Ceramic pressure sensors are pressure sensors made from special ceramic materials through a unique manufacturing process. Ceramic is a well-known material with high elasticity, corrosion resistance, wear resistance, impact resistance, and vibration resistance. The thermal stability of ceramics and thick film resistors allows them to operate in a temperature range of -40℃ to 125℃, with high measurement accuracy and stability. The electrical insulation level is greater than 2KV, the output signal is strong, and long-term stability is good.

High-performance, low-cost ceramic sensors will be the development direction of pressure sensors. In Europe and the United States, ceramic sensors are trending to fully replace other types of sensors, and more and more users in China are opting for ceramic sensors over diffusion silicon pressure sensors.

The substrate of ceramic pressure sensors is Al2O3 ceramic, which can be classified into capacitive pressure sensors and piezoresistive pressure sensors based on the principle of operation.

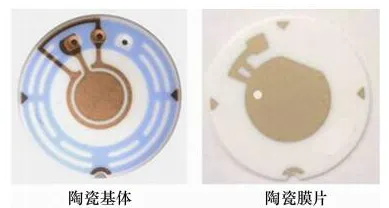

① Ceramic Capacitive Pressure Sensors

Ceramic capacitive pressure sensors use a fixed ceramic base and a movable ceramic diaphragm structure. The movable diaphragm is sealed and fixed to the base using glass paste or similar methods. The inner sides of both components are printed with electrode patterns, forming a variable capacitor. When the pressure of the medium applied to the diaphragm changes, the capacitance between them also changes. After conditioning by a chip, this signal is output for further use. The capacitive technology of ceramics has advantages such as moderate cost, wide measurement range, good temperature characteristics, consistency, and long-term stability.

▲Structure Diagram of Ceramic Capacitive Sensitive Element

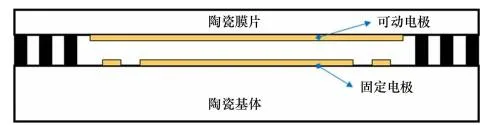

Since the edge of the ceramic diaphragm is fixed on the ceramic base, the surrounding support causes significant deformation in the center and minimal deformation at the edges when subjected to force, leading to non-linearity in capacitance and reduced sensitivity. To minimize temperature effects and edge effects, a circular single electrode is designed on the ceramic diaphragm as a common electrode, while dual electrodes with equal area are set on the ceramic cover plate, forming a coaxial annular dual-capacitance sensor.

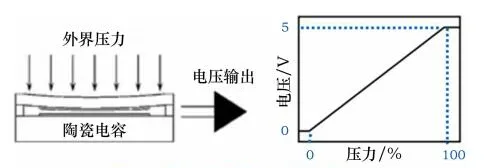

▲Principle of Ceramic Capacitive Pressure Sensor

The center measures capacitance Cp, while the outer annulus is the reference capacitance Cr, with the outer side of Cr being fixed. The subsequent signal conditioning circuit processes the pressure difference between the two capacitances, using a square wave excitation signal to convert the changes in Cp and Cr into DC voltage outputs. The measurement of the external pressure magnitude is determined by the difference in these two output voltages.

The dual-capacitance structure significantly reduces the non-linear error of the sensor system. Additionally, when the ambient temperature changes, both capacitances experience the same temperature change, resulting in consistent temperature effects that cancel out measurement errors due to temperature variations, achieving temperature self-compensation.

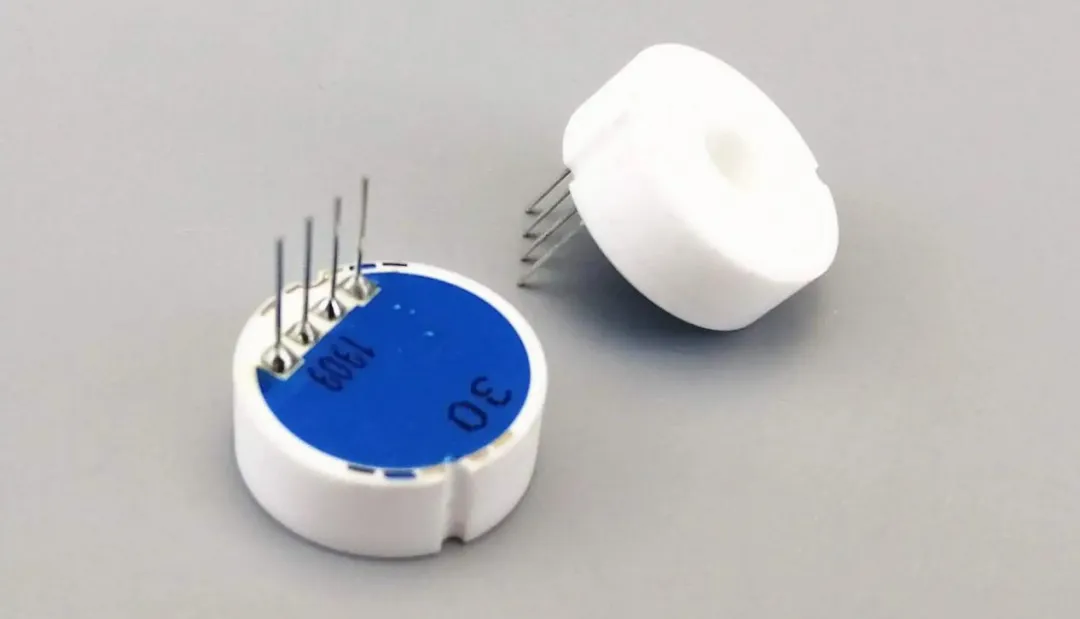

▲Ceramic Capacitive Pressure Sensor (Image Source: Shanghai Desabao)

Ceramic capacitive pressure sensors can be widely used for pressure detection of various media such as water, gas, and liquids due to their advantages of corrosion resistance, impact resistance, no hysteresis, and strong medium compatibility. They are particularly suitable for working in harsh environments in automotive systems. For emerging application markets of pressure sensors in the Internet of Things and home appliances, the impact resistance of ceramic capacitive sensors can be applied to water pressure measurement in water supply networks, perfectly addressing the water hammer effect; for variable pressure applications such as pressure cookers, the ceramic capacitive flat diaphragm structure can prevent clogging.

② Ceramic Piezoresistive Pressure Sensors

Ceramic piezoresistive pressure sensors mainly consist of a ceramic ring, ceramic diaphragm, and ceramic cover plate. The ceramic diaphragm acts as a force-sensitive elastic body, and a Wheatstone bridge circuit is formed on it using thick film technology. Due to the piezoresistive (deformation) effect of the resistors, a voltage signal is generated.

▲Ceramic Piezoresistive Pressure Sensor (Image Source: Internet)

Thick film resistors are printed on the back of the ceramic diaphragm, connected to form a Wheatstone bridge (closed bridge). When the pressure is zero, the bridge is in a balanced state, and the output voltage is zero. When pressure is applied to the bridge, the diaphragm deforms, causing changes in the resistance values of the four resistors, resulting in an unbalanced state of the bridge and generating a voltage signal that is highly linear and proportional to the pressure applied and the excitation voltage. Due to the piezoresistive (deformation) effect of the resistors, a voltage signal is generated. The standard signal is calibrated to 2.0/3.0/3.3mV/V, etc., depending on the pressure range, and can be compatible with strain sensors. Through laser calibration, the sensor exhibits high temperature stability and long-term stability, with built-in temperature compensation from 0 to 70℃, allowing direct contact with most media.

For submissions, reprints, or collaborations, please contact WeChat:MatResFron001

Welcome to leave comments and share your views.Support the author by clicking the lower right corner “like”” and “viewing”↓↓↓