With the implementation of the “Industry 4.0” strategy, the development of computer technology, communication technology, and IT technology has infiltrated the industrial control field. The most significant manifestation of this is the technology of industrial fieldbus and industrial Ethernet. The widespread use of industrial fieldbus technology, especially Ethernet technology, has brought profound changes to automation technology.

[Fieldbus]

Fieldbus is a digital, bidirectional transmission, multi-branch structured communication network used in production sites, connecting intelligent field devices and automation measurement and control systems.

It is an industrial data bus and serves as the underlying data communication network in the automation field.

[Control Components]

1. Fieldbus Control System

The software is an important component of the system, including configuration software, maintenance software, simulation software, device software, and monitoring software. First, select the development configuration software and control human-machine interface software (MMI). Through the configuration software, connections between functional blocks are completed, functional block parameters are selected, and network configuration is carried out. During the network operation, the system collects data in real-time, processes it, and performs calculations. It optimizes control and logic control for alarms, monitoring, display, reports, etc.

2. Fieldbus Measurement System

Its characteristics include high-performance measurement of multiple variables, enabling measuring instruments to have computational capabilities and more functions. Due to the use of digital signals, it has high resolution, accuracy, strong anti-interference, and anti-distortion capabilities, while also providing status information about the instruments, allowing adjustments to the processing process.

3. Device Management System

This system can provide diagnostic information about the devices themselves and the processes, management information, and operational status information (including smart instruments), as well as manufacturing information provided by vendors.

4. Bus System Computer Service Module

The client/server model is currently a popular network computer service model. The server represents the data source (provider), while the application client represents the data user, which retrieves data from the data source for further processing. The client runs on a PC or workstation, while the server runs on a minicomputer or mainframe, utilizing the intelligence, resources, and data of both parties to accomplish tasks.

5. Database

This can dynamically store a large amount of data and applications in an organized manner, enabling full data sharing and cross-access, with a high degree of independence. Industrial equipment parameters continuously change during operation, generating large amounts of data, with high real-time requirements for operation and control. Thus, a distributed relationship with mutual access and real-time data systems is formed.

6. Hardware and Software of Network Systems

Network system hardware: system management host, server, gateway, protocol converter, hub, user computers, and other lower-level intelligent instruments.

Network system software: NetWarc, LAN Manager, Vines.

Server operating software: Linux, OS/2, Windows NT, application software database, communication protocols, network management protocols, etc.

[Bus Classification]

Currently, there are about forty types of fieldbus in the world, most of which are used in process automation, pharmaceuticals, manufacturing, transportation, defense, aerospace, agriculture, and buildings. The current industrial bus networks can be classified into three categories: 485 network, HART network, and FieldBus network.

485 Network: RS485/MODBUS is a popular industrial networking method characterized by its simplicity and convenience. Many instruments now support RS485, and instrument manufacturers are increasingly turning to support RS485/MODBUS due to the low cost and variety of RS485 conversion interfaces available. At least in the low-end market, RS485/MODBUS will remain the primary industrial networking method.

HART Network: HART is a transitional bus standard proposed by Emerson, characterized by the superimposition of digital signals on the 4-20 mA current signal. However, this protocol is not truly open; one must join its foundation to obtain the protocol, which incurs certain fees. HART technology is mainly monopolized by a few large foreign companies, and in recent years, some domestic companies have also engaged in it, but have not yet reached the level of foreign companies. Many smart instruments now come with [HART round cards], supporting HART communication functions. However, in domestic situations, this functionality has not been truly utilized for device networking and monitoring, with most only using handheld devices for parameter settings. In the long run, due to low communication speeds and networking difficulties, the application of HART instruments will likely decline.

FieldBus Network: Fieldbus is one of the hot technologies in the automation field today, often referred to as the computer local area network of automation. Its emergence marks the beginning of a new era in automation control technology. Fieldbus is a digital, serial, multi-station communication network connecting instruments in the control field with control devices in the control room. Its key feature is the ability to support bidirectional, multi-node, all-digital communication. In recent years, fieldbus technology has become a hot topic in international automation and instrumentation development, revolutionizing traditional control system structures and advancing self-control systems towards “intelligent, digital, informational, networked, and decentralized” directions, forming a new type of network communication distributed control system—Fieldbus Control System (FCS). However, up to now, fieldbus has not formed a truly unified standard; multiple standards such as ProfiBus, CANbus, and CC-Link coexist, each with its own space for existence. The timeline for unification remains uncertain. Currently, the variety of instruments supporting fieldbus is still relatively limited, leaving little room for choice, and the prices are relatively high, resulting in low usage.

[Characteristics, Advantages, and Disadvantages]

1. Characteristics

Field control devices have communication functions, facilitating the formation of a factory-level control network.

The openness and consistency of communication standards enable interoperability between devices.

The standardization of functional blocks and structures allows interchangeability between devices with similar functions.

Decentralization of control functions at the field level enhances the decentralized structure of the control system.

2. Advantages

Fieldbus enables self-control devices and systems to enter the information network industry, opening up broader application fields;

Multiple control devices can be connected to a twisted pair, saving installation costs;

Reduces maintenance expenses;

Increases system reliability;

Provides users with greater flexibility in system integration.

3. Disadvantages

Transmission delays in data packets, instantaneous errors in the communication system, packet loss, and inconsistencies in sending and receiving order can undermine the determinism originally inherent in traditional control systems, complicating the analysis and synthesis of control systems and negatively impacting their performance.

[Industrial Ethernet]

Industrial Ethernet refers to a communication network that is technically compatible with commercial Ethernet but meets the needs of industrial sites in terms of real-time performance, reliability, and environmental adaptability in product design. It has developed after fieldbus technology and is recognized as the most promising industrial communication network.

The essence of industrial Ethernet is the transition of Ethernet technology from office automation to industrial automation.

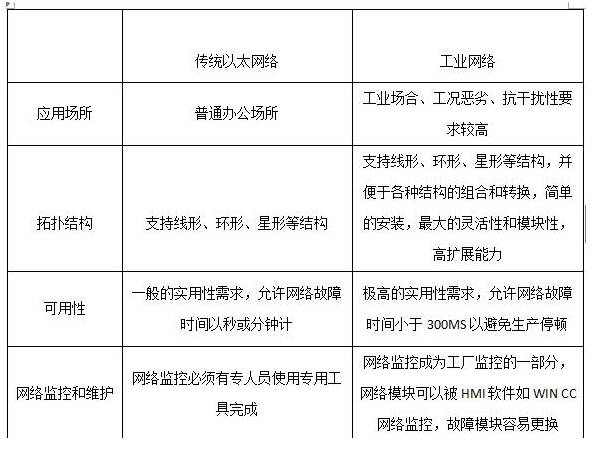

[Comparison of Industrial Ethernet and Traditional Ethernet]

[Operational Requirements]

1. The high temperature, humidity, air pollution, and corrosive gases in industrial production environments require industrial-grade products to have climate adaptability and to be resistant to corrosion, dust, and water.

2. The presence of dust, flammable, explosive, and toxic gases in industrial production sites necessitates explosion-proof measures to ensure safe production.

3. The high levels of vibration and electromagnetic interference in industrial production sites require industrial control networks to have mechanical environmental adaptability (such as vibration and shock resistance), electromagnetic environmental adaptability, or electromagnetic compatibility (EMC).

4. The power supply for industrial network devices typically uses low-voltage DC power standards within cabinets, with most industrial environments requiring 24V DC power.

5. Standard rail installation is used, making installation convenient and suitable for industrial environmental requirements. Industrial network devices should be easily installed within industrial control cabinets and easily replaced.

[Main Standards]

Industrial Ethernet is developed according to the requirements of industrial control, with appropriate application layer and user layer protocols, allowing Ethernet and TCP/IP technology to be effectively applied to the control layer and extended to the field layer. In the information layer, it adopts all effective and latest achievements from the IT industry as much as possible, thus making the application of industrial Ethernet in industry a completely different concept from traditional Ethernet.

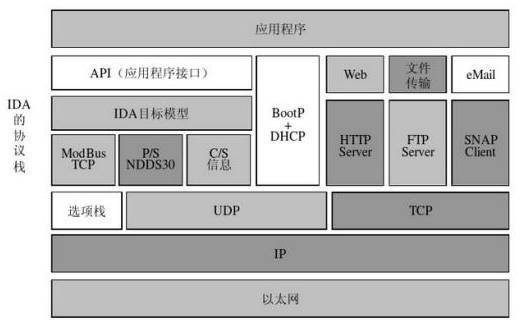

1. IDA Communication Structure and Protocol

IDA is an industrial Ethernet specification completely based on Ethernet, combining a real-time web-based distributed automation environment with a centralized security architecture, aiming to create a TCP/IP-based decentralized automation solution.

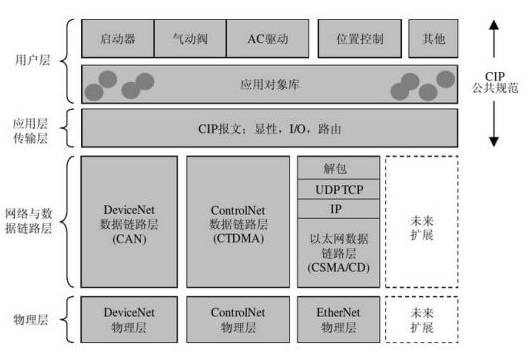

2. Ethernet/IP Communication Structure and Protocol

ODVA controls not only DeviceNET and ControlNet but also another bus, EtherNet/IP, which binds the target libraries of DeviceNet and ControlNet at the application and user layers (CIP, which includes all classic PLC operations) with Ethernet physical media.

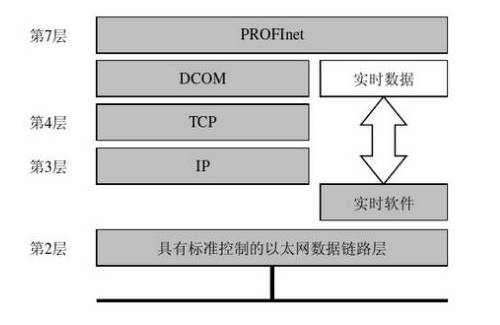

3. PROFInet Communication Structure and Protocol

As shown in the figure, its data link layer employs a transmission protocol designed to reduce the time required for processing the communication stack, significantly shortening network refresh times and ensuring refresh times within 5-10 ms. Besides cyclic transmission, real-time channels can also accomplish non-cyclic (event-triggered, process data modification, operational command issuance, etc.) transmissions. Additionally, network management, web functionalities, and direct integration of I/O devices should be included.

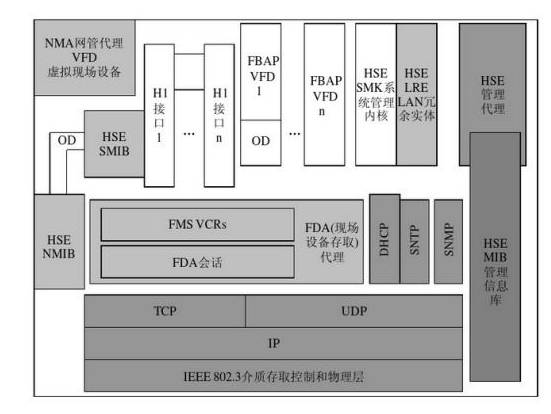

4. HSE Communication Structure and Protocol

The FF (Fieldbus Foundation) in the United States has developed the FCS system for communication networks above the control level using high-speed Ethernet, while the H1 fieldbus is still used below the control level, forming an open system architecture for information integration. HSE adheres to standard Ethernet specifications. FF specifies 21 functional blocks for basic process control and advanced process control. These standard functional blocks reside in field devices connected to HSE, and can be linked through configuration. To facilitate complex batch and hybrid control applications, FF also specifies flexible functional blocks that support monitoring of data collection, subsystem interfaces, event sequencing, multi-channel data collection, and can serve as interconnectors for communication with PLCs and other protocols. Thus, we can conclude that HSE industrial Ethernet provides various solutions for continuous real-time control required in continuous process control industries and batch manufacturing, offering a relatively mature standard protocol for integrating continuous process control systems, batch control systems, and enterprise information management systems such as MES and ERP.

[Issues to Address in Industrial Control Applications]

Industrial Ethernet is generally compatible with commercial Ethernet technically, but in product design, it meets the needs of industrial sites in terms of real-time performance, reliability, and environmental adaptability, making it a typical industrial communication network. Compared to commercial Ethernet, Industrial Ethernet has special requirements in the following aspects:

1. Requires high real-time performance and good time determinism

2. Information transmitted is mostly short frame information, with frequent information exchanges

3. Strong fault tolerance, good reliability, and safety

4. Highly decentralized control network structure

5. Control network protocols should be simple and practical, with high efficiency

6. Intelligent control devices and autonomous control functions

7. High-efficiency communication with information networks, facilitating integration with information networks

8. Reliability and environmental adaptability of devices

9. Long-distance transmission

10. Bus-powered

11. Network security

12. Interoperability

[Advantages]

1. Wide Application

Ethernet is currently the most widely used computer network technology, receiving extensive technical support. The most typical form of Ethernet application is: Ethernet + TCP/IP + web. Almost all programming languages support the development of Ethernet applications.

2. Low Cost

Due to the widespread application of Ethernet, it has garnered significant attention and support from hardware developers and manufacturers, resulting in a variety of hardware products for users to choose from. Additionally, due to its widespread use, hardware prices are relatively low.

3. High Communication Speed

Currently, Ethernet communication speeds of 10M, 100M fast Ethernet are widely applied, and 1000M Ethernet technology is gradually maturing, with 10G Ethernet currently under research, which is significantly faster than existing fieldbus technologies.

4. Abundant Software and Hardware Resources

Ethernet has been in use for many years, and there is a wealth of experience in its design and application. A large amount of software resources and design experience can significantly reduce system development and training costs, thus lowering the overall cost of the system and greatly accelerating system development and deployment.

5. Strong Sustainable Development Capability

Due to the widespread application of Ethernet, its development has received significant attention and substantial technical investment, forming global technical support. In this rapidly changing information era, the survival and development of enterprises will largely depend on a fast and effective communication network management. The development of information technology and communication technology will become even faster and more mature, ensuring the continuous advancement of Ethernet technology.

6. Ease of Achieving Integrated Management and Control

It is easy to achieve seamless integration of control networks with information networks, establishing a unified enterprise network, allowing for easy access of embedded controllers, intelligent field measurement and control instruments, and sensors to Ethernet, even connecting to the Internet.

We welcome all machine enthusiasts to leave your wonderful comments below!

Link: How to Become an Industrial Robot Application Engineer?

Link: How to Become an Industrial Robot Application Engineer?

Link: How to Become an Industrial Robot Application Engineer?

We are not just carriers of dry goods.

DistanceOnly a Follow Away from Industrial Robot Masters

Guide Car Robot Academy, cradle of robotic craftsmen.