EtherCAT, with its high speed, real-time performance, and high precision, has become the preferred communication protocol for control systems in the field of industrial automation. However, its strict dependence on network quality and device configuration means that once anomalies occur, the difficulty and time cost of troubleshooting and repair can significantly increase. Achieving more efficient and visualized EtherCAT network debugging and maintenance has become a common challenge faced by field engineers.

01

Analysis of EtherCAT Frame Structure:

The Core Foundation of Diagnostic Capability

The core of EtherCAT lies in its unique frame structure— data sent by the master station passes through all slave stations in a topological order, with each slave only needing to perform its own data read and write operations before forwarding the frame to the next node. This ‘frame penetration’ mechanism allows the master station to complete the entire data exchange process within a single frame, and any communication anomaly from a slave station can be instantly captured through frame analysis.

Typical fault modes include abnormal frame data length, command execution failures, and sudden increases in error counters, all of which can be accurately identified using frame-level diagnostic tools. Especially in environments with strong interference, aging cables, or complex topologies, the visualization of the EtherCAT frame structure will become a key tool for problem localization.

02

The Pain Points in the Field:

Without Good Tools, Debugging is Like“Blind Men Touching an Elephant”

During actual deployment and maintenance, engineers often need to determine whether the problem originates from the physical layer (such as cables or connectors), from configuration errors, master station communication logic, or even from an abnormal response of a slave station. Traditional debugging methods often only reveal the results (such as unresponsive I/O) rather than the process data, making localization both time-consuming and labor-intensive.

If it were possible to view communication status, data consistency, and error distribution in real-time at the frame level, and compare it with the configuration file in real-time, debugging efficiency would be significantly improved, allowing engineers to truly achieve the maintenance goal of “one localization, one repair.”

03

Meitong Technology Brings Professional Diagnostic Tools:

Precise Localization, Rapid Response

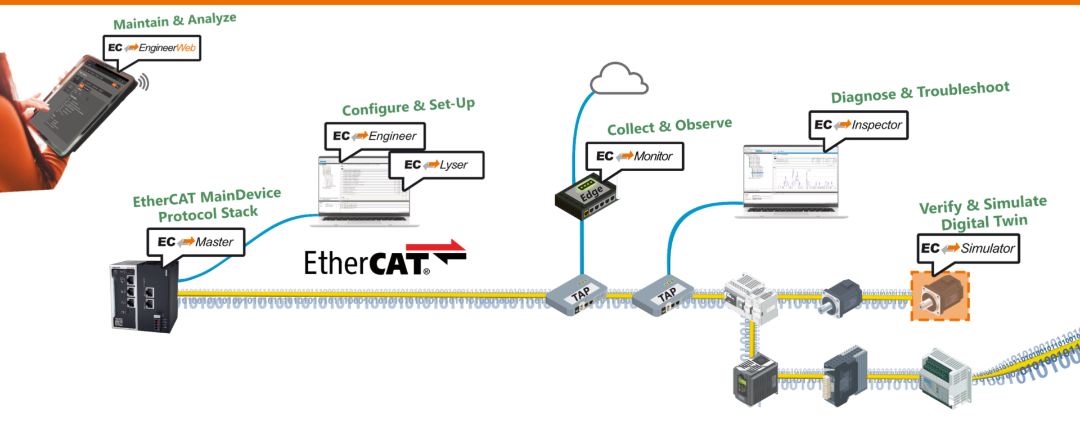

To address the above challenges, Meitong Technology’s partner acontis has launched several EtherCAT network diagnostic tools, while Meitong Technology provides localized technical support and services for customers:

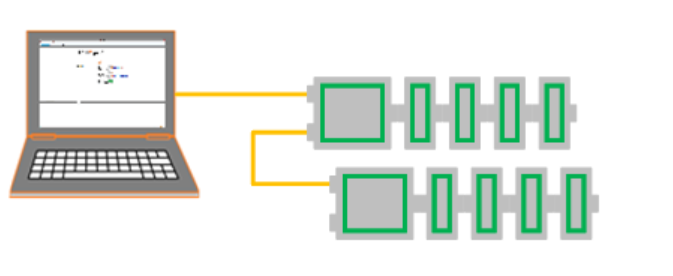

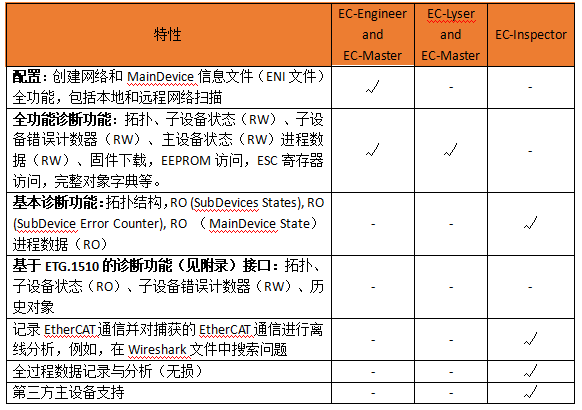

• EC-Engineer: A tool for the engineering phase that integrates configuration, debugging, and monitoring, suitable for slave station configuration and network testing.

• EC-Inspector: Operates independently of the master station, collecting complete frame data through a network TAP, supporting analysis in third-party master station environments.

• EC-Monitor: A library-level tool for developers that can be deeply integrated into customer applications to implement custom diagnostic logic.

• EC-Lyser: Quickly identifies startup failures, cable faults, or EMC interference, suitable for emergency and on-site troubleshooting.

These tools form a complete chain of “visualized diagnostics” for the EtherCAT network, from engineering configuration and operational monitoring to remote diagnostics, helping engineers to discover and resolve issues more quickly and accurately.

04

Conclusion:

Locating Problems in 30 Seconds and Leaving Work Two Hours Early is Not a Dream

The EtherCAT network is not an “invisible black box.” With the right tools and methods, every frame of data can be made “visible and understandable” from bits to devices. Meitong Technology is committed to bringing internationally leading EtherCAT diagnostic capabilities to local customers, alleviating engineers’ frustrations with difficult troubleshooting.

We welcome you to follow Meitong Technology for more practical EtherCAT experience and tool guides.