This function detects the profile of the circuit board loaded into the machine and the F positioning point to perform stop position compensation, maintaining a fixed function. It can effectively address situations where the stop position fluctuates due to differences in the weight or size of the circuit board.

1. Installation of Low-Reflection Board

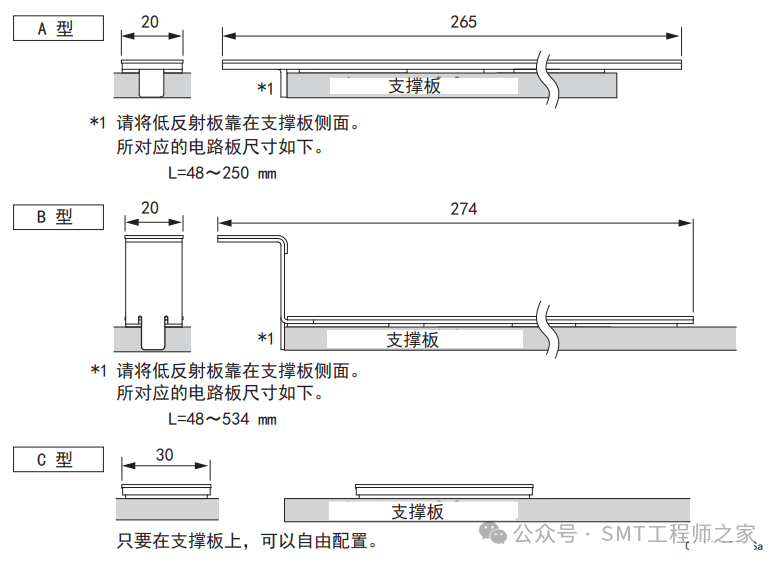

If compensation is performed using the circuit board profile, please set the low-reflection board on the support plate. The low-reflection board can be fixed by the magnets on its back.

(X Direction)

Note: The A-type low-reflection board is not used on the NXT-3c.

(Y Direction)

If the Y coordinate during image processing is set to the default value (12mm), the Y direction setting of the low-reflection board is as shown below.

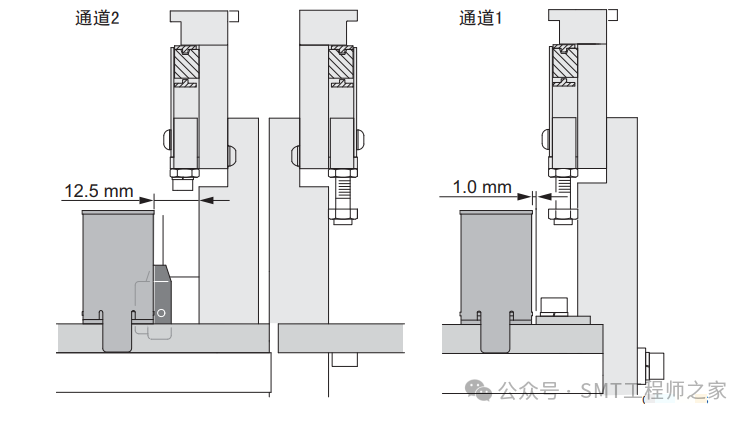

During installation in Track 2, please do not obstruct the light axis of the support pin detection sensor. If the light axis is obstructed, the red light of the light-receiving side sensor will turn off.

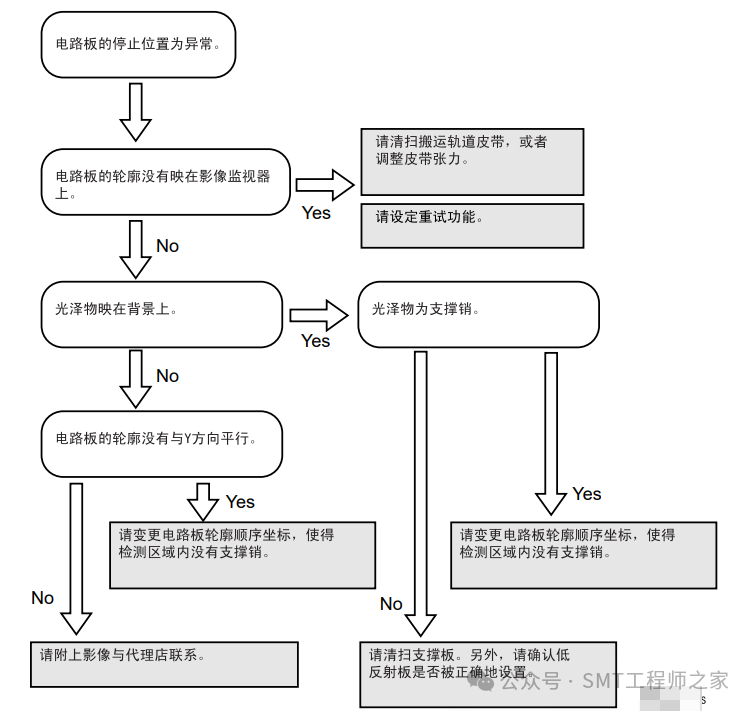

2. Abnormalities When Using the Circuit Board Stop Position Compensation Function

This section describes the abnormalities that may occur when using the circuit board stop position compensation function and their countermeasures.

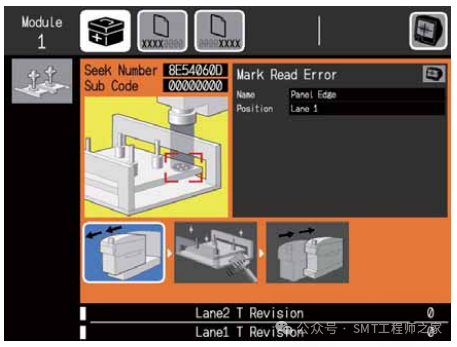

1. Failure to Measure the Circuit Board Profile

An abnormality guide will be displayed on the operation screen.

a. Please press the module pull-out button and pull out the module.

b. Please clean the dirt attached to the low-reflection board on the object track.

c. Then insert the module.

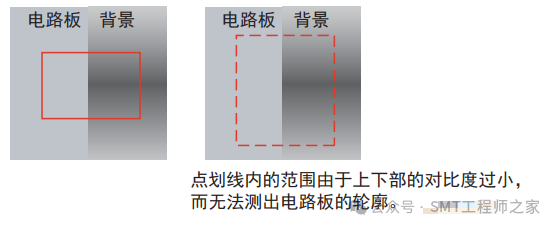

Additionally, after pressing the MONITOR button, you can confirm the status of the image. Compare the circuit board with the background (low-reflection board); if there are areas with low contrast, please change the Job settings as follows.

a. Capture areas with high contrast.

b. Reduce the capture range.

2. Incomplete Stop Position Compensation

If the profile of the circuit board exceeds the set value of ±0.5mm even after two compensation actions, an error screen and Seek Number 8E56 will be displayed. Please take the following countermeasures.

3. Precautions

1. Please do not place shiny objects within the detection area of the circuit board profile.

2. If there is lubricant or similar substances attached to the support plate, it may cause failure in detecting the circuit board profile.

3. After installing the low-reflection board, support pins cannot be arranged around it. The range where they cannot be arranged is as follows.

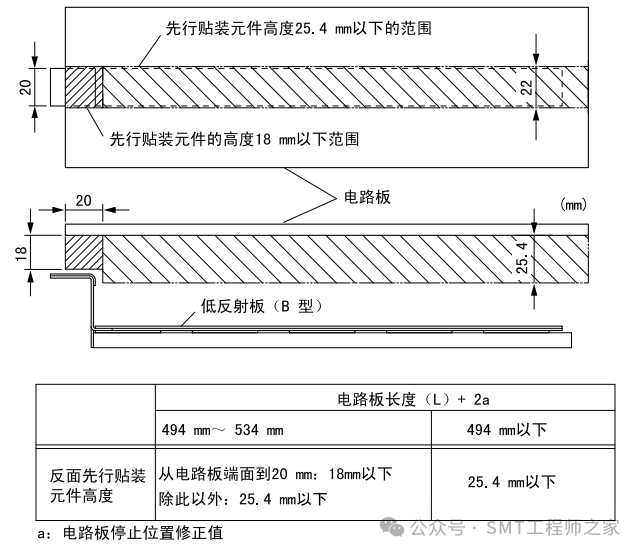

4. There are height restrictions for components installed with B-type low-reflection boards. Please refer to the diagram below.