Printed Circuit Board

Comprehensive Design

The comprehensive design of a Printed Circuit Board (PCB) is a complex process that involves multiple fields such as electronic engineering, materials science, thermodynamics, and signal integrity.

1. Preliminary Design Preparation

1. Requirement Analysis

Functional Requirements: Division of circuit functional modules (power supply, control, communication, etc.)

Performance Indicators: Operating frequency, power density, EMC requirements

Mechanical Constraints: Dimensions, installation methods, connector positions

Environmental Requirements: Operating temperature range, dust and water resistance levels

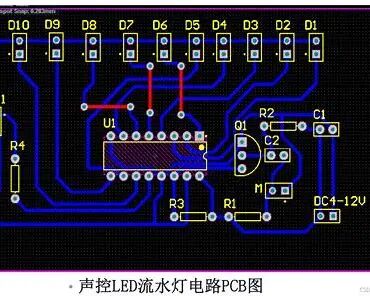

2. Schematic Design

Using EDA tools (such as Altium Designer, KiCad, Cadence, etc.)

Establish component libraries: Synchronize verification of symbol libraries and package libraries

Generate netlist: Ensure electrical connection correctness

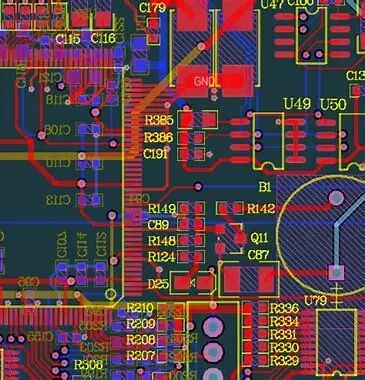

2. Core Design Phase

1.Layout Design

Functional zoning principles

Prioritize layout of key components: CPU, high-frequency devices, power devices

Thermal planning: Layout of heat-generating components and heat dissipation channels

Interface component positioning: Comply with mechanical structure requirements

2.Routing Design

Signal integrity control:

Impedance matching (microstrip line/stripline calculation)

Equal length routing (high-speed differential pairs, DDR, etc.)

3W principle (line spacing ≥ 3 times line width)

Power integrity:

Power plane segmentation

Decoupling capacitor layout (distributed by frequency band)

Electromagnetic compatibility design:

Sensitive signal shielding

Minimize ground loop

Filter circuit layout

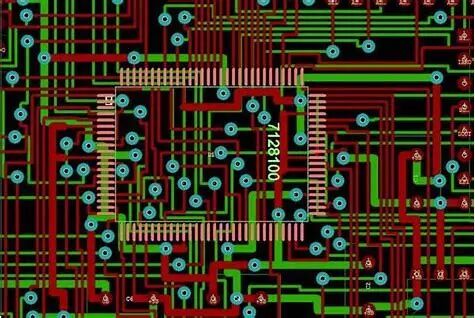

3.Stack-up Design

Typical 4-layer board structure:

Top Layer

GND Plane

Power Plane

Bottom Layer

High-speed board recommendations:

Signal layers adjacent to reference planes

Symmetrical stack-up structure to control warpage

3. Design Verification and Optimization

1.Design Rule Check (DRC)

Line width/line spacing verification

Hole aspect ratio check

Solder mask bridge check

2.Signal Integrity Simulation

Using tools such as HyperLynx/Sigrity

Key signal eye diagram analysis

Cross-talk simulation

3.Thermal Simulation Analysis

Identify thermal hotspot areas

Evaluate the effectiveness of heat dissipation solutions

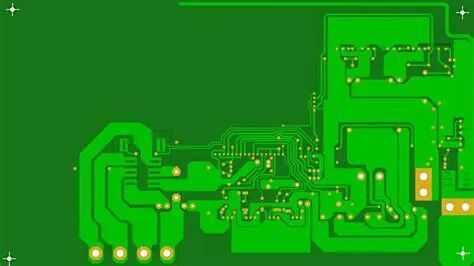

4. Manufacturing Output Preparation

1.Production File Generation

Gerber files (RS274X format)

Drilling files (Excellon format)

Assembly drawings (including component coordinate files)

2.Process Requirements Specification

Surface treatment options:

Conventional: HASL (Hot Air Solder Leveling)

High density: ENIG (Electroless Nickel Immersion Gold)

Special processes:

Blind and buried vias

Impedance control tolerance

5. Design for Manufacturability (DFM)

1.Component spacing control:

SMD component spacing ≥ 0.3mm

5mm no-layout zone around connectors

2.Pad Design:

Solder mask opening compensation

Test point design (diameter ≥ 0.8mm)

3.Edge Treatment:

V-cut or stamp hole design

Process edge width ≥ 5mm

6. Debugging and Verification

1.First Board Inspection:

AOI (Automated Optical Inspection)

ICT (In-Circuit Testing)

2.Functional Verification:

Power system testing (ripple/noise)

Signal quality testing (rise time/overshoot)

EMC pre-testing (radiated emissions/immunity)

7. Design Iteration Optimization

1.Issue tracing mechanism

2.Version control management

3.Accumulation of design experience

8. Advanced Design Techniques

1.Key points for high-speed design

Back drilling technology (elimination of Stub)

Serpentine routing for length compensation

Via optimization (handling of Via stub)

2.RF Circuit Design

Co-planar waveguide structure

Antenna feed point impedance matching

Shielding cavity design

3.Rigid-flex board design

Bending radius control

Stress relief in transition zones

Common Design Standards

1. IPC Standards:

IPC2221 (General Standard)

IPC7351 (Package Design)

IPC6012 (Rigid Board Specification)

2.National Standards:

GB/T4588 series

Recommended Toolchain

Schematic Design:OrCAD, PADS Logic

PCB Design:Allegro, Altium Designer

Simulation Tools:ANSYS SIwave, Keysight ADS

Version Management:Git + Altium 365

Design Quality Assessment Metrics

1.First Pass Yield (FPY)

2.Mean Time Between Failures (MTBF)

3.Wiring density per unit area

4.EMC certification pass rate

A successful PCB design requires a balance of electrical performance, manufacturability, and cost-effectiveness. It is recommended to adopt a modular design approach, establish standardized design specifications, and validate key designs through simulation in advance. With the advancement of technology, it is advisable to focus on:

HDI (High-Density Interconnect) technology

Embedded component technology

3D printing PCB technology

AI-assisted routing technology

Remember to conduct at least 3 design reviews before formal mass production and reserve 10-15% of the budget for design iteration optimization.

END