In recent years, sensors have been developing towards sensitivity, precision, adaptability, compactness, and intelligence. In this process, fiber optic sensors, a new member of the sensor family, have gained much favor. Fiber optics possess many excellent properties, such as resistance to electromagnetic interference and atomic radiation, fine diameter, soft texture, and lightweight mechanical properties; electrical insulation and non-inductive electrical properties; and chemical resistance to water, high temperatures, and corrosion. They can function in areas inaccessible to humans (such as high-temperature zones) or in harmful environments (such as nuclear radiation zones), acting as human ears and eyes, and can even surpass human physiological limits to receive external information that is imperceptible to human senses.

Basic Composition and Principle of Fiber Optic Sensors

Fiber optic sensors consist of a light source, incident fiber, outgoing fiber, optical modulator, photodetector, and demodulator. The basic principle is to send the light from the light source through the incident fiber into the modulation area, where the light interacts with the external measured parameters, causing changes in the optical properties of the light (such as intensity, wavelength, frequency, phase, polarization state, etc.), resulting in modulated signal light, which is then sent through the outgoing fiber to the photodetector and demodulator to obtain the measured parameters.

Fiber optic sensors can be divided into two categories based on their sensing principles: one type is the light transmission type (non-functional type) sensor, and the other is the sensing type (functional type) sensor. In light transmission type fiber optic sensors, the fiber only serves as a medium for light transmission, while the sensing of the measured signal is accomplished by other sensitive elements. In this type of sensor, the outgoing and incoming fibers are discontinuous, with the modulator between them being a sensitive element for spectral changes or other properties. In sensing type fiber optic sensors, the fiber serves both as a sensitive element for the measured signal and as a medium for light signal transmission, thus integrating the sensing and transmission functions, making the fiber continuous in this type of sensor.

Due to the different roles of the fiber in these two types of sensors, the requirements for the fiber also differ. In light transmission type sensors, the fiber only transmits light, and using communication fibers or even ordinary multimode fibers can meet the requirements, while sensitive elements can be flexibly selected from high-quality materials to achieve high sensitivity. However, this type of sensor requires more optical coupling devices and has a more complex structure. In contrast, sensing type fiber optic sensors have a relatively simple structure, requiring fewer coupling devices, but have higher requirements for the fiber, often needing special fibers that are sensitive to the measured signal and have good transmission characteristics. So far, most practical applications have adopted the former, but with improvements in fiber manufacturing technology, sensing type fiber optic sensors are expected to see widespread application.

Based on the different principles of light modulation in the fiber, fiber optic sensors can be classified into: intensity modulation type, phase modulation type, polarization state modulation type, frequency modulation type, wavelength modulation type, etc. To date, fiber optic sensors can measure over seventy physical quantities. Compared to traditional sensors, fiber optic sensors have unique advantages.

(1) High sensitivity. Since light is a form of electromagnetic wave with a very short wavelength, its optical length can be determined through the phase of light. For example, in a fiber optic interferometer, due to the small diameter of the fiber, when subjected to slight mechanical forces or temperature changes, its optical length changes, resulting in significant phase changes. Assuming a 10-meter fiber, a 1°C change causes a 1000 rad phase change; if the smallest detectable phase change is 0.01 rad, the minimum temperature change that can be measured is 10°C, demonstrating its high sensitivity.

(2) Resistance to electromagnetic interference, electrical insulation, corrosion resistance, and inherent safety. Since fiber optic sensors use light waves to transmit information, and the fiber itself is electrically insulated and corrosion-resistant, they can be conveniently and effectively used in various large electromechanical, petrochemical, and mining environments with strong electromagnetic interference and flammable or explosive conditions.

(3) Fast measurement speed. Light travels at the fastest speed and can transmit two-dimensional information, making it suitable for high-speed measurements. Analyzing signals from radars and other sources requires extremely high detection rates, which are difficult to achieve using electronic methods; however, high-speed spectral analysis using the diffraction phenomenon of light can solve this issue.

(4) Large information capacity. The measured signal is carried by light waves, and since light has a very high frequency, it can accommodate a wide bandwidth, allowing a single fiber to transmit multiple signals.

(5) Suitability for harsh environments. Fiber optics are dielectrics, resistant to high pressure, corrosion, and electromagnetic interference, making them suitable for harsh environments where other sensors may not function.

Additionally, fiber optic sensors are lightweight, compact, flexible, have a wide range of measurement objects, good reusability, and low cost. The application of fiber optic sensors is driven by their numerous advantages, leading to a wide range of applications in fields such as petrochemicals, electricity, medicine, and civil engineering.

1. Application of Fiber Optic Sensors in Petrochemical Systems. In petrochemical systems, the underground environment is characterized by high temperatures, high pressures, chemical corrosion, and strong electromagnetic interference, making it difficult for conventional sensors to perform well underground. However, fiber optics are non-conductive, small, lightweight, flexible, and resistant to electromagnetic interference and radiation, making them particularly suitable for use in flammable, explosive, space-constrained, and strong electromagnetic interference environments. Therefore, fiber optic sensors play an irreplaceable role in measuring oil well parameters and are expected to become a new technology with broad market prospects applicable to oil and gas exploration and petroleum logging.

1.1 Fiber Optic Sensors in Oil and Gas Exploration. Due to their resistance to high temperatures, multi-channel, and distributed sensing capabilities, as well as their requirement for minimal space, fiber optic sensors have unique advantages in exploration drilling.

By applying fiber optic sensors, downhole spectrometers, distributed temperature sensors, and fiber optic pressure sensors can be developed to meet the specific operational requirements.

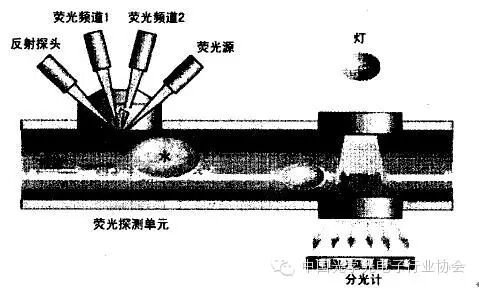

(1) Downhole Spectrometer Fluid Analyzer, as shown in Figure 1, can be used to understand the composition of crude oil during the initial development process. It consists of two sensors: one is an absorption spectrum fiber spectrometer, and the other is a fluorescence and gas detector. Downhole fluids are introduced through a formation probe into the production tubing, and the optical sensor is used to analyze the fluids inside the production tubing. The fluid analysis spectrometer provides in-situ downhole fluid analysis and improves the assessment of formation fluids.

(2) Distributed Temperature Sensors. Fiber optic distributed temperature sensors are the most popular fiber optic sensors used underground. An application example is monitoring steam injection in heavy oil extraction systems. Steam is injected into the heavy oil layer to reduce the viscosity of the oil, allowing for extraction. The downhole steam temperature can exceed 250°C.

Figure 1 Structure of Fluid Analyzer

(3) Pressure Sensors. Side-hole fiber optic pressure sensors are currently under development, primarily focused on ultra-high temperature and downhole pressure monitoring tasks. Other commercial products based on fiber optic sensors have emerged, such as fiber probes for multiphase flow measurement and distributed dynamic strain measurement. Their high reliability and efficient low-consumption technical advantages are key factors for the success of fiber optic products in oilfield applications.

1.2 Application of Fiber Optic Sensors in Petroleum Logging. Petroleum logging is one of the most fundamental and critical aspects of the petroleum industry. Parameters such as pressure, temperature, and flow rate are important physical quantities in oil and gas wells. Long-term real-time monitoring of these quantities through advanced technical means is of great significance for the petroleum industry. Fiber optic sensors are insensitive to electromagnetic interference and can withstand extreme conditions, including high temperatures, high pressures, and strong shocks and vibrations, allowing for high-precision measurement of borehole and wellsite environmental parameters. Additionally, fiber optic sensors have distributed measurement capabilities, enabling spatial distribution measurements and providing profile information. Moreover, fiber optic sensors have a small cross-sectional area and short form factor, occupying minimal space in the borehole. These characteristics are not possessed by traditional electronic sensors in harsh underground environments.

Using fiber optic sensors, downhole flow measurement, temperature measurement, pressure measurement, water (gas) content measurement, density measurement, and acoustic wave measurement can be performed.

(1) Flow Measurement. The intensity, phase, frequency, and wavelength characteristics of light are modulated by flow during fiber optic transmission. By using certain optical detection methods to convert the modulated quantities into electrical signals, the flow rate of the fluid can be determined, which is the working principle of fiber optic flow meters.

(2) Temperature and Pressure Measurement. Distributed fiber optic measurement systems (DTS) utilize the temperature effect of backscattered Raman scattering in fiber optics to monitor the temperature field where the fiber is located in real-time. EFPI type (non-intrinsic F-P interference) and FBG type fiber optic sensors are wavelength-coded sensors with high sensitivity and the ability to simultaneously measure multiple parameters such as pressure, temperature, and stress. Fiber optic thermal color temperature sensors consist of a white light source and multimode fiber; fiber optic radiation temperature sensors utilize black body radiation energy, are non-contact, can measure instantaneous temperatures, have fast response times, and do not require thermal equilibrium time, making them suitable for high-temperature measurements. Semiconductor absorption fiber optic temperature sensors utilize the characteristic that the absorption edge wavelength of semiconductor materials shifts to longer wavelengths with increasing temperature, selecting appropriate semiconductor light-emitting diodes so that their spectral range falls within the absorption edge region, thus the intensity of light passing through the semiconductor decreases with increasing temperature.

(3) Water (Gas) Content and Density Measurement. The transmission power of U-shaped fibers changes with the refractive index of the external medium. Light waves, as information carriers, are independent of the resistivity, flow type, and water quality of mixed fluids. Based on this principle, fiber optic content/density sensors fundamentally solve the existing issues of high water content with no resolution and the application of radioactive materials. The refractive indices of multiphase fluid oil, water, and gas are different, so the refractive index of mixed fluids changes with the oil, water, and gas ratios. Therefore, this type of refractive index modulation fiber optic sensor can not only measure fluid content but also measure fluid density with high accuracy.

(4) Acoustic Wave Measurement. Seismic waves propagate differently in various media, resulting in different waveforms received. Based on different seismic waveforms, sedimentary sequences and sedimentary structures can be identified, aiding in reservoir location, fault detection, casing damage detection, perforation layer positioning, and fluid flow determination. VSP seismic logging involves placing detectors in the well to receive seismic signals generated by ground-initiated seismic waves or micro-vibrations caused by fluid flow in the well. Permanent downhole fiber optic three-component seismic measurement has high sensitivity and directionality, producing high-precision spatial images, providing not only near-well images but also images of surrounding formations, with measurement ranges reaching several kilometers. It can withstand harsh environmental conditions, has no movable parts or downhole electronic devices, can endure strong shocks and vibrations, and can be installed in the small spaces of complex completion tubing. Fiber optic sensors in power systems.

The network structure of power systems is complex and widely distributed, with various hidden dangers existing in high-voltage power lines and power communication networks. Therefore, distributed monitoring of various lines and networks within the system is particularly important.

1. Application in High Voltage Cable Temperature and Strain Measurement. Currently, abroad (mainly in the UK, Japan, etc.), distributed fiber optic temperature sensor products have been developed using laser Raman spectral effects. Domestic research in this area is also actively underway. The introduction of distributed fiber optic temperature sensing technology into the research of temperature measurement for power system cables in China has only just begun. Considering the snow disaster that southern China experienced last year, if sensing cables could be laid parallel to high-voltage cables to measure temperature, pressure, and other parameters of power system cables and towers in real-time, it would enable timely risk mitigation, thus minimizing economic losses. It is evident that fiber optic sensors will have broad application prospects in power systems. Ideally, the fiber should be placed as close to the cable core as possible to measure the actual temperature of the cable more accurately. For direct-buried power cables, although surface-mounted fibers cannot accurately reflect changes in cable load, they are sensitive to changes in soil thermal resistivity where the cable is buried, and can reduce the installation costs of the fiber.

2. Application in Electric Power Sensors. Electric power is a fundamental quantity reflecting energy conversion and transmission in power systems, and electric power measurement is an important aspect of power metering. With the rapid development of the power industry, traditional electromagnetic measurement methods have increasingly revealed their inherent limitations, such as electrical insulation, electromagnetic interference, and magnetic saturation issues. Therefore, efforts have been made to find new methods for measuring electric power. The emergence of fiber optic sensors has brought good news for solving this problem. The main characteristics of fiber optic electric power sensors are that since electric power measurement involves both voltage and current, it usually requires consideration of both electro-optic and magneto-optic effects, often utilizing two sensing media or one multifunctional medium as sensitive elements, which makes the structure of fiber optic electric power sensors relatively complex. Additionally, the optical sensing signals of fiber optic electric power sensors sometimes contain both voltage and current signals, making their signal detection and processing methods more complex.

3. Application in Monitoring Optical Cables in Power Systems. There are various types of optical cables in power systems, and due to the vast territory of China and significant environmental differences, the environments for optical cables are also complex. Among them, temperature and stress are the main environmental factors affecting the performance of optical cables. Therefore, monitoring the temperature and stress conditions of optical cables while also monitoring fiber breakpoints is of profound significance for fault warning and maintenance. By measuring the frequency shift and intensity of Brillouin scattering light along the length of the fiber, temperature and strain information can be obtained, and the sensing distance can be quite long, thus having far-reaching engineering research value. The distributed fiber optic sensing system based on Brillouin Optical Time Domain Reflectometry (BOTDR) employs coherent detection technology, and the system principle is shown in Figure 1.

Figure 1 Principle of BOTDR Sensing System

The BOTDR fiber optic sensing system measures the self-generated Brillouin scattering signal of the fiber, which is very weak, but coherent detection technology can be used to improve the system’s signal-to-noise ratio. This scheme can work with a single light source and single end, making the system simple and easy to implement, while also monitoring fiber breakpoints, losses, temperature, and strain simultaneously. Transmission fiber optic sensors in medical applications. In medicine, the application of medical fiber optic sensors is currently mainly of the light transmission type. They are highly regarded for their compactness, insulation, immunity to radio frequency and microwave interference, high measurement accuracy, and good biocompatibility. This article will mainly introduce the applications of transmission fiber optics in pressure measurement, blood flow velocity measurement, and pH measurement. Additionally, they can also be applied to temperature measurement and medical image transmission.

1. Pressure Measurement. Currently, pressure sensors used clinically are mainly for measuring blood pressure within blood vessels, intracranial pressure, cardiac pressure, bladder, and urethral pressure. The pressure sensor used for measuring blood pressure is shown in Figure 1. The pressure-sensitive part is a waterproof membrane on the side wall of the probe catheter, connected to a cantilever micro-mirror. The mirror faces a fiber optic that transmits incident light to the mirror while also transmitting reflected light back. When pressure is applied to the membrane, it deforms and moves the cantilever, changing the angle of the mirror. The light beam from the fiber optic strikes the mirror and is reflected back to the end of the fiber optic. Since the direction of the reflected light changes with the angle of the mirror, the intensity of the reflected light received by the fiber optic also changes. This change is transmitted through the fiber to a photodetector at the other end, converting it into an electrical signal, thus allowing the pressure at the probe to be determined through voltage changes.

Figure 1 Fiber Optic Pressure Sensor Probe

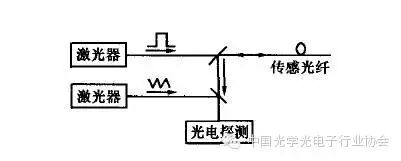

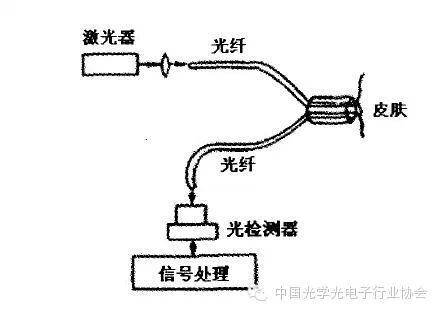

2. Blood Flow Velocity Measurement. The Doppler fiber optic velocity sensor measures the blood flow velocity in subcutaneous tissues, as shown in Figure 2. This device utilizes the end-face reflection phenomenon of fiber optics, and the measurement system structure is simple.

Figure 2 Fiber Optic Pressure Sensor Probe

The laser with a frequency of f is transmitted through a lens, and the fiber optic is sent to the skin tissue. For stationary tissues, such as blood vessel walls, the reflected light does not produce a frequency shift; however, for red blood cells flowing in capillaries, the reflected light will experience a frequency shift, with the frequency change being Δf. The intensity of the reflected light that experiences a frequency shift is proportional to the concentration of red blood cells, and the frequency change value is proportional to the velocity of red blood cell movement. The emitted light is collected through the fiber optic, mixed on a photodetector, and then processed by a signal processing device to obtain the velocity and concentration of red blood cells.

3. pH Measurement

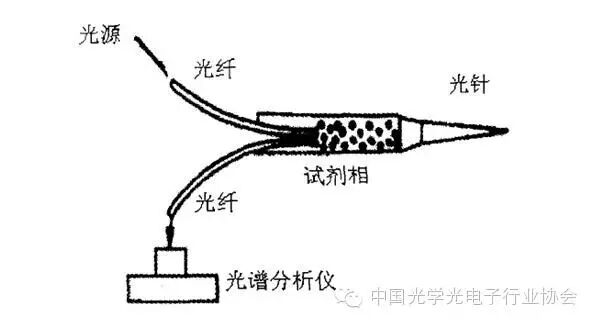

To determine the pH value of living tissues and blood, a fiber optic spectral sensor is used, as shown in Figure 3. Its working principle is based on measuring the intensity distribution spectrum of emitted and transmitted light as a function of wavelength. This sensor inserts two fibers into a cellulose membrane box that can permeate ions. The box contains reagents, and when the needle is inserted into tissue or blood vessels, body fluids seep into the reagents, causing the reagents to absorb light of a certain wavelength. By using a spectrometer to measure this change, the pH value of the blood or tissue can be determined.

Figure 3 Fiber Optic Spectrometer for pH Measurement