1. What are the differences between PROFIBUS and PROFINET? Do they have independent interfaces?

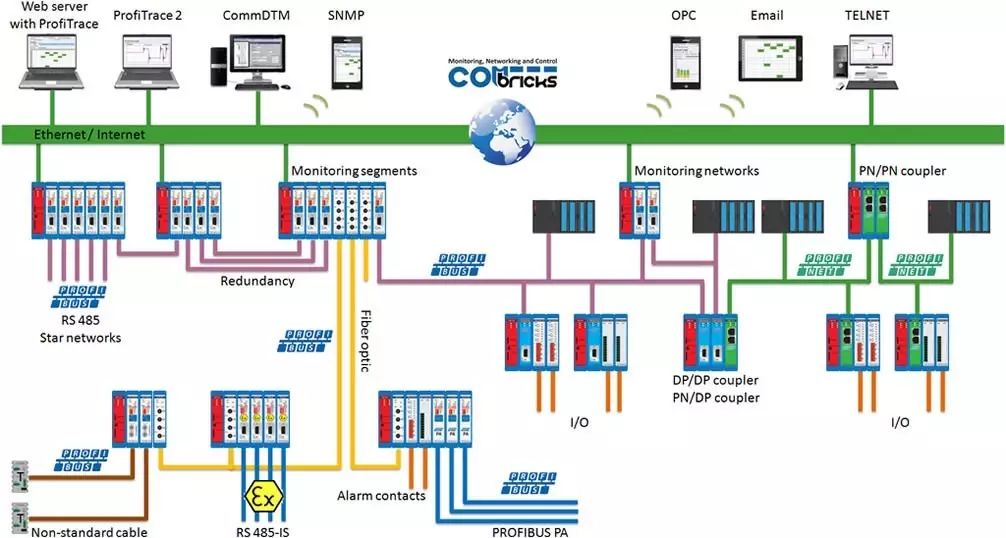

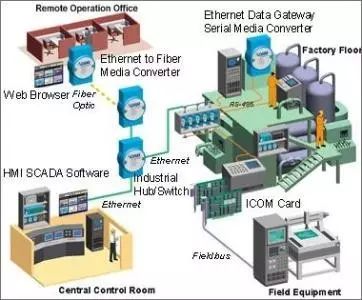

PROFIBUS is a fieldbus based on a communication system. PROFINET is an Ethernet-based communication system that provides a simpler way to integrate automatic control systems into large corporate IT systems, such as MES (Manufacturing Execution System) or ERP (Enterprise Resource Planning). Automatic control system vendors provide interfaces for both PROFIBUS and PROFINET. 2. How can equipment manufacturers (i.e., field instruments) develop their devices to meet the bus technology requirements of PROFIBUS? How can they obtain relevant technical materials and support? Answer: The PROFIBUS International Organization has established global PROFIBUS consulting centers. You can find a complete list at www.profibus.com->support->Competence Centers. There is also one in Beijing. The PROFIBUS consulting center provides support for equipment development, familiar with PROFIBUS requirements, particularly the certification process. 3. If a PROFIBUS DP slave is developed, is there any testing software (conformance testing) or testing tools available?

Answer: The PROFIBUS testing laboratory has developed its own testing software. Please contact the testing laboratory. 4. What is the difference between GSD files and DTM? Answer: GSD describes the technical parameters of the device. It meets industrial needs accurately. DTM is more powerful and flexible. It is a very good method for controlling existing systems and branching out later. 5. What measures are in place to ensure that the system does not suffer fatal damage due to errors during real-time configuration changes? Answer: When downloading a new configuration, everyone knows what they are doing. It is acknowledged that the actual process may not work for several seconds. 6. What types of support chips does Siemens provide for users engaged in designing PROFIBUS masters or slaves? Please describe the characteristics and suitability of each type of chip. Where can these be obtained (purchased) in China?

Answer (Siemens): To purchase PROFIBUS ASICs, please contact your local Siemens office in China. Technical issues can be resolved through the PROFIBUS support center in Germany.

7. Currently, “building automation” is also a trend. Has the promotion and application of fieldbus in this area been considered?

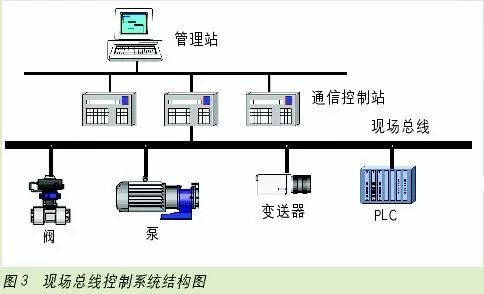

Answer: PROFIBUS is mainly used in factory and process industries. It can also be used for building automation. The key issue is that the device optimizes building automation, which mainly has widely used interfaces for this branch of bus systems (e.g., European Installation Bus (EIB), Local Operating Network (LON), BACnet). 8. Is there any similarity between configuration software, such as STEP7, and asset management software? What are the differences?

Answer (Siemens): S7, STEP7, and PCS7 are Siemens brands. S7 supports a complete automatic control system. STEP7 supports automatic control software (programming, configuration, etc.).

PCS7 supports DCS systems and includes configurations from S7, particularly STEP7. Asset management functions (PAM) are integrated into PCS7. 9. Where can the PROFIBUS protocol and standards be obtained? Answer: Typically, only product system suppliers and testing laboratories need the PROFIBUS protocol and specifications. The PROFIBUS standards can be obtained through IEC or national standardization organizations. In addition to this literature, documents like “PROFIBUS Quick Start” are also sufficiently available.

10. When discussing the usage of fieldbus, it is said that certain buses, such as PROFIBUS and Interbus, have installed over 20 million nodes. What does “node” refer to here? Does this mean they are applied in related production fields?

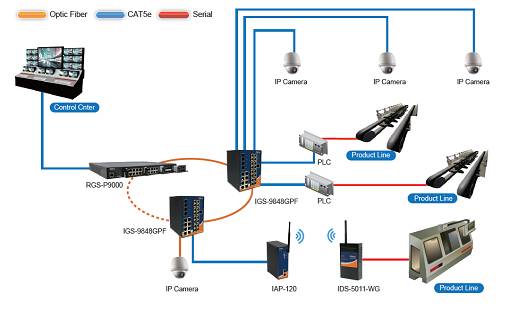

Answer: The term “node” refers to “the number of devices” rather than I/O points. Only PROFIBUS can be applied in factory automation and process automation. Approximately 2.1 million PROFIBUS nodes have been installed for process automation applications. 11. How does PROFIBUS-PA address redundancy issues? Answer: PROFIBUS has a redundancy concept where a slave device has two physical bus interfaces. These two bus interfaces can connect to the master via a single bus cable (slave redundancy), connect to two masters (initial master and backup master) via a single bus cable (slave redundancy and master redundancy, also known as temporary redundancy), or connect to two masters via two independent bus cables (system redundancy). This concept applies only to RS485 interfaces as the physical layer. PROFIBUS PA typically operates with Manchester Bus Power (MBP), generating power through the bus cable to drive devices, so there are no redundant slaves with two bus interfaces. Therefore, two independent slaves of the same type can be used in PROFIBUS PA. This concept applies based on DCS’s a), b), or c) methods. 12. Can power system products use PROFIBUS? Answer: Yes. Please refer to the ARC white paper “Value Proposition of PROFIBUS in the Process Industry,” page 12: “Italy uses PROFIBUS for power plant repairs.”

13. In terms of development trends, have advanced process control algorithms (APC) been embedded in DCS field control stations (such as Emerson’s Delta V), and do SIEMENS and ABB’s DCS now offer similar technologies?Answer (Siemens): Since version 5.0 (2001), Siemens DCS Simatic PCS7 has been able to use advanced process control algorithms (APC). 15. If the APC algorithm is embedded in the DCS control station, then if the basic control algorithms (PID, etc.) can be embedded in field devices with fieldbus, it would greatly enhance the control and optimization capabilities of the control station. FF currently has the capability to embed PID function blocks in field devices, but PROFIBUS-PA does not have such functionality. Will PROFIBUS-PA address this issue in the future? Answer (Siemens): There is no need for the control station to use PROFIBUS PA; the performance of the fieldbus is sufficient and continuously enhanced to ensure the effectiveness of redundant automatic control.

Source: Industrial Control Forum PROFINET, infringement deleted

Link: How to Become an Industrial Robot Application Engineer?

We are not just transporters of dry goods

Only a follow away from becoming an industrial robot master

Guide Car Robot Academy, cradle of robotic craftsmen

< Previous Classic Articles >

-

Foxconn Automation Production Line Video, a visual feast!

-

Huawei Automation Production Line, shocking!

-

Automated Conveyor Belt, so advanced!

-

What does the future intelligent workshop of a steel factory look like?

-

Fully automated cigarette production line, amazing!

-

Various sensor working principles animated graphics, informative!

-

10 workers + 386 robots, producing 80 Cadillacs daily!

-

Automated chicken and pig slaughtering is nothing, come see automated fish slaughtering!

-

The five major misconceptions in factory automation renovation, do not touch!