Generally speaking, manufacturers purchase various programmable ICs from semiconductor manufacturers, and the data area is blank. Before assembly, the latest version of the control program and data can only be written using an IC programmer. This is a necessary process, more important than IC testing. Generally, it is completed by the final electronic manufacturer, which is also part of the production and manufacturing process, making it more prone to errors and requiring more debugging and correction. 1. What is chip programming?

Programming refers to the process where programmers write programs and import them into the target IC to perform a complete action.

The process of programming is known as programming here, and in some places, it is called IC copy. In our country, it is commonly referred to as programming. Programming (generally) refers to using a burner to write data (also called burning) onto a recording disk. For example, CD and DVD recording disks, the latter has a much larger capacity than the former. Programming is like copying. It involves copying things from your computer onto another storage medium, similar to how a 1.4-inch disk can be considered a type of programming disk. However, a GBA card is a programming card but cannot be called a burning card. Programming and burning are essentially the same process; however, different terms are used depending on the medium. An IC programmer is essentially a tool that writes data to programmable integrated circuits, mainly used for programming (or flashing) chips such as microcontrollers (including embedded systems) and memory (including BIOS). Manufacturers buy various programmable ICs from semiconductor companies with blank data areas, and before assembly, the control program and data are written using an IC programmer, which is a necessary process even more important than IC testing, usually performed by the final electronic product manufacturer.

2. Why do ICs need to be programmed? First, because electronic products have microcontrollers or ARM controllers. During the production process, the control chip initially contains no programs. To ensure that the microcontroller or ARM chip operates according to our designed functionality, we need to program the compiled executable files into the control chips of our electronic products. Second, corresponding parameters need to be programmed. After programming the microcontroller or ARM program, sometimes for confidentiality, parameters may need to be set through interfaces such as serial ports or USB, or part of the parameters may need to be programmed, such as the IP address and port data of a Wi-Fi module. This is all to ensure that the electronic product can function normally. Third, programming files, such as font libraries, images, ringtones, animations, etc. Many electronic products now have displays, and to enhance user experience, pre-processed high-definition photos need to be programmed into the storage of the microcontroller or ARM system. Font library files are used for users to input Chinese characters in electronic products.

In summary, the purpose of including this program in the IC is to ensure the normal operation of the microcontroller system or ARM chip and the essential files and parameters for safe operation.

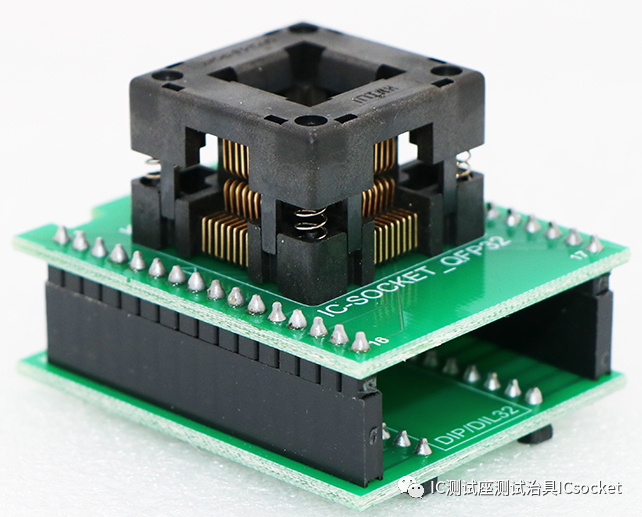

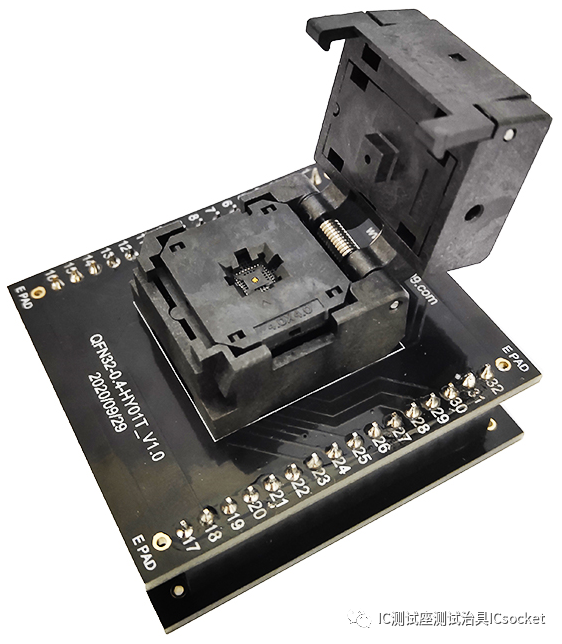

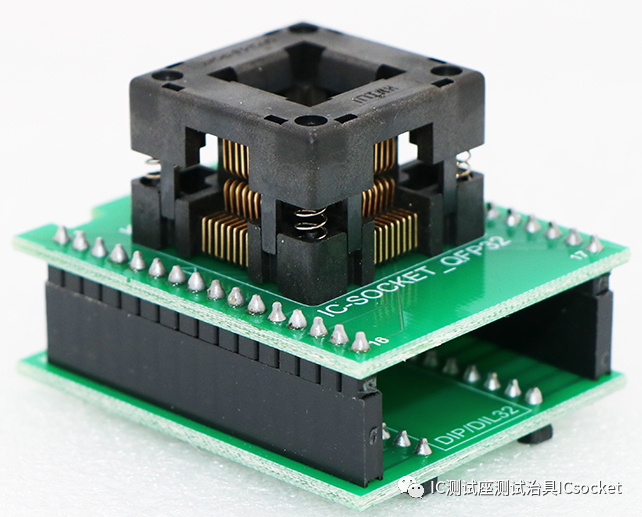

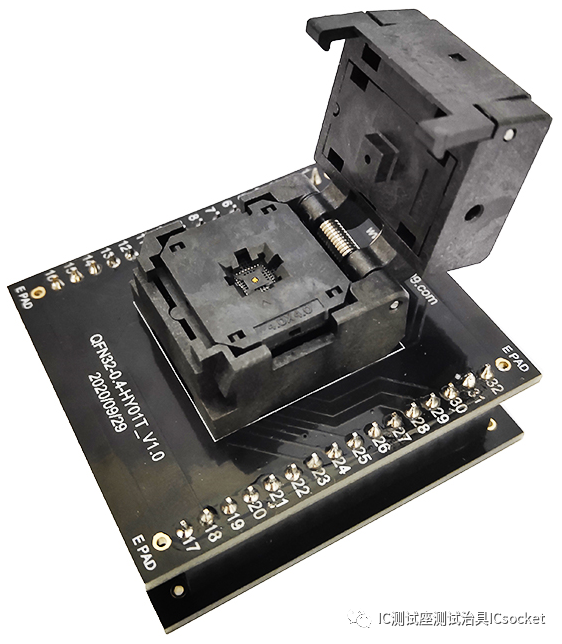

Our company provides various IC programming sockets and programming fixtures for common packages such as QFN, TQFN, DFN, QFP, LQFP, TQFP, SOP, SSOP, TSSOP, BGA, FBGA, LBGA, LGA, WLCSP, CPS, and more.

Our company has focused on the research and production of various standard and non-standard packaging test sockets/fixtures/sockets/jigs for over twenty years, providing customers with professional integrated circuit testing, programming, aging tests, and other connection solutions. We specialize in the research and production of various high-performance, low-cost Burn-in & Test Sockets and various IC testing fixtures suitable for multiple packages: BGA, PGA, QFN, GCSP, CLCC, QFP, TSOP…