Click on the arrow to follow us!

When the S7-1200 acts as a DP Master, if the DP slave is lost, the CPU will not stop, and there is no need to download the organization block to the CPU. For fault diagnosis of PROFIBUS DP, the following methods are available:

1. Through the indicator lights on the module

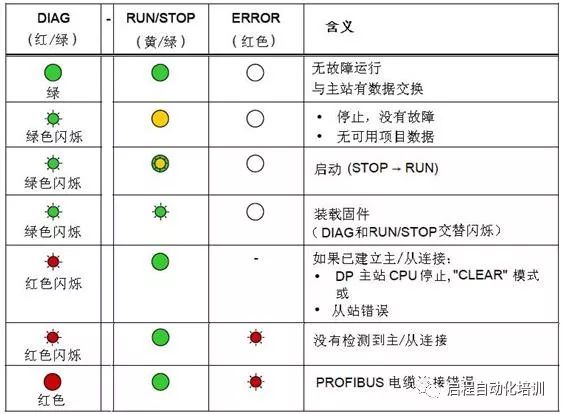

The DIAG light on the front panel is green when normal and turns red when there are errors or issues. The combination of the RUN/STOP, ERROR lights on the back cover, and the DIAG light on the front panel provides the module status:

Figure 1. Fault indicator lights for early CM1243-5 firmware versions V1.0 & V1.1

Figure 2. Fault indicator lights for CM1243-5 firmware versions V1.2 & V1.3

2. Diagnosis through programming software

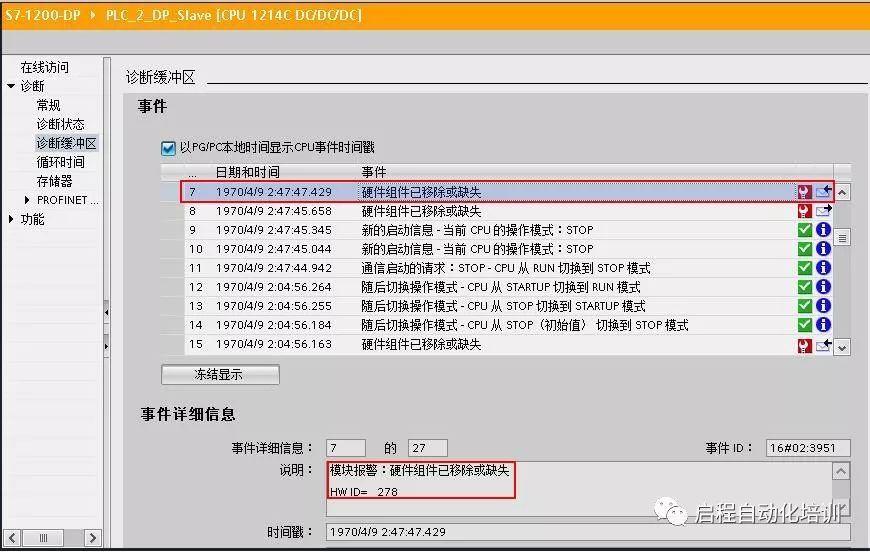

For early CM1243-5 firmware versions V1.0 & V1.1, check the entries in the CPU diagnostic buffer in STEP 7 V11.

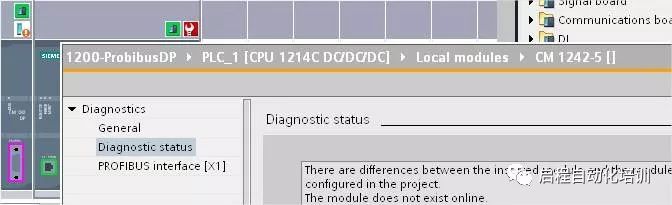

Check the online status of the module information

For newer versions of CM1243-5, such as version V1.3, view the diagnostic buffer for information on lost slaves in TIA V13 SP1:

3. Reading DP slave diagnostic information through the program

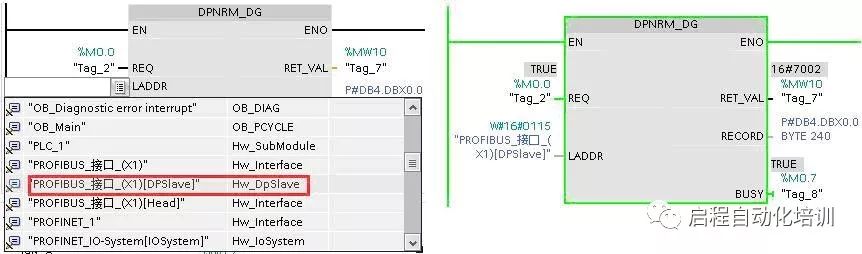

CM1243-5 uses the DPNRM_DG instruction to read diagnostic data from the PROFIBUS DP slave. DPNRM_DG instruction parameters:

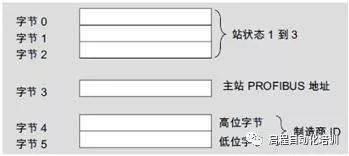

REQ: Read request LADDR: Slave diagnostic address RECORD: Target address for the read diagnostic data RET_VAL: Error code returned when the instruction fails BUSY: Reading diagnostic data CM 1242-5 supports 6 bytes of standard diagnostics and 6 bytes of device-specific diagnostics. The standard diagnostics can provide the status of the slave.

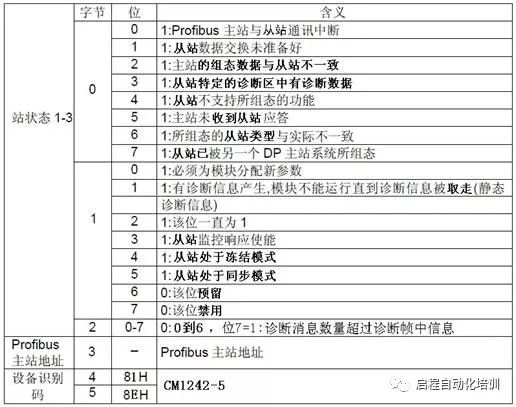

Overview of standard diagnostic data:

Standard diagnostic data information:

Method for reading standard diagnostic data:

In the main program OB1, call the S7-1200 “Extended Instructions/Distributed I/O/Others” DPNRM_DG instruction. Click on the block parameter LADDR, select the DP slave diagnostic address from the dropdown list, and the read diagnostic data will be stored in DB4.

View diagnostic data through monitoring tables:

About Us: Qicheng Automation Training, China’s leading industrial robot training service provider

Contact Number: 13809869603

Training Projects:Robot + PLC System Integration + Machine Vision

Training Method:Offline Practical Training

Special Services: 3000 square meter practical training center + job recommendations + industry-leading curriculum system

Address: Shajing, Bao’an District, Shenzhen, 107 Huiju Chuangzhi Park

+Teacher WeChat, learn more about the course details