The use of a multimeter can be divided into the following types:

First, turn the knob to the AC voltage measurement position, perform mechanical zeroing, and when the value is zero, use the two probes to contact the live wire and the neutral wire of the circuit to be tested.

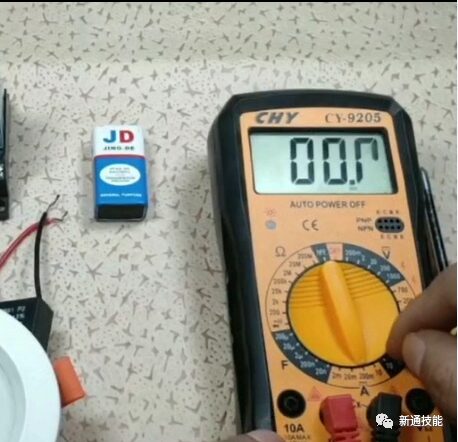

Second, turn the knob to the resistance measurement position, perform mechanical zeroing, and when the value is zero, connect the tips of the two probes together for ohm zeroing, then you can measure the resistance to be tested.

Third, turn the knob to the AC current measurement position, perform mechanical zeroing, and when the value is zero, you can measure the circuit current.

Steps: How to Use a Multimeter (including: how to determine the pins of a transistor using a multimeter) (1) Before using the multimeter, perform “mechanical zeroing”, which means setting the multimeter pointer to the zero voltage or zero current position when there is no measured electrical quantity.

(2) During the use of the multimeter, do not touch the metal parts of the probes with your hands, as this not only ensures measurement accuracy but also guarantees personal safety.

(3) When measuring a certain electrical quantity, do not change the range while measuring, especially when measuring high voltage or large current, as this should be done with caution. Otherwise, it may damage the multimeter. If you need to change the range, disconnect the probes first, then change the range before measuring.

(4) The multimeter must be placed horizontally during use to avoid errors. Also, pay attention to avoid external magnetic fields affecting the multimeter.

(5) After using the multimeter, set the switch to the maximum range of AC voltage. If it will not be used for a long time, the internal battery of the multimeter should be removed to prevent battery corrosion of other components inside the multimeter.

An electrician is a person engaged in the installation, debugging, maintenance, and repair of machinery and electrical systems and components. Electricians must comply with national safety production regulations and hold certificates to ensure that maintenance personnel have a certain level of professionalism for installation, debugging, maintenance, and repair work.

The main content is divided into two types: vocational qualification certificates (level certificates) and work permits (IC cards). The school has applied for work permits (IC cards).

Electrician categories include low-voltage electricians, maintenance electricians, etc.

Maintenance electrician course training includes: 1. Subject 1 (Electrical Safety Tools): Use of multimeters, grounding resistance testers; clamp meters, megohmmeters; electrical insulation tools;

2. Subject 2 (Safety Operation Techniques): Installation and wiring of three-phase asynchronous motor control circuits; T-joint and flat joint of single-strand wires; T-joint and flat joint of multi-strand wires and insulation treatment; installation and wiring of three-phase asynchronous motor forward and reverse control circuits;

Installation of single-phase energy meter with single switch-controlled lighting circuit; installation of single-phase energy meter with threaded lamp holders and sockets; installation of single-phase energy meter with threaded lamp holders and sockets; wiring of motor control circuits with fuses (circuit breakers), instruments, and current transformers;

Installation of single-phase energy meter with double switch-controlled lighting circuit;

3. Subject 3 (Hazard Elimination at Work Sites): Safety risks and occupational hazards assessment at work sites; safe operation during live work; identification of electrical safety signs;

4. Subject 4 (Emergency Response at Work Sites): One-person manual cardiopulmonary resuscitation; prevention of electric shock accidents and methods; selection and use of fire extinguishers; external cardiac compression technique.