The control system is a crucial component of industrial robots, functioning similarly to the human brain. Having a well-functioning, sensitive, and reliable control system is key for industrial robots to coordinate actions with equipment and complete tasks together. The control system of industrial robots generally consists of two parts: control of their own movements and coordinated control with surrounding equipment. Please pay attention to: Rongji Igniter

1. Characteristics of Industrial Robot Control Systems

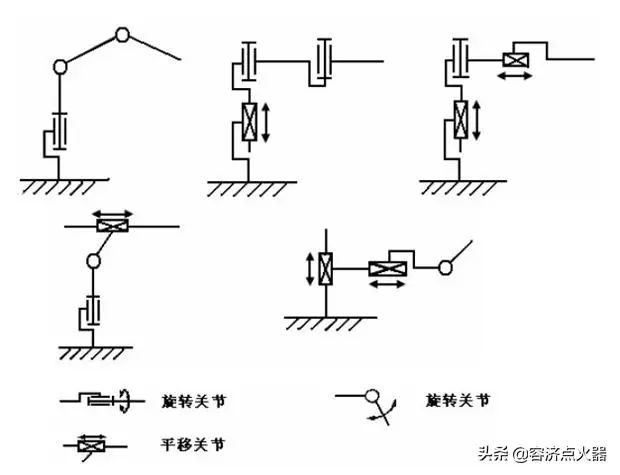

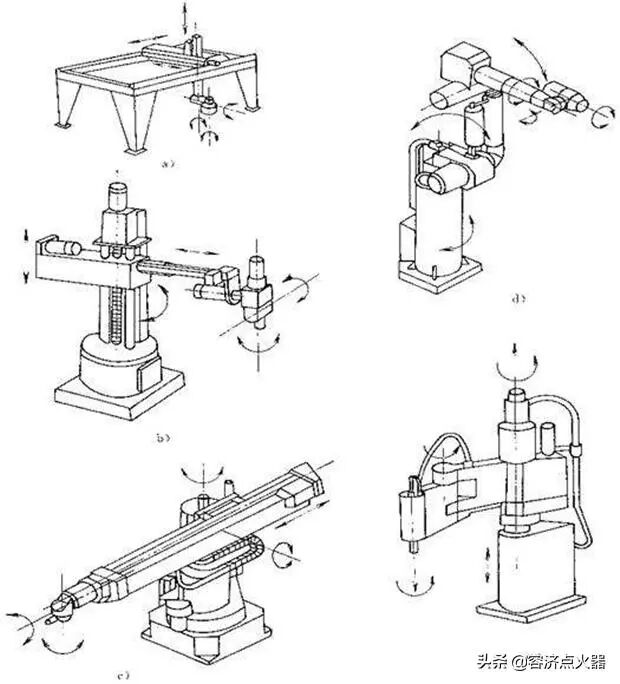

Structurally, robots belong to a spatial open-chain mechanism, where the movements of each joint are independent. To achieve the motion trajectory of the end effector, multi-joint motion coordination is required, making the control system much more complex than ordinary control systems.

The characteristics of robot control systems are as follows:

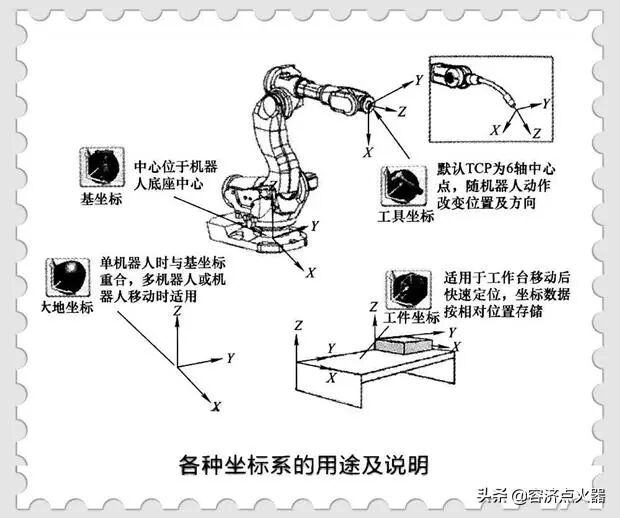

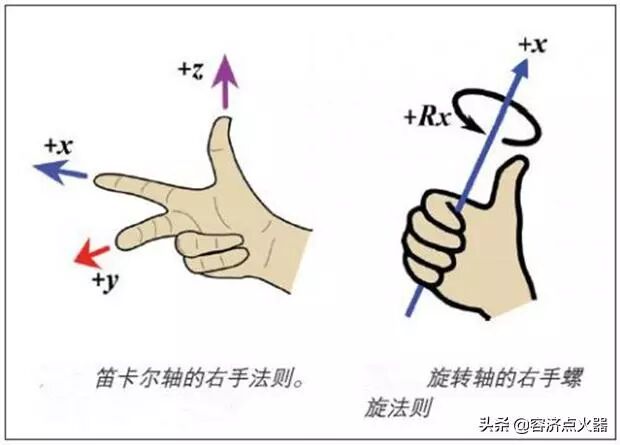

(1) The control of robots is closely related to the kinematics and dynamics of the mechanism. The state of the robot’s limbs can be described in various coordinates, and the reference coordinate system should be selected based on specific needs, requiring appropriate coordinate transformations. Solutions for forward and inverse kinematics are often needed, and the effects of inertial forces, external forces (including gravity), and centripetal forces must also be considered.

(2) Even a relatively simple robot requires at least 3 to 5 degrees of freedom, while more complex robots may require dozens of degrees of freedom. Each degree of freedom generally includes a servo mechanism, which must coordinate to form a multivariable control system.

(3) The coordination control of multiple independent servo systems is implemented by a computer, allowing the robot to act according to human intentions, even endowing the robot with certain “intelligent” tasks. Therefore, the robot control system must be a computer control system, with the software undertaking significant responsibilities.

(4) Since the mathematical model describing the robot’s state and motion is nonlinear, its parameters change with state alterations and external force variations, and there is coupling between variables. Thus, merely using position feedback is insufficient; velocity and even acceleration feedback must also be employed. Methods such as gravity compensation, feedforward, decoupling, or adaptive control are often used in the system.

(5) Since the robot’s actions can often be completed in various ways and paths, there exists an “optimal” problem. For advanced robots, artificial intelligence methods can be employed, utilizing computers to establish a vast information database, which aids in control, decision-making, management, and operation. By obtaining the conditions of objects and environments through sensors and pattern recognition methods, the best control laws can be automatically selected according to given performance criteria.

In summary, the robot control system is a coupled, nonlinear multivariable control system closely related to the principles of kinematics and dynamics. Due to its uniqueness, classical and modern control theories cannot be directly applied. To date, the theory of robot control is still not complete and systematic.

2. Main Functions of Industrial Robot Control Systems

The control of the motion position, posture, trajectory, operation sequence, and timing of actions of industrial robots in the workspace is the primary task of the industrial robot control system, some of which are quite complex. The main functions of the industrial robot control system include the following two points:

(1) Teaching and Reproduction Function. The teaching and reproduction function refers to the control system’s ability to teach the robot the sequence of actions, motion speed, position, etc., through a teaching box or manual teaching. The robot’s memory device automatically records the taught operation process in memory, and when reproduction is needed, the stored content can be replayed. If the operation content needs to be changed, it can simply be taught again.

(2) Motion Control Function. The motion control function refers to the control of the end effector’s pose, speed, acceleration, and other parameters of the industrial robot.

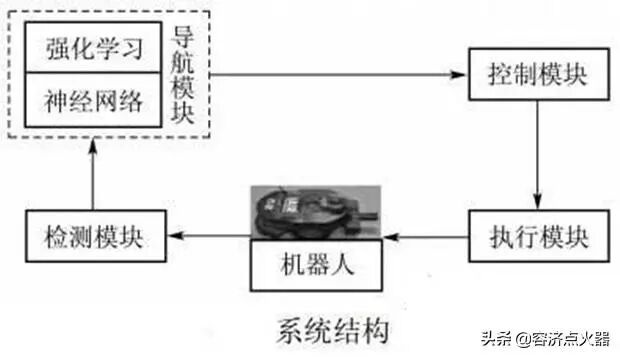

3. Composition of the Control System

The control system of industrial robots consists of corresponding hardware and software.

(1) Hardware.

The hardware mainly includes the following parts:

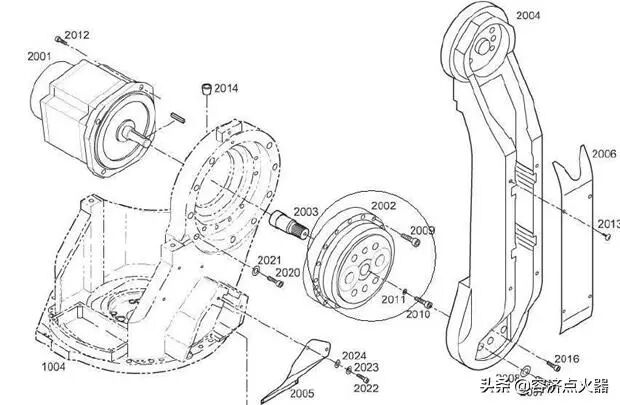

1) Sensing Devices. These can be divided into internal sensors and external sensors. The former is used to perceive its own state, detecting the position, speed, and acceleration of each joint of the industrial robot; the latter is used to sense the working environment and the state of the working objects, including visual, tactile, auditory, and haptic sensors.

2) Control Device. Generally consists of a micro or small computer and corresponding interfaces. Its role is to process various sensory information, execute control software, and generate control commands.

3) Joint Servo Drive Part. This part’s main function is to drive each joint’s movement based on the control device’s instructions according to the task requirements.

(2) Software.

The software referred to here mainly pertains to the robot’s control software. The control software consists of motion trajectory planning algorithms, joint servo control algorithms, and corresponding action programs. It can be written in any programming language, but the mainstream of industrial robot control software is developed using modularized general-purpose languages to form specialized industrial languages.

4. Names and Functions of Each Component of the Industrial Robot Control System

(1) Control Computer. The control computer is the scheduling and command institution of the control system, generally using microcomputers or microprocessors. (2) Teaching Box. The teaching box is used to teach the robot’s working trajectory, parameter settings, and all human-machine interaction operations. It has an independent CPU and storage unit, communicating with the main computer via serial communication.

(3) Operation Panel. The operation panel consists of various operation buttons and status indicator lights, and its function is to complete basic operational tasks.

(4) Disk Storage. Hard disks and floppy disks serve as the storage for the robot’s working programs.

(5) Digital and Analog Input/Output. This part is responsible for the input or output functions of various states and control commands. (6) Printer Interface. The printer interface is used to record various information that needs to be output.

(7) Sensor Interface. The sensor interface is used for automatic detection of information, achieving compliant control of the robot, generally including force, touch, and visual sensors.

(8) Axis Controller. The axis controller is responsible for controlling the position, speed, and acceleration of each joint of the robot.

(9) Auxiliary Device Control. Auxiliary device control is used to control auxiliary devices that cooperate with the robot, such as gripper positioners.

(10) Communication Interface. The communication interface is used for information exchange between the robot and other devices, generally including serial and parallel interfaces.

(11) Network Interface. The network interface includes Ethernet and Fieldbus interfaces.

1) Ethernet Interface. The Ethernet interface allows for direct PC communication with multiple or single robots, with a data transfer rate of up to 10Mb/s. It supports application programming on PCs using Windows 95 or Windows NT library functions, supports TCP/P communication protocols, and can load data and programs into various robot controllers via the Ethernet interface.

2) Fieldbus Interface. Supports various popular fieldbus specifications, such as DeviceNet, ABRemote I/O, Interbus-S, Profibus-DP, M-NET, etc.

This article is sourced from: Rongji Electromechanical Technology.

For more technical information, click to read the original article;

Like to see on!