Industrial robots are multi-joint mechanical arms or multi-degree-of-freedom machines widely used in the industrial field. They possess a certain degree of autonomy and can rely on their own power sources and control capabilities to achieve various industrial processing and manufacturing functions. Industrial robots are widely applied in various industrial fields such as electronics, logistics, and chemical industries.

01

Composition Of Industrial Robots

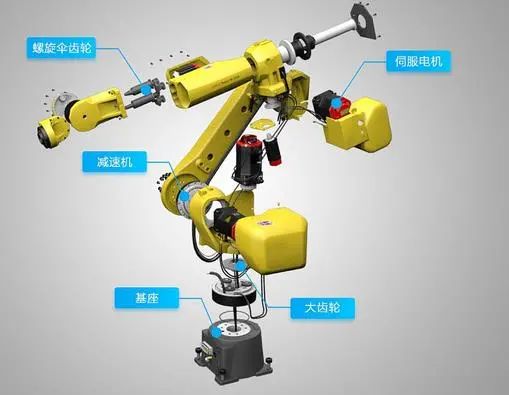

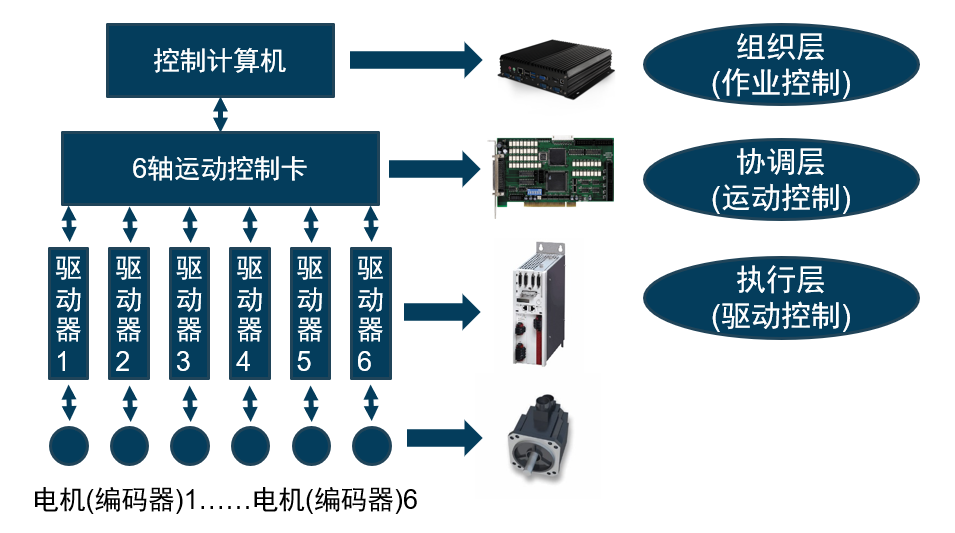

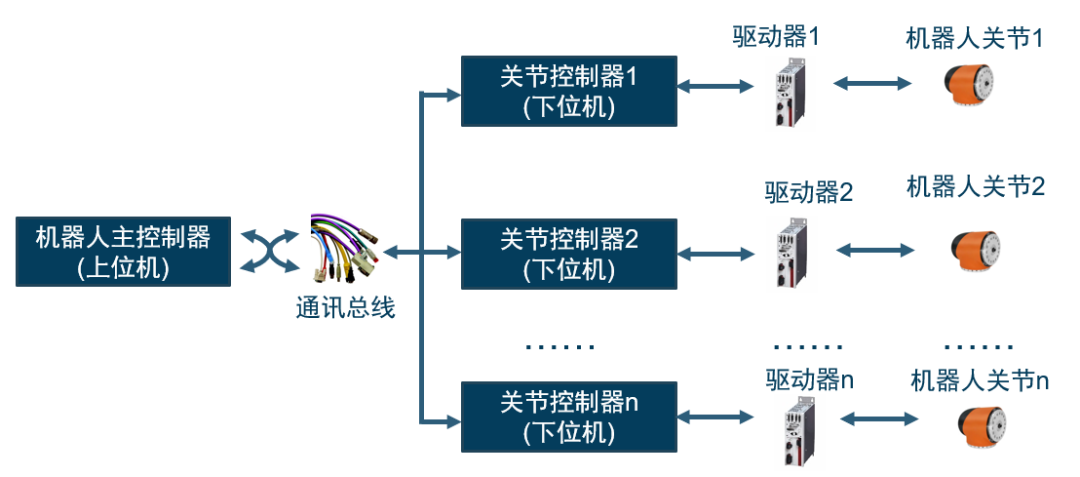

Industrial robots mainly consist of three basic parts: the body, drive system, and control system.

The body—consisting of the base and the actuating mechanism, includes the arm, wrist, and hand, and some robots also have locomotion mechanisms. Most industrial robots have 3 to 6 degrees of freedom, with the wrist typically having 1 to 3 degrees of freedom;

Drive system—comprising the power unit and transmission mechanism, with the core being the reducer and servo motor, used to enable the actuating mechanism to perform corresponding actions;

Control system—issues command signals to the drive system and actuating mechanism according to the input program and controls them.

02

Classification Of Industrial Robots

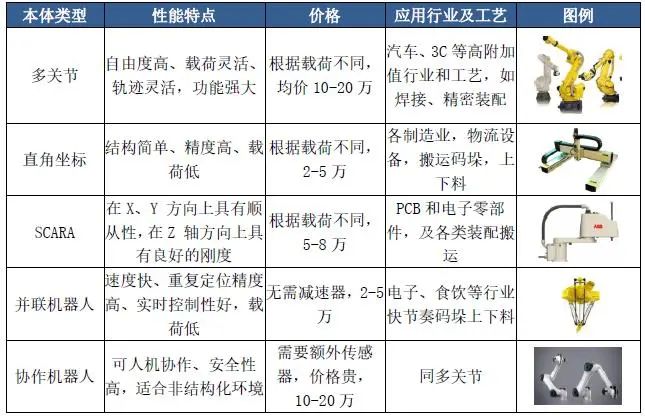

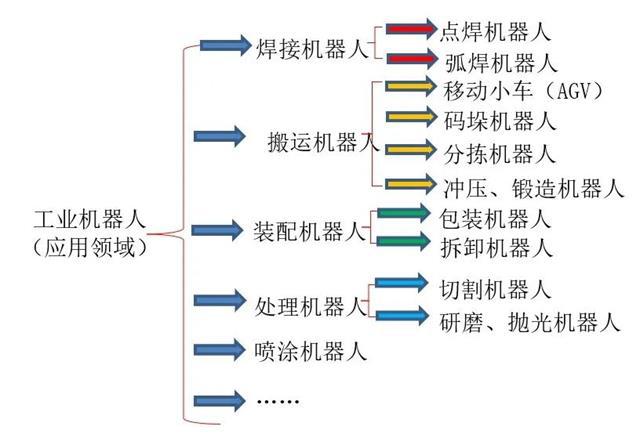

Regarding the classification of industrial robots, there is no unified standard designated internationally, and they can be classified according to load weight, control method, degrees of freedom, structure, and application fields.

03

Industrial Robot Industry Chain

04

Working Principles Of Industrial Robots

The working principle of robots is a relatively complex issue. Simply put, the principle of robots is to imitate various human limb movements, thinking patterns, and decision-making capabilities. From a control perspective, robots can achieve this goal through the following four methods.

“Teaching Playback” Method: It teaches the mechanical arm how to move through either a “teaching box” or “hand-in-hand” methods, the controller memorizes the teaching process, and then the robot repeats the taught actions in cycles, such as spray painting robots.

“Programmable Control” Method: Workers pre-write control programs based on the robot’s work tasks and motion trajectories, then input the control program into the robot’s controller, starting the control program, and the robot completes the actions step by step as specified by the program. If the task changes, the control program can be modified or rewritten, making it very flexible and convenient. Most industrial robots operate according to the first two methods.

“Remote Control” Method: Controlled by a person using a wired or wireless remote control to complete tasks in places that are difficult or dangerous for humans to reach, such as bomb disposal robots, military robots, and robots working in environments with nuclear radiation and chemical contamination.

“Autonomous Control” Method: This is the highest and most complex control method in robot control, requiring the robot to have the ability to recognize the environment and make autonomous decisions in complex unstructured environments, essentially exhibiting certain intelligent behaviors akin to humans.

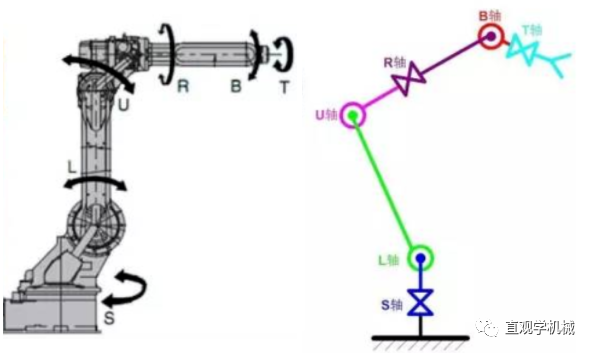

Taking a six-axis vertical multi-joint robot as an example (as shown below), through the robot controller and its control system, it can achieve S-axis rotation, L-axis lower arm tilt, U-axis upper arm tilt, R-axis arm lateral swing, B-axis wrist pitch, and T-axis wrist rotation, realizing the operation and coordination of six axes.

05

Challenges Faced By Industrial Robot Manufacturers

With the continuous industrial upgrading of the manufacturing industry and the emergence of various new technologies, robot manufacturers must also consider the usage needs of their end users during the production process. For example, when upgrading and transforming factories and production lines, robot manufacturers need to adapt to market changes and make corresponding adjustments.

To better serve the industry, we have established a professional group for intelligent welding robots. Add WeChat: 13810274816, show your business card, only for companies related to the robot and intelligent manufacturing industry chain.

☞Source: Intuitive Learning Mechanics ☞Editor: You Xiaoxiu☞Reviewer: Wang Ying

☞Advertising Cooperation: Sun Ha 13811718902

Statement: If the videos, images, or texts used in this article involve copyright issues, please inform us immediately, and we will confirm the copyright based on the proof materials you provide and pay remuneration according to national standards or immediately delete the content!

Statement: If the videos, images, or texts used in this article involve copyright issues, please inform us immediately, and we will confirm the copyright based on the proof materials you provide and pay remuneration according to national standards or immediately delete the content!