This article employs a simple fiber laser direct writing (fLDW) process to produce flexible graphene sensors embedded with MO nanoparticles. fLDW is an integration of various printing processes into a single step. This singular process effectively synthesizes graphene, optimizes the properties of carbon structures through functionalization, enables doping and hybridization, and deposits metal oxide nanoparticles. Variations in laser writing parameters can alter the LIG surface, its functional group concentration, and the concentration of MO nanoparticles, thereby enhancing or hindering the electrical and photoelectric properties of the LIG/MOx sensors. Consequently, the manufactured LIG/MOx sensors exhibit excellent controllability in terms of selectivity, response time, recovery time, reproducibility, and stability.

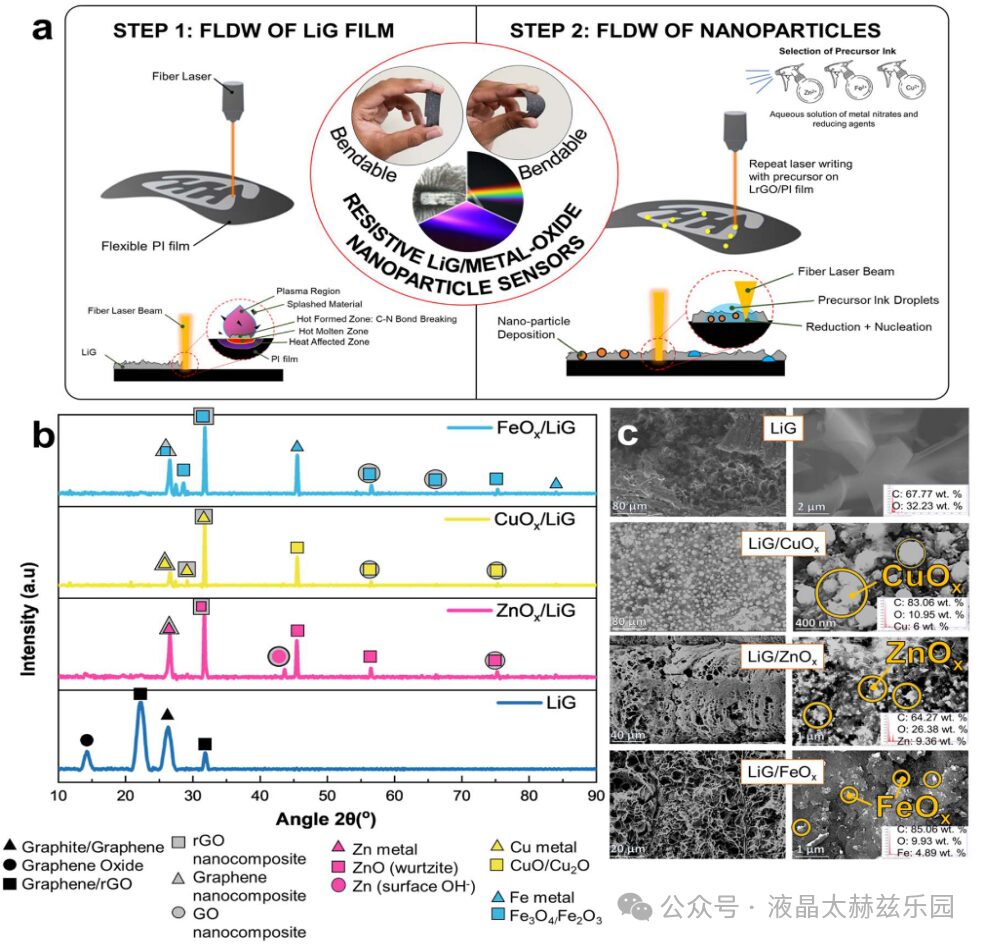

Figure 1a illustrates the fabrication procedure for flexible LIG/MOx nanoparticle sensors on a polyimide (PI) substrate. First, the PI film is irradiated/ablated with a laser to generate a porous LIG film. The newly released carbon atoms then rearrange to form a graphene structure or gas. Additionally, fLDW in ambient atmosphere can introduce oxygen functional groups onto the induced graphene structure. Next, precursor ink is sprayed onto the newly formed LIG film, followed by another round of laser scanning to deposit CuOx, FeOx, and ZnOx nanoparticles. The composition of the metal/metal oxide deposits can be altered by changing the laser processing parameters. XRD analysis in Figure 1b shows the structural characteristics of the LIG film. The XRD spectrum of the LIG/MOx film shows a significant absence of the characteristic peak of graphene oxide at 2q=14°, replaced by sharper peaks of graphite and rGO oxides, particularly a sharper peak for graphene oxide corresponding to the peak at 2q=32°. Generally, the higher intensity of the 32° peak indicates a fully graphitized system. This observation suggests that during the initial laser pass, fLDW primarily deposits GO, which after a second pass undergoes processing to form rGO/Gr in reaction with the metal ions in the precursor ink. Therefore, fLDW can deposit various forms of graphite, graphene, graphite oxide, and graphene oxide.

Figure 1.(a) The manufacturing mechanism and schematic of the LIG/MOx sensor with fLDW. (b) XRD spectrum analysis of the LIG/MOx film and (c) SEM images along with EDS results.

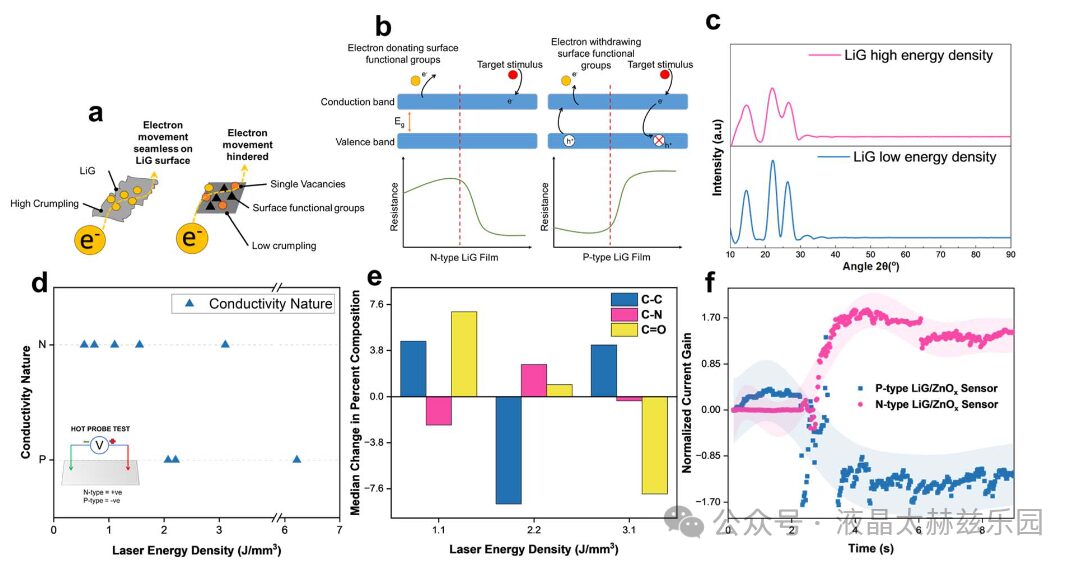

The fLDW process can produce sensors with customized responses to external stimuli by guiding the electron movement on the rGO sheets, as shown in Figure 2a. In the LIG/MOx sensors, the response is determined by the conductive properties of the LIG film, which in turn affects the overall sensing behavior. The XRD spectrum indicates that an increase in laser energy leads to a decrease in the crystallinity of the LIG film. In Figure 2c, the LIG film shows prominent peaks of graphene oxide at approximately 14° and 22° (d=0.822 and 0.432 nm) at low energy. Conversely, as the laser energy density increases during the manufacturing process, these GO peaks become broader. Both films display a graphite peak at 26.6° (d=0.335 nm), although less prominent at higher laser energies. The broader and smoother peaks suggest the presence of more amorphous structures. GO initially exhibits n-type conductivity, which is converted to p-type rGO by reducing the oxygen functional groups, thereby inducing p-type conductivity. To evaluate the efficacy of fLDW in printing n-type and p-type LIG films, thermal probe tests were conducted on samples produced at different laser energy densities. Below 2 J mm−3, the process primarily deposits n-type films; while between 2 to 2.5 J mm−3, the LIG exhibits p-type characteristics. The conductivity properties can be controlled by changing the laser energy density, as shown in Figure 2d.

Figure 2.(a) Schematic of electronic transport modification in the LIG film. (b) Sensing mechanism of p-type and n-type LIG with metal oxides. (c) XRD spectra of GO and rGO films produced by fLDW. (d) Relationship between laser energy density and the conductivity properties of induced LIG films. (e) Relationship between laser energy density and functional group changes, data from XPS C 1s scan. (f) Time and normalized current gain of p-type and n-type LIG/ZnOx samples under 1 V bias and UV stimulation.

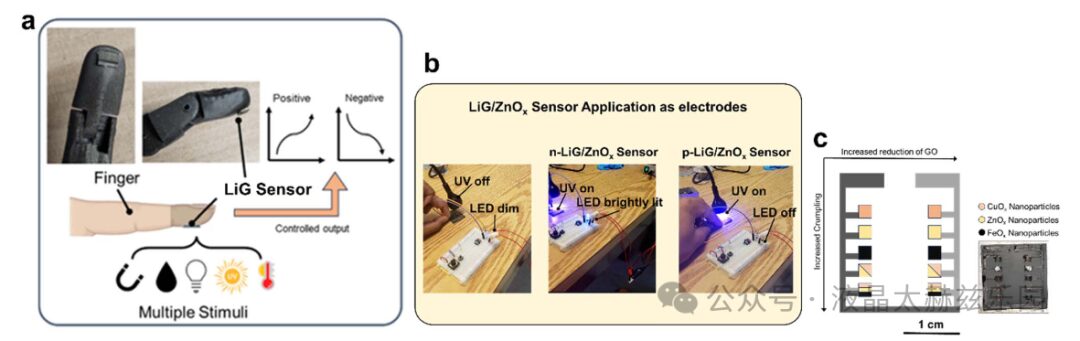

The LIG/MOx sensors are specifically designed for fingertip applications, as shown in Figure 3a. These sensors, based on PI films, can be profiled to meet the requirements of weight, flexibility, durability, multiple deformations, stretching, twisting, bending, and compression of biological entities. Figure 3b showcases the effective applicability of the LIG/MOx film as a laser-processed electrode. In the series circuit with LIG/ZnOx as the electrode, the adjustable current gain under UV light is evident. For the n-type LIG/ZnOx film, when subjected to a UV light stimulus of 1.085 W m−2, the resistance of the sensor decreases. As a result, the LED in the circuit increases in brightness due to higher conductivity. Conversely, when the p-type LIG/ZnOx is exposed to the same UV light, the resistance of the sensor increases, lowering the current enough to turn off the LED light. Finally, Figure 3c presents a proof-of-concept sensor grid that integrates all three metal oxides to highlight the multifunctionality and tunability of fLDW. The LIG layer mimics the electrodes, and the positions of the positive and negative terminals will alter the electronic transport through the sensor.

Figure 3. Demonstrations of different sensors. (a) Schematic of LIG/MOx sensor application on a robotic finger. (b) Used as an electrode for LIG/ZnOx sensors. (c) Schematic and photo of a multifunctional LIG/MOx sensor grid.

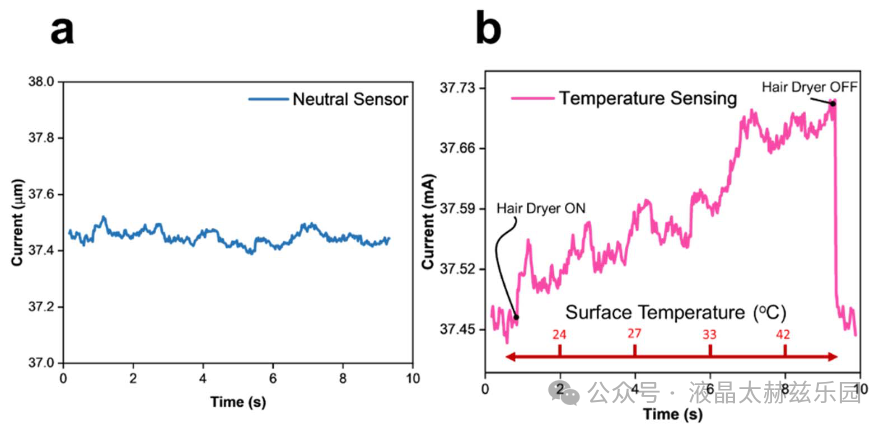

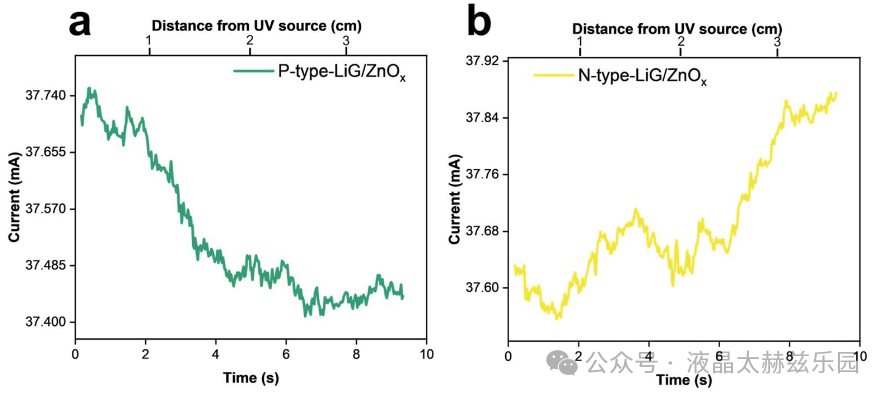

Figure 4a provides the current output of an LIG sensor without metal/metal oxide nanoparticles under a 1 V bias. Over time, the current output exhibits slight oscillations without any stimulation. The conductivity of LIG steadily increases with rising temperature, as shown in Figure 4b. Due to the density of states (DoS) near the Fermi energy, graphene films possess inherent temperature sensitivity, allowing the LIG sensor to respond to temperature changes. The temperature gradient adds electrons or holes to the graphene channel, resulting in increased conductivity, highlighting the advantages of the LIG/MOx sensor and its excellent tunability. The p-type LIG/ZnOx and n-type LIG/ZnOx sensors are connected to a robotic finger. The sensor’s response is measured at different distances from a UV light source with an intensity of 1.085 W m−2. fLDW emphasizes the stability of sensor manufacturing, as both sensors exhibit consistent resistance gradients, as shown in Figure 10.

Figure 9.(a) LIG sensor under 1 V bias without stimulation. (b) Temperature response of the LIG sensor.

Figure 10.(a) UV response of p-type and (b) n-type LIG/ZnOx sensors.

https://doi.org/ 10.5281/zenodo.14299824.

Source: Graphene Alliance