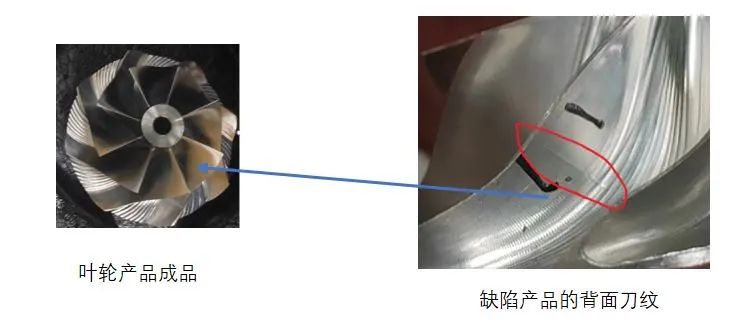

A customer of Siemens 840DSL processes impeller products, with loading and unloading performed by a third-party robot. Quality inspection personnel found through multiple random checks that: for every 500 products processed, about 10 products have the following quality issue: there is a noticeable knife mark on the back of the blades. When operators performed manual loading and unloading, the above issue did not occur.

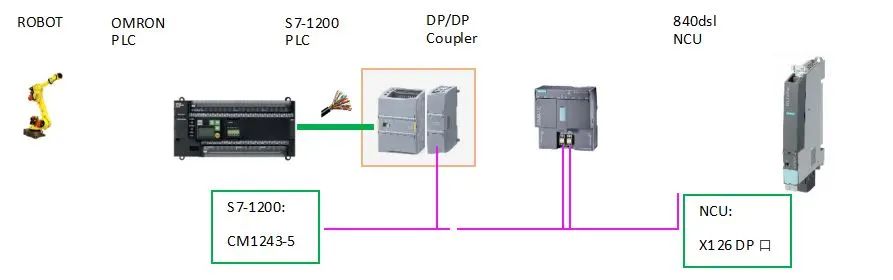

Since this product quality issue only occurred when using the robot for loading and unloading, we investigated the signals exchanged between the robot and the machine tool and determined that the Profibus configuration would be key to solving the problem.

* Main interaction signals between the robot and the machine tool

– Life signs of the fieldbus

– Release/Clamp fixture

– Loading device ready

– Loading device protection closed

– Loading termination

– Flushing activated

* Signal flow direction between the robot and the machine tool

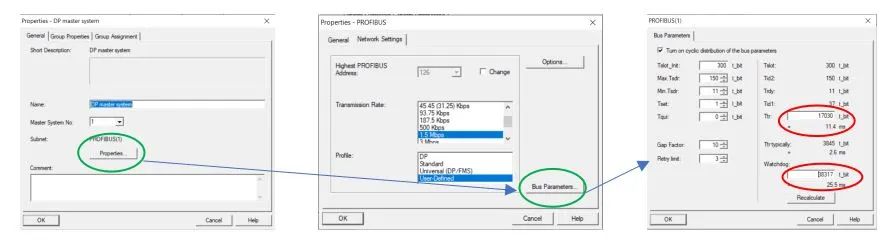

1. Inspection of Profibus Configuration

01

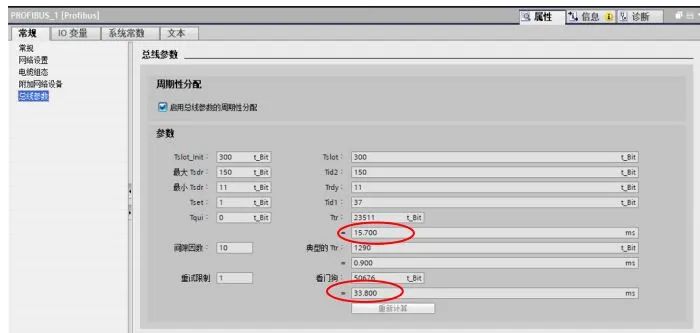

Bus configuration on the 840DSL system side

The Profibus on this side uses a user-defined type, with a signal transmission baud rate of 1.5Mbps.

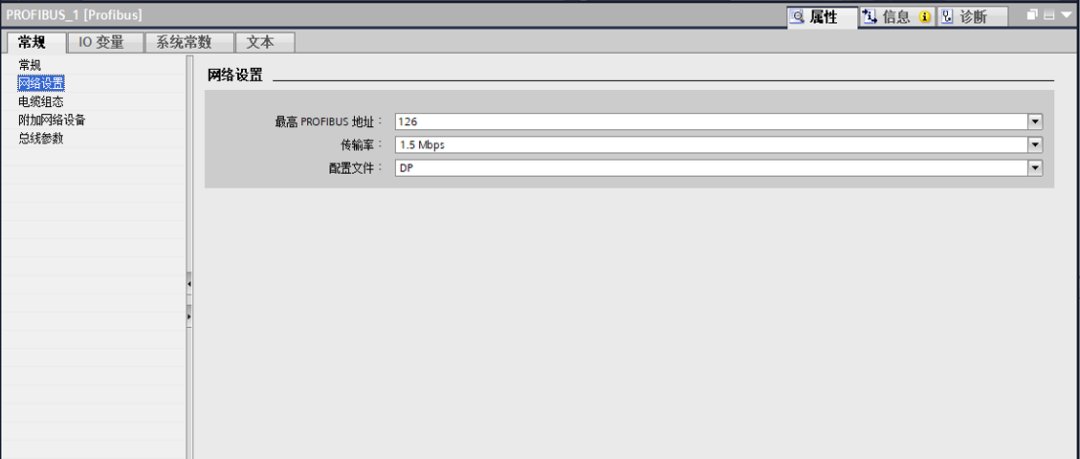

02

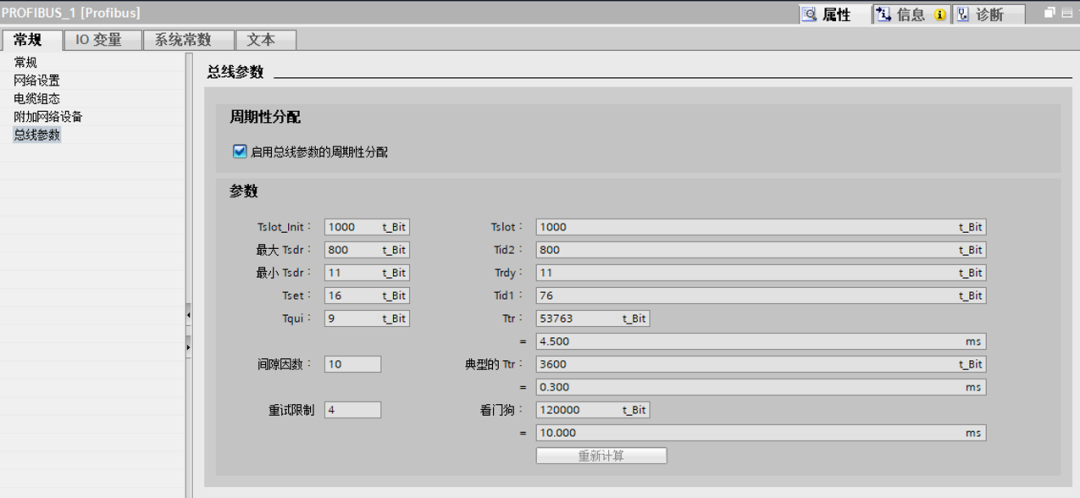

Bus configuration of the robot side PLC S7-1200

The Profibus on this side uses the standard DP type, with a signal transmission baud rate of 1.5Mbps.

From the above configuration information, we can see that the communication cycle on the robot side is greater than that on the system side, which means that the signals on the robot side lag behind those on the system side, indicating a possible abnormality in the life signs of the fieldbus, which could cause the system to momentarily stall and affect product processing on the system side.

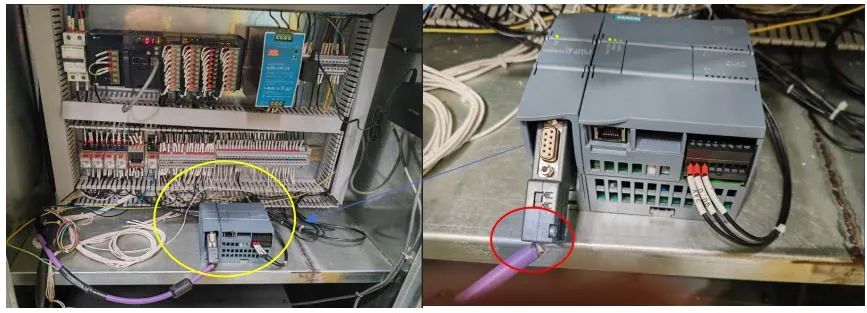

2. Inspection of Profibus Connections

Improper bus connections can also cause abnormalities in the life signs of the fieldbus. The following image shows improper wiring of the PROFIBUS, with the shielding layer not pressed into the DP head.

3. Countermeasures

Reconnect all PROFIBUS connectors according to specifications, and ensure equipotential checks and grounding protection measures are in place.

Reconfigure the fieldbus on the robot side S7-1200 to ensure that the communication cycle on the robot side is less than that on the system side, for example, by increasing the bus communication rate to 12Mbps.

After the above inspections and adjustments, the product was processed continuously for a week without any recurrence of the same quality issue.

Click the card to share your CNC machine usage experiences and tips with us.