The semiconductor manufacturing process can be divided into front-end and back-end processes. The front-end process mainly involves wafer manufacturing, while the back-end process primarily focuses on packaging and testing. Among these, packaging (Package) in the back-end process refers to a series of technical methods that connect tested integrated circuit bare chips (Die) to external circuits, providing physical protection and environmental isolation through packaging materials, ultimately forming an independent electronic device that can be installed and operated.

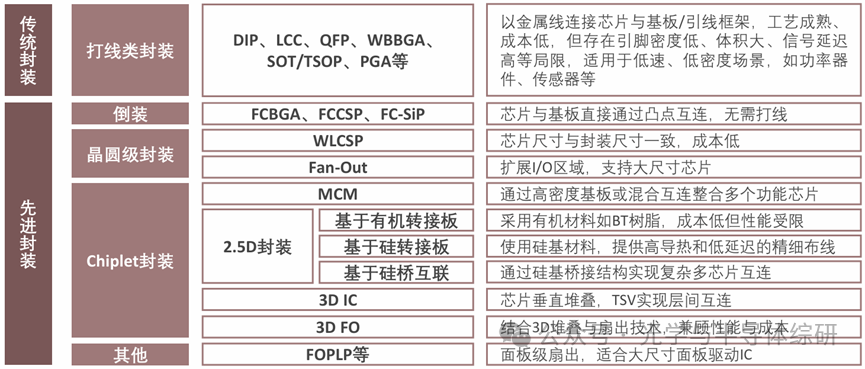

Categories:

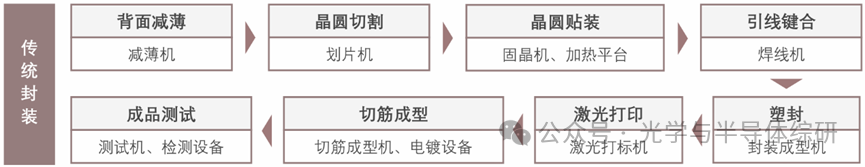

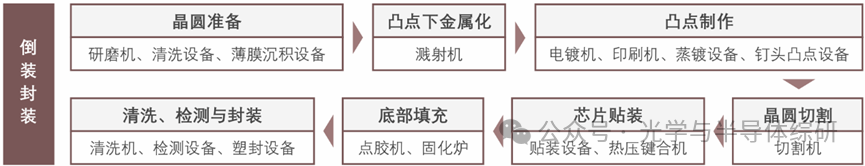

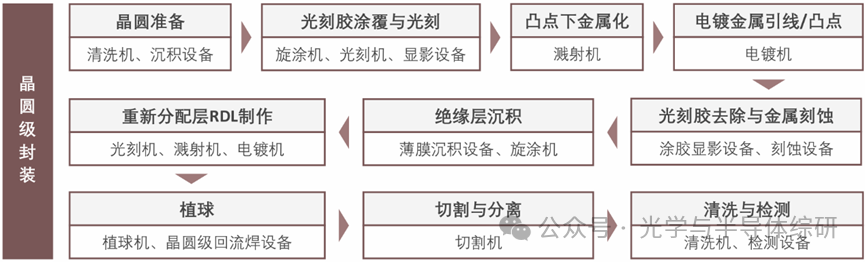

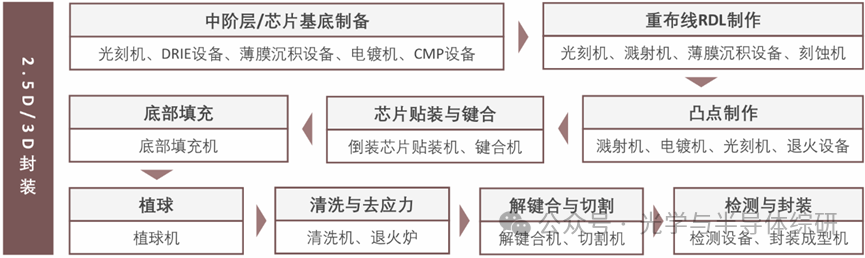

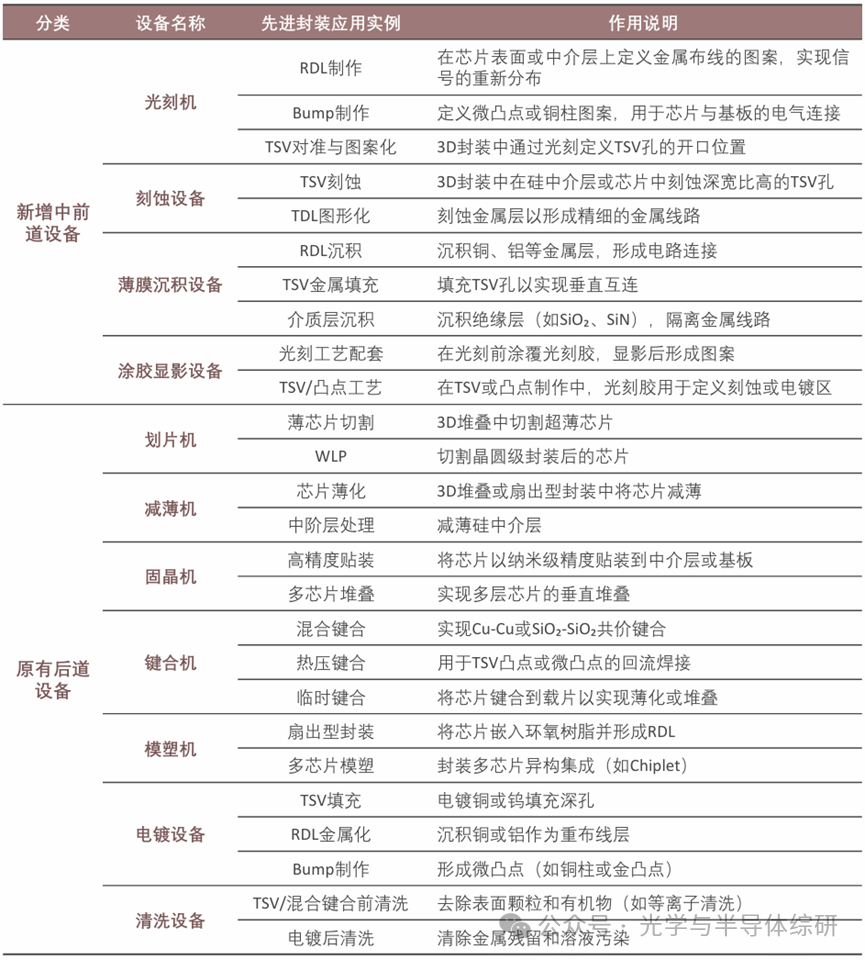

The gap between advanced packaging and traditional packaging processes is significant. Advanced packaging introduces new applications including wafer thinning, RDL production, Bump production, and TSV production, etc. The semiconductor packaging equipment required consists of existing back-end packaging equipment and newly added front-end equipment.

New front-end equipment and existing back-end equipment for advanced packaging

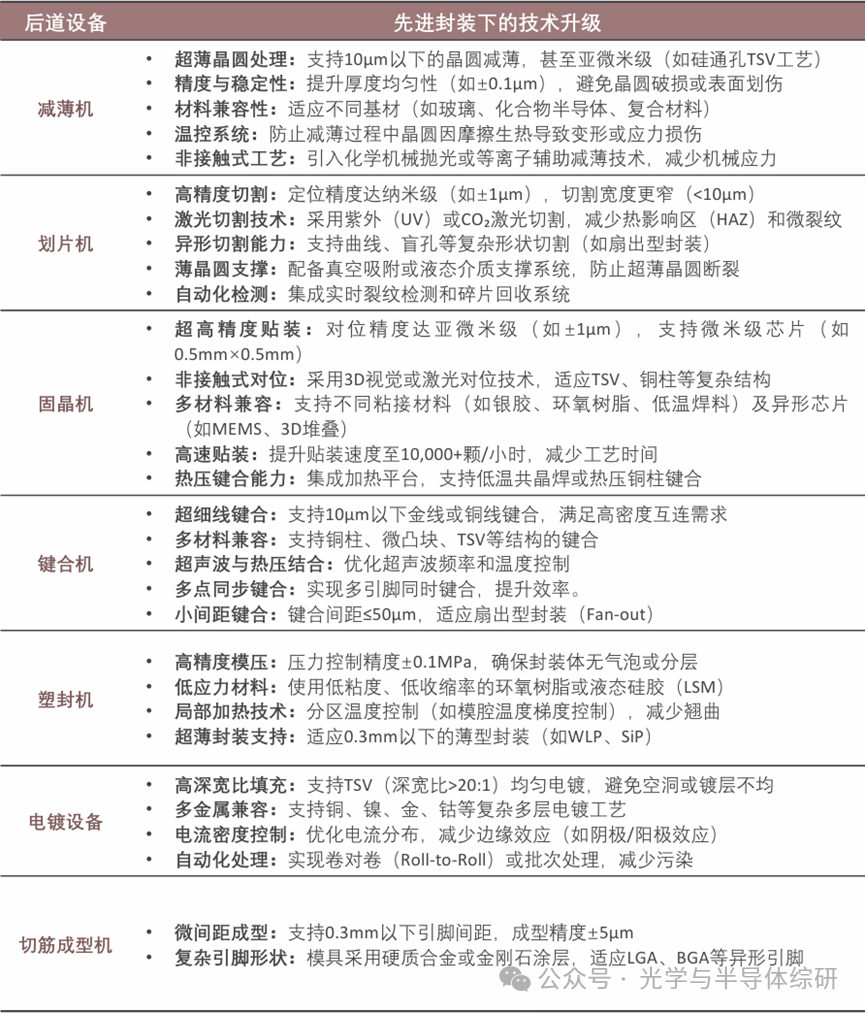

Technological upgrades of traditional back-end equipment under advanced packaging

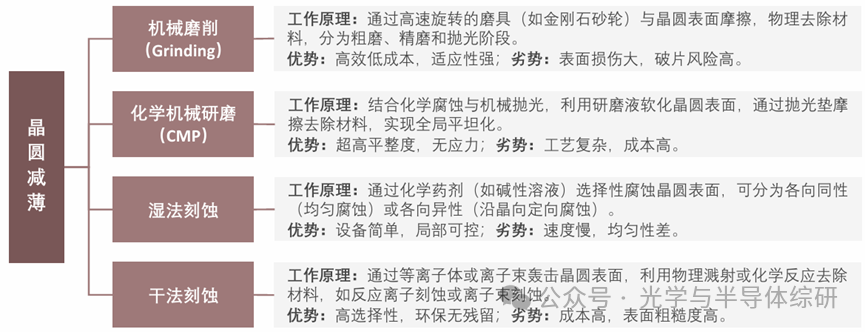

Thinning Machine

The wafer thinning machine (WaferThinningMachine) is a key piece of equipment in semiconductor manufacturing, primarily used for thinning semiconductor wafers to meet the requirements of subsequent processes (such as packaging and testing). Its core functions include reducing wafer thickness, improving surface quality, and adapting to advanced packaging. The wafer thinning process involves mechanically or chemically grinding the back of the wafer to reduce its thickness to a suitable level for packaging. The principle mainly involves methods such as mechanical grinding, chemical mechanical polishing, wet etching, and dry etching to remove material from the wafer surface. During the thinning process, strict control of the wafer’s flatness and thickness is required to ensure the quality and performance of the wafer. The wafer thinning machine is the key equipment for implementing the wafer thinning process. A typical wafer thinning process usually includes several key steps such as preparation, wafer fixation, rough grinding, fine grinding, polishing (optional), cleaning, inspection, and subsequent processing. The typical wafer thickness is about750μm, which can be thinned to around100um (the thickest wafers used for logic gates have a thickness of100µm), to ensure mechanical stability and prevent warping during high-temperature processing. With the increasing use of3D packaging applications, the requirement for wafer thickness to be reduced to50-100um or even below50um will significantly increase the quality demands on thinning equipment. Additionally,DRAM memory typically requires wafers with a thickness of50um, whileMEMS memory usually has a thickness of about30µm.

Dicing Machine

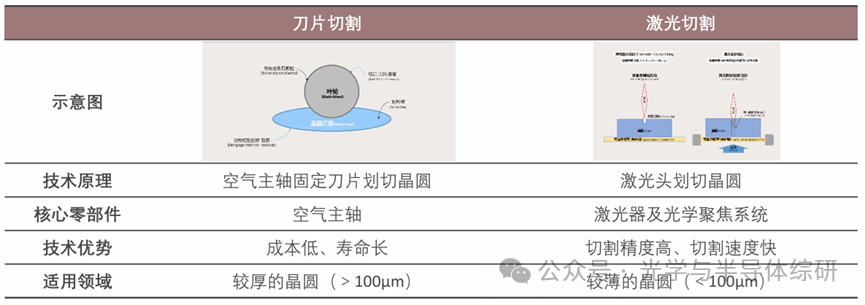

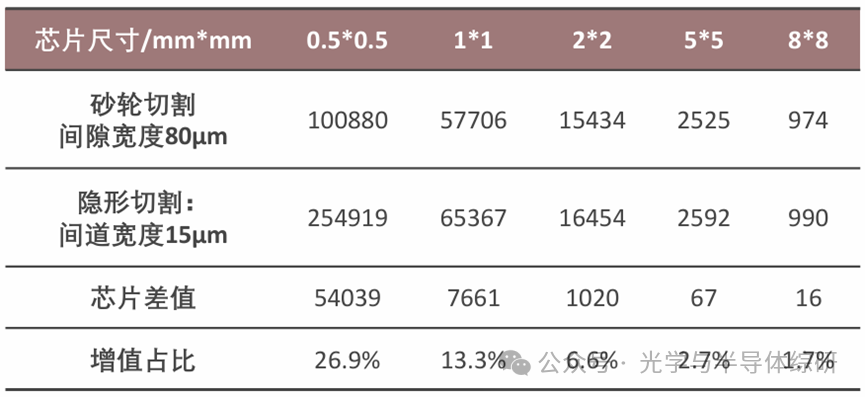

The wafer dicing machine is a device that uses blades or lasers to cut wafers containing many chips into individual chip particles. It is a key piece of equipment in the back-end packaging and testing of semiconductors, specifically in the wafer cutting and WLP cutting stages. The quality and efficiency of the cutting directly affect the quality of the chips and production costs. Depending on the wafer process and product requirements, a single wafer typically consists of hundreds to tens of thousands of small chips, with most wafers having40μm-100μm gaps betweenDice, known as cutting lanes, while99% of the chips on the wafer have independent functional modules (1% are edgeDice, which do not have usable performance). To separate the small chips into individualDice, cutting processes are required. The dicing process mainly includes blade cutting and laser cutting, with laser cutting further divided into traditional laser cutting and laser stealth cutting. Traditional laser cutting requires a protective coating on the wafer surface, followed by applying high-energy laser to cut the silicon along the dicing lanes; while stealth laser cutting first uses laser energy to cut the interior of the wafer, then applies external pressure to the tape attached to the back to cause it to break, thus separating the chips.

In the context of advanced packaging, the application trend of laser cutting (especially laser stealth cutting) significantly surpasses traditional blade cutting, with core advantages including:1) meeting the demand for high precision and low damage, protecting micro-nano structures in advanced packaging;2) flexibly adapting to complex designs, such as thin wafers, heterogeneous integration, and3D stacking.

Die Bonder

The die bonder (Diebonder), also known as a die attach machine, picks up chips from the already diced wafers (Wafer) and places them onto the correspondingDieflag on the substrate, using silver paste (Epoxy) to bond the chip to the substrate. Die bonders can place components at high speed and high precision, achieving key steps such as positioning, alignment, flip-chip, and continuous placement. Packaging die bonders are divided intoFC packaging die bonders,FO packaging die bonders, and2.5D/3D die bonders. According to application types, they can be categorized intoIC die bonders, discrete device die bonders, andLED die bonders (including die attach machines andCOB die bonders), mainly used in the packaging processes of semiconductor chips, optical chips, optical modules, silicon photonic devices, sensors, etc.

Due to advanced packaging technologies such as3D stacking, system-in-package (SiP), and fan-out wafer-level packaging (FOWLP), which require handling smaller components, denser layouts, and more complex structures, the precision and efficiency requirements for die bonders have increased significantly. In terms of precision, current domesticIC die bonders generally have a precision of±25μm or more, while the international leading level is±3~5μm, with high-end models reaching±1μm (such asASMPTCOS die bonders). Under advanced packaging demands,3DNAND,HBM, etc., require precision to reach±1~3μm, to ensure precise alignment and increased interconnection density between chips and substrates; in terms of efficiency, current domestic equipment has a UPH of about12-15K, while international leading mid-to-high precision equipment can reach15-20K, and high-speed models (such asASMPTFC/FB series) can exceed25K. In advanced packaging production lines, to meet high capacity demands, UPH needs to be increased to20K or even30K.

Bonding Machine

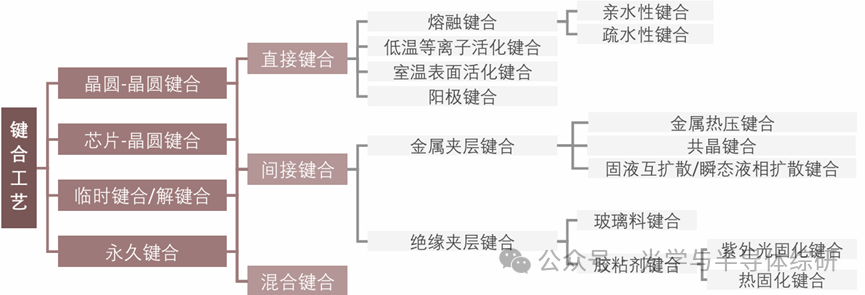

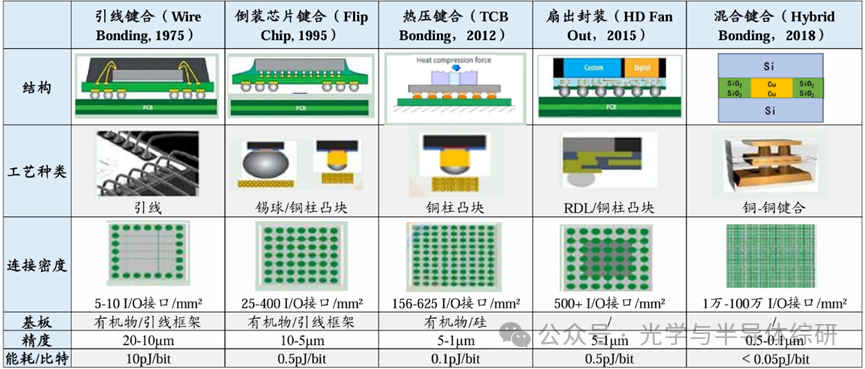

Bonding (Bonding) is the process of attaching two smooth and clean wafer surfaces together using physical or chemical methods, to assist semiconductor manufacturing processes or to form heterogeneous composite wafers with specific functions. There are various types of bonding technologies, classified into wafer-to-wafer bonding (Wafer-to-Wafer,W2W) and die-to-wafer bonding (Die-to-Wafer,D2W); based on whether debonding is required after bonding, they can be divided into temporary bonding (TemporaryBonding) and permanent bonding (PermanentBonding); and based on whether auxiliary interface layers are introduced, they can be divided into direct bonding, indirect bonding, and hybrid bonding (HybridBonding). Additionally, traditional bonding methods such as wire bonding (WireBonding) are gradually being replaced by advanced methods such as flip-chip bonding (FlipChipBonding) and hybrid bonding.

With the continuous advancement of packaging technology, bonding equipment now needs to achieve higher precision and finer energy control. According to data fromBesi, driven by the latest hybrid bonding technology, bonding precision has significantly improved from the original5-10/mm² to10K-1MM/mm², while energy consumption has been significantly reduced to only0.05pJ per bit. Entering the post-Moore era, the focus of packaging technology has shifted to improving transmission efficiency and reducing chip size. Traditional wire bonding technology completes electrical connections using metal wires, but due to physical space limitations and signal delay issues, it is difficult to meet the demands of modern advanced packaging. To overcome these challenges, thermal compression bonding (TCP) and hybrid bonding (HybridBonding) are seen as key technological development directions. In particular, hybrid bonding technology replaces traditional wires with copper contacts, achieving direct electrical interconnection between wafers, resulting in more than ten times the interconnection density compared to the past. However, this method places extremely high demands on the smoothness, cleanliness, and alignment precision of the wafer surfaces. Currently, hybrid bonding technology is mainly applied in high-performance storage fields, such asHBM and3DNAND.

Packaging Machine

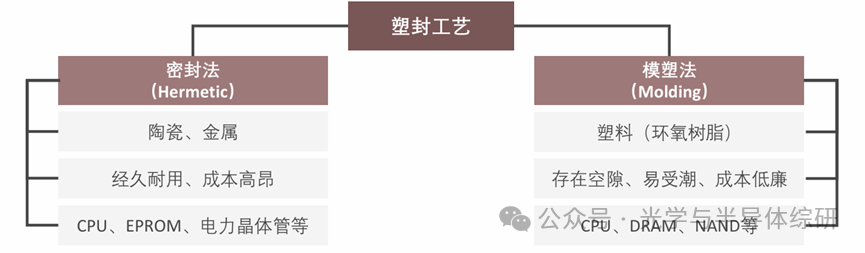

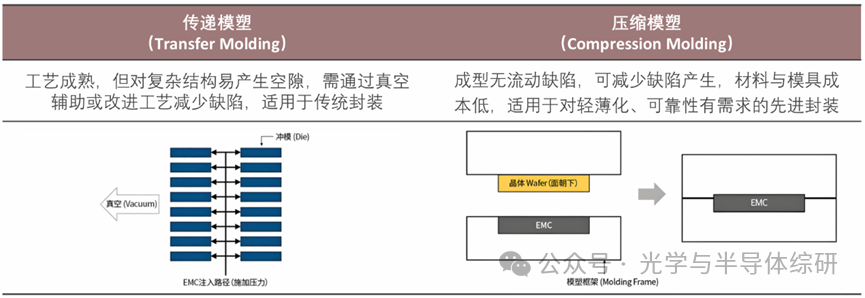

The packaging machine is a device that encapsulates chips in plastic (such as epoxy resin) or other materials, with the core function of providing physical protection and electrical insulation for the chips, firmly bonding the chip, lead frame, or substrate with the package, ensuring signal transmission and heat dissipation performance. The packaging process typically includes the following steps: chip placement, preheating and mold closing, injection molding/pressure transfer, curing, trimming, and forming. The packaging process can generally be divided into hermetic sealing (Hermetic) and molding (Molding): hermetic sealing refers to attaching ceramic or metal covers for sealing; molding refers to melting and then curing plastic epoxy materials for sealing. Among these two methods, hermetic sealing is currently rarely used, while molding using epoxy resin is more commonly adopted. Molding can be further divided into transfer molding (TransferMolding) and compression molding (CompressionMolding): transfer molding pushes melted epoxy resin through narrow channels in the mold under pressure, injecting it into the mold cavity, and curing it into shape. The transfer molding process is mature but can easily produce voids in complex structures (such as multi-layer chips), requiring vacuum assistance or improved processes to reduce defects, making it suitable for traditional packaging; compression molding directly places epoxy resin particles into the mold, heating and melting them, then applying high pressure to ensure uniform filling and curing. Compression molding has advantages such as defect detection, low cost, and minimal environmental impact, making it particularly suitable for advanced packaging scenarios that require lightweight and high reliability (such asWLCSP, multi-layer packaging).

Source: Semiconductor Materials and Process Equipment

Engineer Zhao

13488683602

Submission/Promotion/Group Joining/ Reprint