Industrial robots are the “crown jewel” of China’s manufacturing industry. In the research and manufacturing of core components for robots, China has approached the international top level in many areas. However, some core technologies still fail to meet the application needs of complex high-end fields. Issues such as unclear competition mechanisms between the transmission precision and lifespan of precision reducers, low dynamic identification accuracy of controllers, unclear influence mechanisms of multi-physical factors on the limit torque of servo systems, and the absence of an advanced core component evaluation technology system urgently require research and application on the performance improvement of core components in robots.

Industrial powerhouses such as the United States, Europe, and Japan have long been committed to the research of high-end precision reducers for robots. Companies like Harmonic Drive and Nabtesco have systematically carried out gear shape optimization design and high-precision processing technology research. Nabtesco’s RV-N and RV-C series of RV reducers have a rated lifespan exceeding 10,000 hours, with angular transmission precision not greater than 1′. Harmonic Drive has developed over 20 series of harmonic reducer products like CSF/CSG, with a rated lifespan exceeding 10,000 hours and a stiffness reduction rate not greater than 50%, widely used in robotics, aerospace, and medical devices, accounting for over 70% of the market share.

In China, a number of precision reducer companies and research institutions represented by Shaanxi Qinchuan, Shenzhen Dazhuo, and Chongqing University have emerged, achieving significant accomplishments in the field of precision reducers. Chongqing University has made breakthroughs in the multi-tooth meshing effect and load distribution mechanism of reducers, supporting the development of domestic precision reducers. Shaanxi Qinchuan has developed the BX series RV precision reducers. Shenzhen Dazhuo has developed the LHS(G) and HMCS/HMHS series of harmonic reducers with double arc teeth, with a rated lifespan of 8,000 hours, gradually replacing foreign mid-to-high-end products. However, there are still gaps in precision retention, reliability, and batch processing consistency of high-end products.

1.1 Transmission Precision

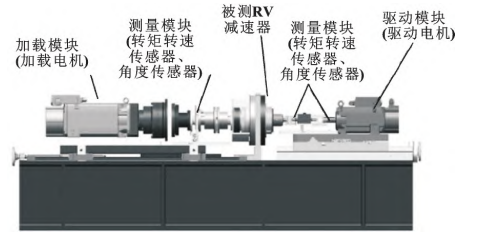

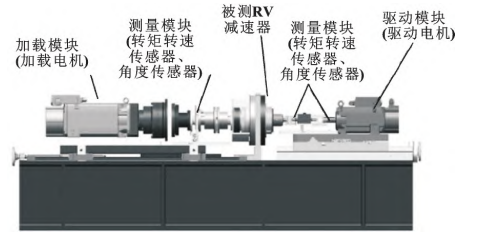

Due to manufacturing and assembly errors in the crankshaft of RV reducers, these errors affect the transmission precision and efficiency of the reducers, significantly reducing their load capacity. To improve the design precision of the crankshaft, Xi Ying and others established a mathematical model of the crankshaft of the reducer by analyzing the impact of crankshaft eccentricity on the reducer. Their MATLAB calculations suggest that the crankshaft eccentricity should be 1.3mm, which greatly aids in improving precision and reducing backlash. The load capacity of the reducer spindle is also crucial for its precision. Wang Chaojun and others found through analysis of the force model of the spindle that when the contact angle is between 30° and 50°, the spindle has a greater load capacity. Additionally, in the design and manufacturing of the spindle, the processing technology should be strictly controlled, balancing processing economy with better performance. Meanwhile, Wang and Mao constructed an experimental platform for the robot reducer to accurately measure the transmission error of two common models under different conditions, as shown in Figure 1.

Figure 1 Experimental Structure

Analysis yielded an error curve, based on experimental data showing that the error of the RV reducer increases with load and input speed, and decreases with increased stiffness, with load having the most significant impact on transmission precision. Yang and others established a transmission error model by combining the meshing characteristics of the first-stage involute gear reduction and the second-stage cycloidal pinwheel reduction, providing a detailed explanation of the relationship between original transmission error and output error through numerical analysis and experiments, offering significant theoretical guidance for the study of transmission precision in reducers.

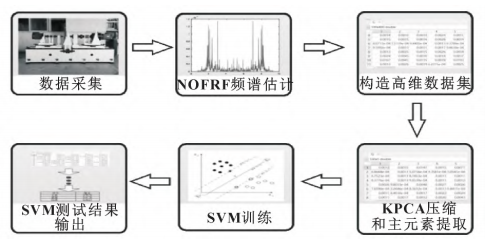

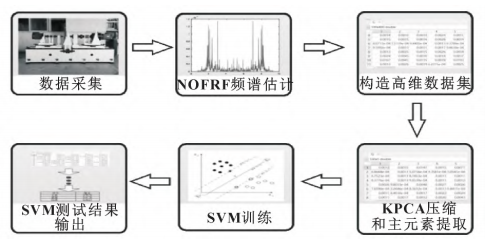

The accuracy of fault diagnosis for RV reducers used in robots has historically been low. To address this issue, Chen Lerui and others utilized a combination of nonlinear output frequency response kernel principal component analysis to diagnose faults in RV reducers. Their process is illustrated in Figure 2. By employing batch estimation methods, they obtained the first four-order spectral values for each state, and then used this data to test a support vector machine classifier, with results indicating a significant improvement in accuracy compared to traditional methods that only measure time-domain and frequency-domain vibration signals.

Figure 2 Fault Diagnosis Process Based on NOFRF Spectrum

Building on this, Liu Yongming and others proposed a fault diagnosis model based on EEMD and a particle swarm optimization (PSO) optimized extreme learning machine (ELM), which effectively reflects the periodic characteristics of data. Experimental results demonstrate that this model can more effectively determine the working status of RV reducers. Meanwhile, Lin Mengxiong and others found that the previously used reciprocating swing method for fault analysis of precision reducers made it very difficult to locate the fault source. They proposed a harmonic tracking analysis method, which involves resampling the non-stationary signals of the reducer to obtain stable angular domain signals and performing fast Fourier transformation, achieving fault diagnosis of planetary cycloidal pinwheel reducers under variable speed experimental conditions. The results indicate that the proposed harmonic tracking analysis method can effectively locate faults in important components of the planetary cycloidal pinwheel reducer under time-varying conditions, providing guidance and assistance for rapid fault location during swing fatigue experiments.

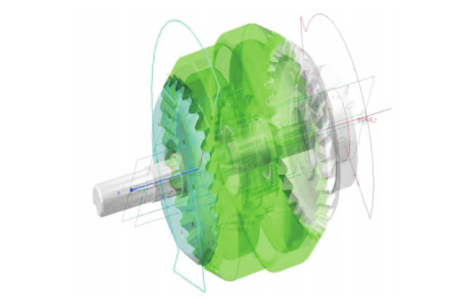

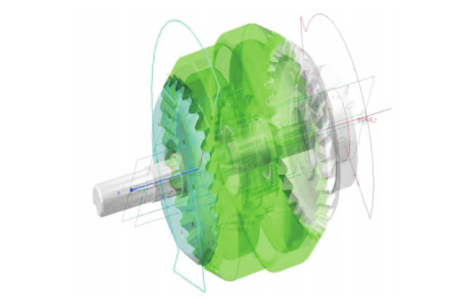

To further explore the dynamic characteristics of RV reducers used in robots, Xi Ying and others utilized the powerful dynamic simulation capabilities of Adams. After obtaining the structural parameters and material properties of the RV reducer through metallographic experiments and combining MATLAB calculations, they derived the dynamic parameters. Based on model simplifications, they achieved a reasonable dynamic model of the reducer, with the output values on the planetary frame having an error within 0.8′, ultimately obtaining a highly accurate dynamic model, as shown in Figure 3.

Figure 3 RV Reducer Adams Model

Lu Qi and He Weidong established a dynamic simulation model considering bearing clearance, tooth contact, and contact between pins and pin slots based on multi-body dynamic simulation technology. They analyzed the small-cycle factors affecting the angular transmission error of RV reducers by selecting the center circle diameter of the pins and the diameter of the pin slots within the same assembly size chain and conducting dynamic simulations under rated conditions to analyze the variation of angular transmission errors. Yu and others analyzed the characteristics of the additional torque generated by RV reducers and the no-load operation characteristics of RV reducers, proposing a new method for measuring the torque of RV reducers during no-load operation using singular value decomposition filtering to eliminate the influence of additional torque and analyze its dynamics.

To further study the dynamic characteristics of reducers, Pang Jie and Han Zhenan employed the concentrated parameter method to analyze variations in meshing force by changing meshing stiffness. With increased meshing stiffness, the meshing force during the transmission process becomes more stable within a certain range, laying a foundation for fault diagnosis and optimization design of RV reducers.

The controller is the brain of the robot, determining its functionality and performance. Companies like Austria’s Keba and Switzerland’s ABB have formed solid technical barriers in the field of robot controllers, leveraging their past advantages in the automotive industry. Keba’s KeMotion achieves real-time control by integrating Automation Runtime and supports various real-time Ethernet buses such as EtherCAT and SercosIII. ABB has incorporated a new generation of force control solutions into its robot controller IRC5, effectively enhancing the robot’s dynamic response and motion accuracy. Research institutions represented by Beihang University, GSK Technology Co., Ltd., Guangshu, Huashu, and Chongqing University have made significant breakthroughs in domestic robot controllers, with comprehensive performance indicators comparable to international advanced levels.

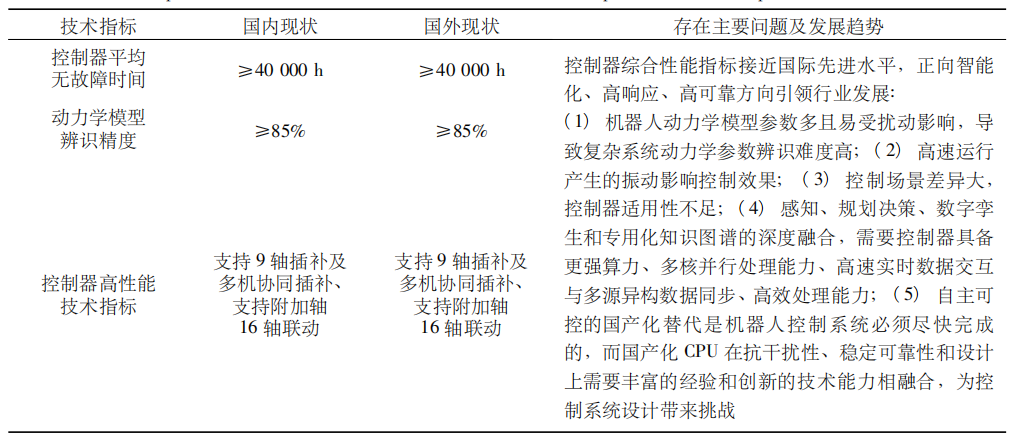

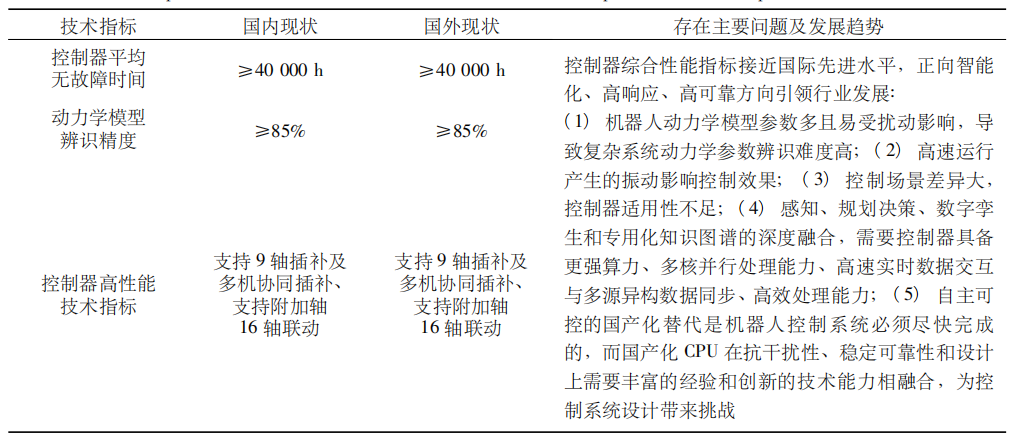

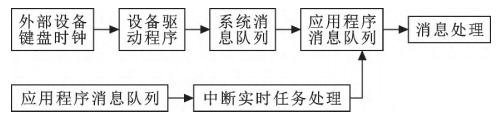

Beihang University proposed a load identification method for 6R industrial robots, while Chongqing University made breakthroughs in distributed adaptive tracking control strategies for unknown network Lagrangian systems, providing support for the development of high-performance robot controllers. GSK has developed a drive-control integrated robot motion control platform, which matches foreign competitors in terms of reliability and flexible scalability. As robots evolve towards intelligence, high responsiveness, and high reliability, higher demands are placed on controllers, necessitating breakthroughs in key technologies such as flexible scalability, high-performance high-reliability control design, high-precision automatic identification of dynamic parameters, and high-speed stable operation with vibration suppression, as shown in Table 1.

Table 1 Comparison of Domestic and International Technical Indicators of Controllers, Existing Issues, and Development Trends

The mainstream control method currently is “motion control,” which uses feedback from the deviation between the robot’s desired trajectory and its actual trajectory. This method may lead to motion jitter for high-precision robots. To eliminate jitter, researchers have adopted a “dynamic control” method, utilizing the excellent real-time characteristics of B&R controllers to obtain various data from the robot. After completing the static parameter identification of the robot and obtaining an accurate mathematical model of the robot system, better dynamic performance can be ensured, achieving feedforward control.

2.2 Control Method Design

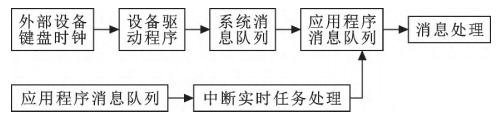

Self-controllable domestic alternatives are essential for the rapid completion of robot control systems, while domestic CPUs require a blend of rich experience in anti-interference, stable reliability, and innovative technical capabilities, posing challenges for control system design. Researchers proposed a new hardware architecture for robot controllers, using a universal IPC as the hardware platform and the Windows operating system as the software platform, achieving both PTP and CP control modes, and providing methods for writing interrupt service programs in a Windows environment, as shown in Figure 4. This represents a significant improvement over traditional hierarchical control methods.

Figure 4 Interrupt Response Process in Windows Environment

Additionally, based on the dynamics equations of the robot controller’s anti-interference design, researchers designed an industrial robot control technology based on DOB technology, significantly enhancing the controller’s anti-interference capabilities.

The servo system is the power core of the robot. Currently, the domestic servo drive system market is mainly divided into three categories: Japanese, European and American, and domestic products, with mainstream products including Yaskawa’s Σ7 series, Mitsubishi’s J5 series, and Kollmorgen’s AKD series, Huichuan’s SV660 series, and Hechuan’s X6 series. However, in the high-end servo field, foreign products still dominate, with Japanese brands like Yaskawa, Mitsubishi, Panasonic, and German Siemens accounting for over 75% of the market share. Yaskawa’s Σ7 series servo systems have a maximum speed of 6000r/min, torque ripple less than 1%, overload capacity exceeding three times, and high-frequency vibration suppression capabilities of over 500Hz and under tens of Hz, with speed fluctuations less than 0.1%.

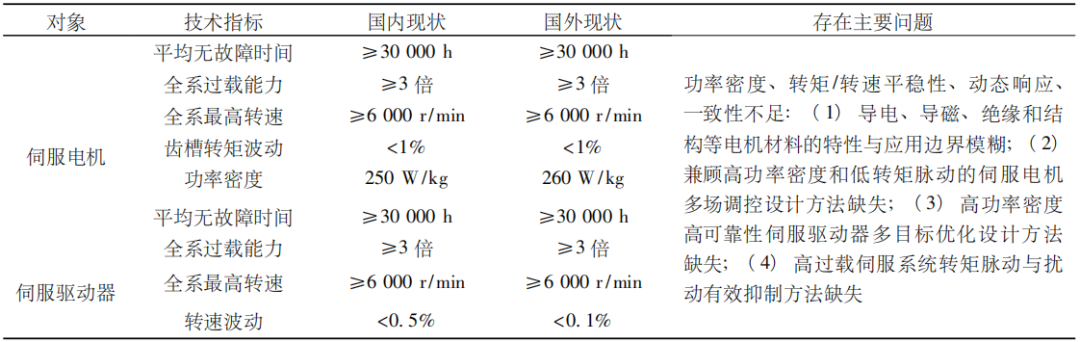

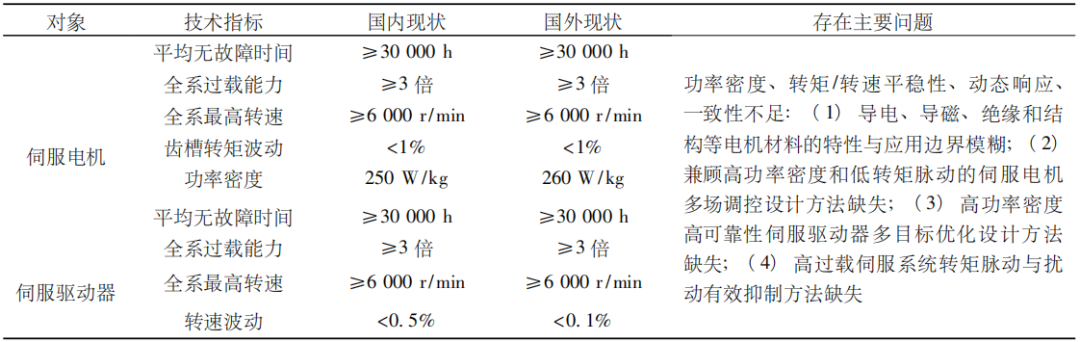

Since the 13th Five-Year Plan, research institutions represented by Hechuan Co., Ltd., Guangshu, and Huashu have driven rapid development in domestic servo systems. The entire series of X6 servo motors developed by Hechuan Co., Ltd. is nearing international advanced levels in performance indicators, with a maximum speed of 6000r/min, overload capacity exceeding three times, and torque ripple less than 1%; Guangshu’s servo controllers suppress high-frequency resonance above 100Hz through online parameter configuration using adaptive filters, with speed fluctuations less than 0.5%. However, domestic servo systems struggle to meet high-end market demands in terms of power density, torque/speed stability, and dynamic response, necessitating breakthroughs to establish international competitive advantages, as shown in Table 2.

Table 2 Comparison of Domestic and International Technical Indicators of Drivers and Servo Motors, Existing Issues

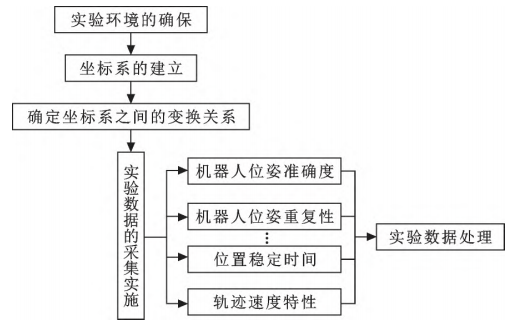

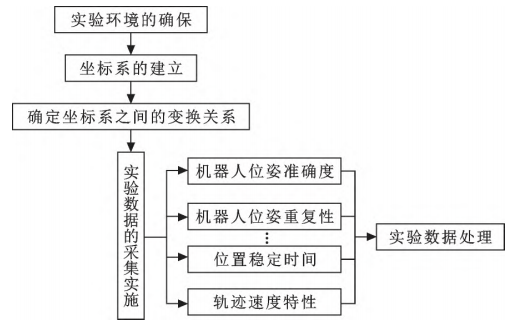

A more complete evaluation system has gradually become a barometer for competition in industrial robots. Japanese companies such as Nabtesco, Yaskawa, and Austria’s Keba have established strong technical barriers by conducting reliability and performance evaluations using corporate standards, with evaluation conditions and methods kept confidential, ensuring consistency and high reliability in mass production of products. Since the 13th Five-Year Plan, the National Evaluation Center (Chongqing Kairui Robot) has built a performance testing platform for core components, formulating and revising over 50 standards, accounting for over 60%, achieving a transition from “none” to “existence” in the performance testing technology system of core components in robots, accumulating a large amount of data. However, the existing system mainly references internationally accepted performance and safety standards, facing issues such as lengthy testing verification times, low precision in key technical parameter testing, underutilization of data mining, and insufficient high-level consistency evaluation methods, and has yet to form a technical and standard system that guarantees the evaluation of advanced core components. In light of this situation, Zhang Xi and others from Shanghai University invented a geometric accuracy evaluation software for robots, as shown in Figure 5, which improves the evaluation methods and standards for the geometric accuracy of robots.

Figure 5 Evaluation Process

Although the domestic evaluation system is continuously improving, extensive literature review reveals that the standardization of the domestic evaluation system still has many shortcomings.

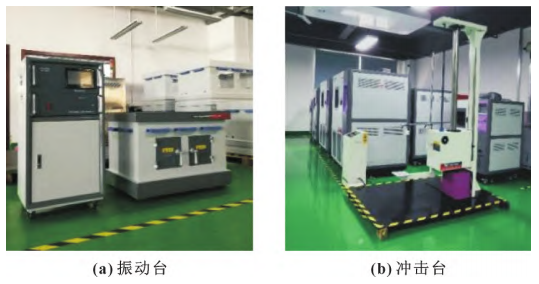

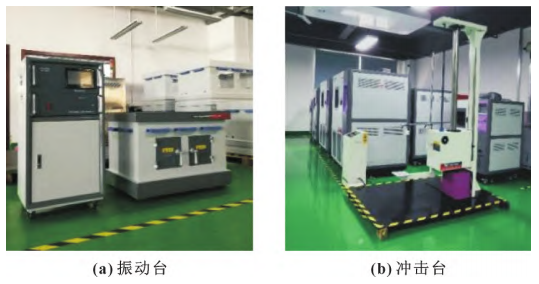

Currently, domestic standards such as ISO9283, JB/T8896, JB/T10825, and GB11291 have limited measurement conditions and cannot provide accurate optimization suggestions, as well as evaluations on the precision, economic, and environmental aspects of industrial robots. Meanwhile, foreign companies use internal standards, imposing technical barriers on domestic products to ensure high consistency and reliability. The detection standards for robots have received sufficient attention from the state, with the most authoritative being the national establishment of “four centers + two platforms,” namely the National Robot Testing and Evaluation Center and Public Service Platform. The equipment configured at these evaluation centers, such as environmental testing platforms, vibration tables (see Figure 6(a)), impact tables (see Figure 6(b)), and electromagnetic detection equipment, further fills the gaps in China’s evaluation system.

Figure 6 Equipment of the National Robot Testing Center

The robot industry is expected to exceed 500 billion yuan in revenue by 2025, marking a strategic opportunity for China’s robot industry to become self-reliant and leapfrog. Developing core components for robots that reach the advanced levels of similar international products, constructing a data-driven comprehensive performance evaluation digital twin platform for components, achieving integration of robot bodies and typical industry applications, and forming a high-level technology and standard system for components are of great significance for enhancing the international competitiveness of China’s robot core components, promoting the transformation and upgrading of the manufacturing industry, and building a strong intelligent manufacturing nation.

China’s developed robot core components still lag behind similar advanced international products. China must rapidly promote the application of high-end robots’ performance requirements for core components, break through the technical bottlenecks that restrict the performance and consistency improvement of core components, establish a benchmarking system with comprehensive indicators against top foreign brands, build a data-driven evaluation twin platform for components, and develop precision reducers, controllers, drivers, and servo systems for robots that reach the international advanced levels of similar products. This will enable integration and application promotion of robot bodies, enhance China’s international competitiveness in robotics, and seize the high ground in international competition.

To better serve the industry, the industrial robot editor has established a professional group for intelligent welding robots, mainly consisting of personnel from the automotive parts, shipbuilding, and steel structure industries. To join the group, one needs to sign up for the automotive, shipbuilding, or steel structure online meeting (registration is free). If interested, please add WeChat: 13810274816, show your business card, and indicate your interest in the meeting. Please note when joining other groups.

The original article was published in “Machine Tool and Hydraulic” in February 2024 by authors Zhao Ying, Wang Zhijie, Li Benwang, and Wu Zengping.

☞ Source: New Industrial Network ☞Editor: You Xiaoxiu☞Reviewer: Wang Ying

☞ Advertising Cooperation: Sun Ha 13811718902

Disclaimer: If there are copyright issues regarding the videos, images, or text used in this article, please notify us immediately. We will confirm the copyright based on the proof materials you provide and pay remuneration according to national standards or delete the content immediately!