Source: WeChat Official Account “Sensor Technology” (ID: WW_CGQJS)

Author: Sensor Technology

Image Sensor Definition and Types

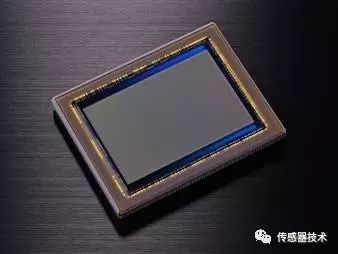

Image sensors are core components of various industrial and surveillance cameras, portable recorders, digital cameras, scanners, etc. Currently, this rapidly growing market has expanded into toys, mobile phones, PDAs, automobiles, and biomedicine.

Image Sensor Applications

Image Sensor Applications

The imaging lens projects external lighting (or self-luminous) scenes onto the image plane of the lens, forming a two-dimensional spatial light intensity distribution (optical image). A sensor that can convert this two-dimensional light intensity distribution into a one-dimensional time-sequential electrical signal is called an image sensor. Image sensors are important components of digital cameras.

According to the different components, image sensors can generally be divided into two main types: CCD (Charge-Coupled Device) and CMOS (Complementary Metal-Oxide Semiconductor).

In addition to these two commonly used types, there is another type called CIS (Contact Image Sensor), which is generally used in scanners. Because it is a contact scanning method (it must be kept very close to the original document), it can only use LED light sources, and its depth of field, resolution, and color performance currently do not match that of CCD sensors and cannot be used for scanning transparencies.

Contact CIS

Contact CIS

With the rapid development of solid-state imaging applications in the 1970s and 1980s, CCD technology and manufacturing processes have been optimized in terms of optical characteristics and imaging quality. For the past 25 years, CCD technology has dominated the trend of image sensors, being a high-resolution and high-quality image sensor that can be integrated onto a very small chip.

CMOS image sensors have rapidly developed in recent years and are gaining ground. CMOS offers performance comparable to CCD in mid-range and low-end applications, and it has a clear price advantage. With technological advancements, CMOS will also occupy a place in high-end applications.

Working Principle of Image Sensors

Working Principle of Image Sensors

An image sensor is a semiconductor device that can convert optical images into digital signals. The tiny photosensitive materials embedded in the sensor are called pixels. The more pixels contained in a sensor, the higher the resolution it provides. It functions like film but converts image pixels into digital signals.

History and Characteristics of CCD and CMOS Development

CCD was invented in 1969 by Willard S. Boyle and George E. Smith at Bell Labs.

Bell Labs

At that time, Bell Labs was developing imaging telephones and semiconductor bubble memory. By combining these two new technologies, Boyle and Smith developed a device they named “Charge ‘Bubble’ Devices”.

The characteristic of this device is that it can transfer charges along the surface of a semiconductor, and it was attempted to be used as a memory device, which could only input memory by “injecting” charges from a temporary storage unit. However, it was soon discovered that the photoelectric effect could generate charges on the surface of this device, thus forming digital images.

By the 1970s, Bell Labs researchers were able to capture images using simple linear devices, and CCD was born. CCD is still widely used in digital cameras and astronomy.

We all know that CCD is a medium that replaces traditional film in the digital age, and its working principle has also evolved from the original chemical sensitivity of film to light.

It is made of a highly photosensitive semiconductor material that converts light into charges, which are then converted into digital signals by an analog-to-digital converter chip. The digital signals are stored in the camera’s internal flash memory or built-in hard disk card after compression, allowing for easy data transfer to a computer, where image modifications can be made as needed.

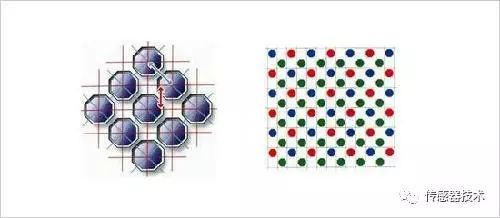

CCD consists of many photosensitive units, usually measured in millions of pixels. When the surface of the CCD is exposed to light, each photosensitive unit reflects charges on the component, and the signals generated by all the photosensitive units combine to form a complete image.

Notable Features of CCD:

1. Mature technology

2. High imaging quality

3. High sensitivity, low noise, large dynamic range;

4. Fast response speed, self-scanning function, low image distortion, no residual images;

5. Produced using ultra-large-scale integrated circuit technology, high pixel integration, precise dimensions.

There are many indicators to evaluate the quality of a CCD sensor, such as pixel count, CCD size, signal-to-noise ratio, etc. Among these, pixel count and CCD size are the most important indicators. Pixel count refers to the number of photosensitive elements on the CCD.

We can understand the images we capture as being composed of many small points, each point being a pixel. Obviously, the more pixels there are, the clearer the image will be. If the CCD does not have enough pixels, the clarity of the captured image will be greatly affected.

Therefore, the number of pixels in a CCD should be as high as possible. However, increasing the pixel count for better image quality will inevitably lead to increased manufacturing costs and decreased yield.

To address cost and other issues, a lower-cost, lower-power consumption, and highly integrated CMOS sensor emerged.

CMOS is an important chip in computer systems that holds the most basic data for system boot.

CMOS

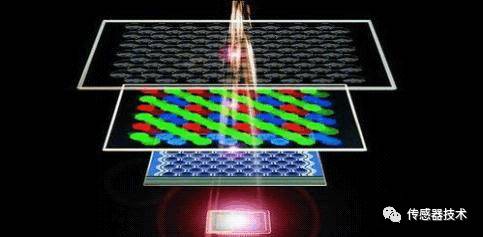

CMOS manufacturing technology is similar to that of general computer chips, primarily using silicon and germanium to create semiconductors. This allows for the coexistence of negatively charged N-type and positively charged P-type semiconductors, and the current generated by their complementary effects can be recorded and converted into images by processing chips. It was later discovered that CMOS could also serve as image sensors in digital photography.

CMOS

CMOS

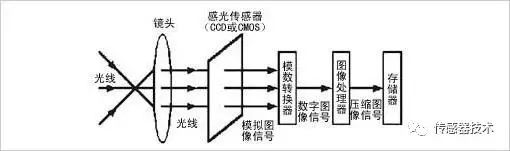

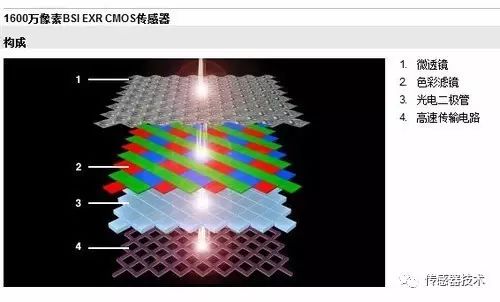

CMOS image sensors are a typical type of solid-state imaging sensor, sharing a common historical origin with CCD. CMOS image sensors generally consist of pixel unit arrays, row drivers, column drivers, timing control logic, AD converters, data bus output interfaces, control interfaces, etc., which are usually integrated onto the same silicon chip. The working process can generally be divided into reset, photoelectric conversion, integration, and readout.

The photoelectric information conversion function of CMOS is fundamentally similar to that of CCD, with the difference being in the method of information transfer after photoelectric conversion.

CMOS Structure

CMOS Structure

CMOS features a simple information reading method, fast output rate, low power consumption (about 1/10 of CCD chips), small size, lightweight, high integration, and low cost.

Considering that the manufacturing cost and yield of CMOS sensors are higher than those of CCD sensors, several well-known manufacturers began to increase their R&D efforts for CMOS sensors since 2000. Currently, the growth rate of CMOS has reached several times that of CCD.

We can see that even in the early digital SLR products from Nikon, some models still used CCD sensors, but in recent years, it has become increasingly rare to see CCD in the digital cameras released by Nikon, Sony, or Canon.

Although using CMOS sensors can reduce camera costs, image quality remains the most important factor for cameras. The biggest drawback of CMOS compared to CCD is image quality, primarily due to the fact that early CMOS had a significant flaw: as current changes, the frequency increases, inevitably generating heat, which ultimately leads to noise in the image and affects image quality.

When comparing CCD and CMOS sensors, the biggest advantage of CCD sensors is their high image quality, while the biggest advantage of CMOS is its low cost and suitability for mass production. As the drawbacks of CMOS are continuously improved,

Currently, some medium-format digital cameras or digital backs still use CCD sensors because different products have different requirements for image quality, which often results in medium-format digital products being significantly more expensive than ordinary digital cameras.

Thus, it can be said that the future direction of the camera market will still be centered around CMOS, continuously improving CMOS resolution and sensitivity, etc.

Industrial Cameras

Industrial Cameras

As times progress, cost-saving is a business principle that every merchant adheres to. The future of CCD may not necessarily lie in the camera market; in other fields, CCD will also be widely used due to its advantages.

Technology continues to develop, and I believe that in the future, there will certainly be more types of sensors emerging. This is just a matter of time. When we look back at the past, reflecting on the film era, the CCD era, and the CMOS era, we will surely marvel at the rapid development of technology.

Comparison of CCD and CMOS

1. Imaging Process

CCD and CMOS use the same photosensitive materials, thus the basic principle of electron generation after exposure to light is the same, but the reading processes differ: CCD transfers signals in frames or lines in coordination with synchronization and clock signals, resulting in a very complex circuit and slow readout rate; CMOS reads signals in a manner similar to DRAM, with a simple circuit and high readout rate.

2. Integration Level

Using special technology, CCD readout circuits are complex and difficult to integrate A/D conversion, signal processing, automatic gain control, precise amplification, and storage functions onto a single chip, generally requiring 3 to 8 chips to achieve this, along with a multi-channel non-standard power supply voltage.

In contrast, CMOS image sensors can easily integrate the aforementioned functions onto a single chip using large-scale integration manufacturing processes. Most CMOS image sensors have both analog and digital output signals.

3. Power Supply, Power Consumption, and Size

CCD requires multiple power supplies, has higher power consumption, and is larger in size. CMOS only requires a single power supply (3V~5V), with power consumption about 1/10 that of CCD, and highly integrated CMOS chips can be made very small.

4. Performance Indicators

CCD technology is already quite mature, while CMOS is in a period of vigorous development. Although currently high-end CMOS image quality does not match that of CCD, some indicators (such as transmission rate) have already surpassed that of CCD. Due to the many advantages of CMOS, many institutions at home and abroad have developed numerous products using CMOS image sensors.

The Six Major Hardware Technical Indicators of CCD and CMOS Image Sensors

Sometimes people may wonder why there are differences in image quality among high-definition network cameras, even when using the same components, and why the performance at night varies. This is actually related to the hardware technical indicators of the sensors (i.e., image sensors), whether CCD or CMOS, mainly involving “pixel, target size, sensitivity, electronic shutter, frame rate, and signal-to-noise ratio,” the six major hardware technical indicators.

Pixel:

The sensor has many photosensitive units that can convert light into charges, forming an electronic image corresponding to the scene. Each photosensitive unit corresponds to a pixel. The more pixels, the more details the sensor can detect, resulting in clearer images. Higher pixel counts mean better imaging quality.

Pixel

Related to our products at Zhongwei Century: A 100W network camera has a resolution of 1280X720, resulting in a pixel count close to 1 million pixels. A 130W resolution is 1280X960, resulting in a pixel count close to 1.3 million. From the image quality perspective, the 130W performs better than the 100W.

Target Size:

The size of the photosensitive part of the image sensor, typically expressed in inches. Similar to televisions, this data generally refers to the diagonal length of the image sensor. Common sizes include 1/3 inch, where a larger target size means better light transmission, while a smaller target size can more easily achieve a greater depth of field.

For example, a 1/2 inch sensor can achieve a relatively large light transmission, while a 1/4 inch sensor can more easily obtain a larger depth of field. Related to our products at Zhongwei Century: The 100W product is 1/4 inch, the 130W is 1/3 inch, and the 200W is 1/2.7 inch, which can be perceived from the image quality variations due to differences in target sizes.

Sensitivity:

This refers to the ability of CCD or CMOS and related electronic circuits to sense the strength of incident light. The higher the sensitivity, the stronger the photosensitive surface’s response to light, and the faster the shutter speed, which is particularly important when shooting moving vehicles or monitoring at night.

This explains why different cameras have significant differences in night vision capabilities; sensitivity is measured in V/LUX-SEC, where V (voltage) is the unit of voltage we usually refer to, and LUX-SEC is the unit of light intensity. A higher ratio indicates better night vision performance.

Electronic Shutter:

This is a term proposed in reference to the mechanical shutter function of cameras. It controls the exposure time of the image sensor. Since the exposure value of the image sensor is the accumulation of signal charges, the longer the exposure, the more signal charges accumulate, resulting in a larger output signal current. Faster electronic shutters correspond to lower sensitivity, suitable for shooting in bright light.

Frame Rate:

This refers to the number of images recorded or played back per unit of time. Continuously playing a series of images creates an animation effect. According to human visual perception, when the playback speed exceeds 15 frames per second (fps), the human eye can hardly perceive the jump; at speeds between 24 fps and 30 fps, flickering is virtually undetectable.

The frames per second (fps) or frame rate indicates how many times the graphics sensor can update per second. A higher frame rate results in a smoother and more realistic visual experience.

Signal-to-Noise Ratio:

This is the ratio of signal voltage to noise voltage, measured in dB. The signal-to-noise ratio typically provided by cameras is the value when AGC (Automatic Gain Control) is off, as AGC boosts small signals, which also raises the noise level.

A typical signal-to-noise ratio value is 45-55dB; if it is 50dB, there will be slight noise, but the image quality is good. If it is 60dB, the image quality is excellent with no noise. A higher signal-to-noise ratio indicates better noise control, which relates to the number of noise spots in the image. A higher signal-to-noise ratio gives a cleaner image, resulting in fewer spots in night vision images.

Conclusion:

Currently, CCD still outperforms CMOS in terms of performance. However, as CMOS image sensor technology continues to advance, with significant improvements in noise and sensitivity, the gap between them is narrowing. Some industry insiders even believe that the future sensor market will belong to CMOS. So, which type of sensor is more suitable for the industrial camera market? Or which type of sensor will better meet future demands?

The answers to these questions are evident: there are many factors to weigh when choosing a certain chip.

CCD and CMOS image sensors each have their advantages and disadvantages. In the entire image sensor market, they have a relationship of both competition and complementarity. Sometimes, the two types of sensors can be complementary and suitable for different applications. Regardless of which sensor is more powerful, their technological advancements will undoubtedly greatly promote the development of the image sensor market and the machine vision industry.

This article is an original piece from the Sensor Technology platform. Reproduction requires authorization from us!

Editor: Han Lu