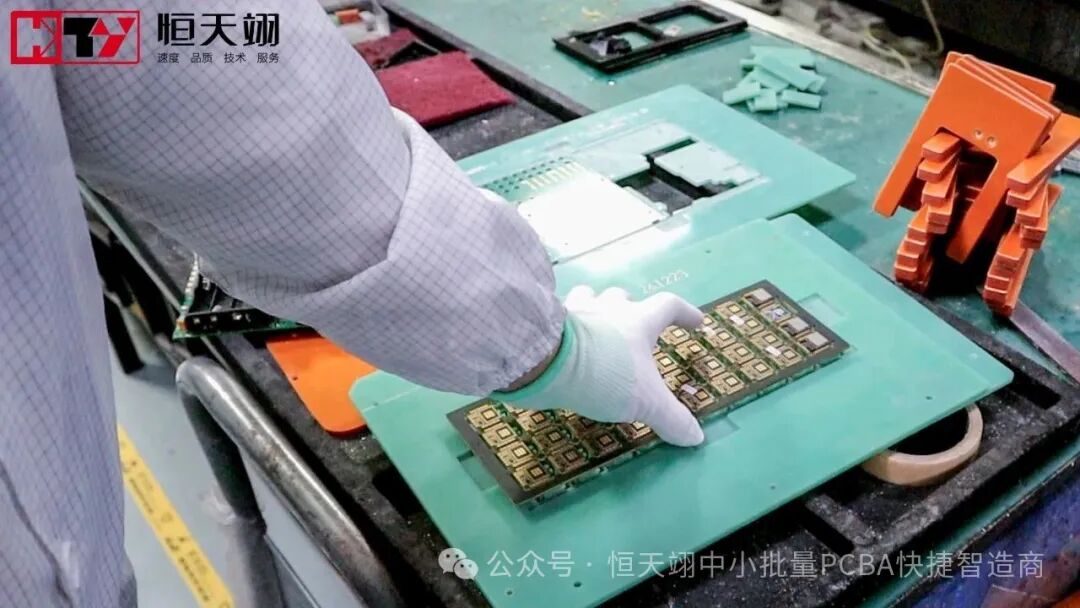

Circuit Board and Prototype Review

The design of the circuit board is the foundation of PCBA manufacturing. During the review process, it is necessary to ensure that the circuit board design is defect-free, the arrangement of components is reasonable, the pad layout meets soldering requirements, and the direction of the lines is correct. Additionally, the prototype needs to be checked to ensure its feasibility in actual production.

Fixture Design Review

The rationality of fixture design directly affects the assembly quality and efficiency of PCBA.

During the review process, it is necessary to assess whether the fixture design meets the product manufacturing and usage requirements, and whether the material selection and processing technology are reasonable.

Bill of Materials (BOM) Review

The BOM is an important basis for PCBA production, listing all the components needed along with their specifications, quantities, and packaging information.

During the review, it is necessary to check the BOM list in advance, optimize material descriptions, verify models, packaging, quantities, positions, and improve brand specifications and part number information.

External Processing Assessment

If certain components of the PCBA need to be outsourced for production, the review process must also assess the capabilities and quality of the outsourcing vendors to ensure they meet production requirements.

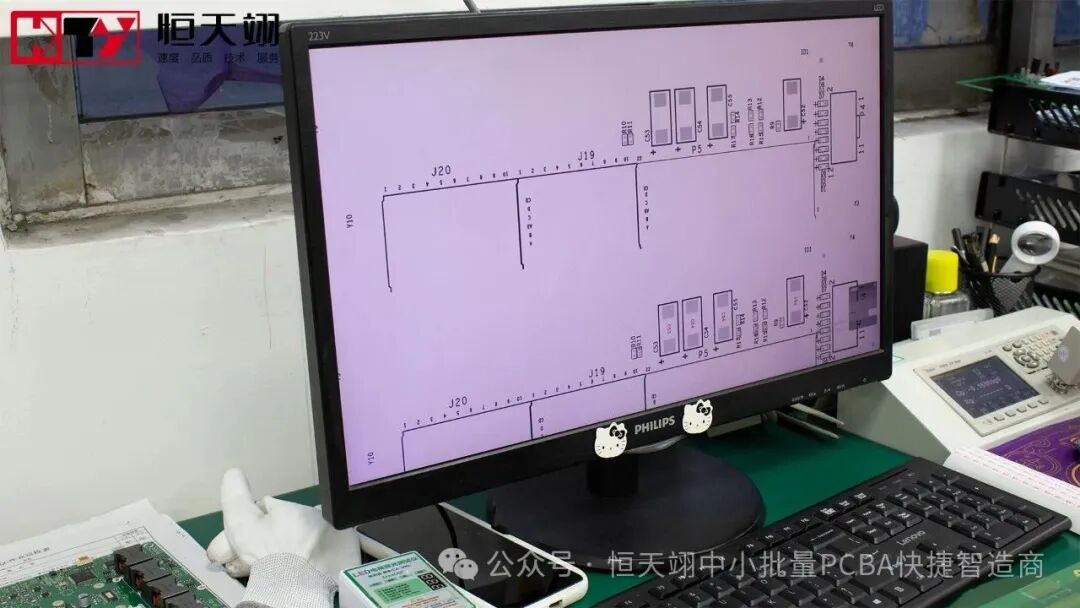

Review Methodology

Various methods are employed during the review process, such as document review, physical inspection, and testing verification, to ensure the effectiveness of the review.

Review Process Records

The review process needs to be clearly documented, including basic information, results, and suggestions for traceability and analysis.

Review Procedure

The review should follow a specific procedure, including preparation, audit, and summary phases, to ensure the review proceeds smoothly.

For PCB manufacturing and PCBA assembly, choose Hengtianyi!

Hengtianyi focuses on one-stop PCBA services, ensuring quality and delivery guarantees. Choosing Hengtianyi means choosing an efficient, professional, and stable PCBA assembly experience. From prototype sampling to mass production, Hengtianyi consistently provides attentive service to every customer. Whether for high-precision PCB manufacturing or fully automated PCBA assembly, Hengtianyi is your trusted partner.

Who to choose for PCBA? Hengtianyi!

Who to choose for assembly? Hengtianyi!

Hengtianyi — Your trusted electronic manufacturing partner!

2. Why Conduct PCBA Production Line Review?

The PCBA production line review is not only a comprehensive inspection of the product design and manufacturing process but also aims to ensure product quality and production efficiency. Through the review, potential issues can be identified and adjusted in a timely manner, thus avoiding production delays and quality problems caused by design defects or unreasonable processes.

Ensure Product Quality

The pre-production review can identify potential issues in the design, such as unreasonable circuit layouts or mismatched pad sizes, thus avoiding quality problems during production. For example, Hengtianyi conducts comprehensive quality testing on PCBA using advanced methods such as flying probe testing to ensure that every circuit board meets customer requirements.

Improve Production Efficiency

During the review process, the manufacturing process can be optimized, reducing unnecessary steps and repetitive operations, thereby improving production efficiency. For instance, Hengtianyi has improved detection efficiency by 40% by introducing machine learning models to predict potential failure points.

Reduce Production Costs

Through the review, design and process issues can be identified in advance, avoiding cost increases due to rework or scrap. For example, Hengtianyi enhances production efficiency and reduces waste through precise feeding and intelligent management.

Meet Customer Needs

The pre-production review ensures that products meet customer requirements and delivery timelines, thereby increasing customer satisfaction. For example, Hengtianyi ensures that all customer requirements are addressed during the review and that delivery timelines are met.

Ensure Production Safety

During the review process, the safety of the production environment and equipment can be assessed to ensure safety during production. For instance, Hengtianyi ensures raw material quality through a strict incoming material inspection system, safeguarding production safety.

Hengtianyi-Centered PCBA Production Line Review Practices

As a company focused on PCBA manufacturing services, Hengtianyi always prioritizes “quality first” as its core philosophy. In terms of pre-production review, Hengtianyi not only emphasizes the review of process documents but also ensures product quality and production efficiency through multi-dimensional reviews.

For example, Hengtianyi ensures the advancement of its quality management system through certifications such as ISO9001, ISO14001, IATF16949, and ISO13485. Additionally, Hengtianyi continuously introduces new quality management tools and technologies, such as the TFT350 automatic testing machine, to ensure that product performance and quality meet customer requirements.

In practice, Hengtianyi holds new product introduction meetings involving multiple departments, including engineering, production, procurement, and quality, to ensure the comprehensiveness and accuracy of the review. For instance, during the review process, Hengtianyi checks the BOM list, optimizes material descriptions, verifies models, packaging, quantities, positions, and improves brand specifications and part number information. Furthermore, Hengtianyi utilizes advanced equipment such as feeders to achieve precise feeding and intelligent management, ensuring the perfect delivery of every circuit board.

The PCBA pre-production review is a key step in ensuring product quality and production efficiency. Through comprehensive reviews, potential issues can be identified, process flows optimized, production efficiency improved, production costs reduced, customer needs met, and production safety ensured. Taking Hengtianyi as an example, its pre-production review not only emphasizes the review of process documents but also ensures product quality and production efficiency through multi-dimensional reviews. In the future, as the electronics industry continues to develop, PCBA pre-production reviews will become more refined and intelligent, providing customers with more efficient and reliable electronic manufacturing solutions.