Click the blue text to follow immediately

1. What is an Industrial Control System?

An industrial control system may sound abstract at first, but its task is quite concrete:real-time monitoring of production lines, ensuring precise operation of equipment, and stable data transmission.

For example

In an automotive manufacturing workshop, robotic arms can precisely weld car bodies, relying on the industrial control system to send commands in real-time; in a chemical plant, if temperature monitoring detects an anomaly, the system can instantly activate safety protections to prevent explosion risks.

In simple terms, if we compare a factory to a human body,the industrial control system is the brain and nervous system, with core components includingsensors, controllers, actuators, and human-machine interfaces, where the “brain-level devices” are the industrial computer and PLC.

2. PLC vs. Industrial Computer

Many people in the industrial control field cannot distinguish between PLCs and industrial computers (like the author in the early days  ), actually, their positioning is like “special forces” versus “all-round soldiers”, each with unique skills! Today, we will break it down in detail~

), actually, their positioning is like “special forces” versus “all-round soldiers”, each with unique skills! Today, we will break it down in detail~

1.Modular vs. General Purpose

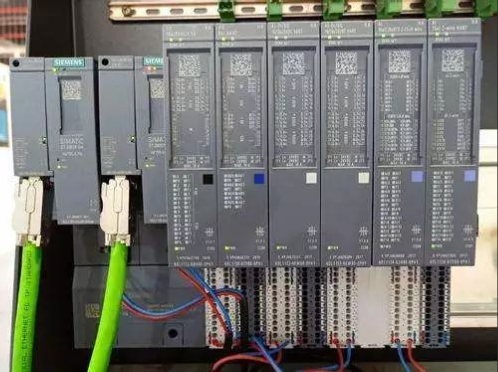

PLC: Like LEGO blocks, with a modular design (CPU, input/output modules, etc.), strong anti-interference capability, specifically designed for harsh environments, such as high-temperature workshops in steel mills, capable of withstanding high temperatures and dust.

Industrial Computer: Essentially a computer designed for industrial use, similar to commercial hosts, with CPU, memory, hard disk, and rich interfaces (USB, network ports, display interfaces, etc.), suitable for processing complex data.

2.Simple and Direct vs. Complex and Detailed

PLC: Good at“switch control”, such as the rise and fall of elevators, and the switching of traffic lights; it acts like a strict commander, only concerned with “whether to do it” and “when to do it”.

Industrial Computer: Capable of“data analysis + decision-making”, for example, a petroleum refining plant needs to analyze temperature and pressure data in real-time to optimize production parameters. It is more like a data analyst, providing optimal solutions after processing vast amounts of information.

3.Understandable by Electricians vs. Exclusive to Programmers

PLC: Programmed usingladder diagrams and instruction lists, similar to circuit diagrams, electricians can get started after a week of training, for example, controlling the start and stop of a conveyor motor can be accomplished with just a few lines of ladder diagram code.

Industrial Computer: SupportsC++, Python, and other high-level languages, suitable for developing complex algorithms, such as writing a visual inspection program in Python to detect scratches on smartphone screens.

4. Both are Durable!

If we talk about the commonality between the two, it is that both are designed for industrial-grade use, dustproof, waterproof, and shock-resistant, specifically built for industrial applications!

3. Practical Scenarios

PLC

1. Conveyor Control: In a beverage bottling line, the PLC controls the valve switches to ensure each bottle has the same capacity;

2. Equipment Safety Protection: If a CNC machine encounters abnormal vibrations, the PLC instantly cuts off power;

3. Simple Process Management: In an automatic parking lot, after license plate recognition, the PLC controls the barrier gate to lift.

Industrial Computer

1. Big Data Monitoring: Wind power plants use industrial computers to analyze wind speed and power generation, optimizing the angle of the wind turbines;

2. Visual Inspection: Electronics factories use industrial computers with cameras to inspect solder joints on circuit boards, achieving precision of 0.01 millimeters;

3. Intelligent Scheduling: Logistics centers use industrial computers to coordinate AGV vehicle paths, improving efficiency by 40%.

4. Collaborative Applications

In actual industrial production, industrial computers and PLCs are not mutually exclusive; they are often paired together, with the industrial computer making decisions (upper-level machine) and the PLC executing actions (lower-level machine).

For example, in a smart factory, the industrial computer analyzes order data and instructs the PLC to adjust the production line pace.

5. Industrial Control Systems in Daily Life

1. The subway signaling system is ensured by industrial control devices to prevent rear-end collisions;

2. Online shopping is shipped instantly because warehouse robots are directed by industrial control systems;

3. Wastewater treatment plants use PLCs to precisely control chemical dosing, reducing pollution.

6. Final Thoughts

It can be said that industrial control systems are the cornerstone of modern industry. After reading this article, I believe that when we marvel at the efficiency of “Made in China”, these “steel brains” will also come to mind~

Have you used or seen industrial control devices? Feel free to leave a comment for discussion!

ENDI appreciate every like and view!