In the wave of automotive electronics transforming into “software-defined vehicles”, embedded software testing is upgrading from the traditional “verification phase” to a core competitive advantage that determines vehicle functional safety and user experience. When the code volume of a smart car exceeds 100 million lines, how can we build a reliable testing system within a complex electronic and electrical architecture? This article analyzes the advancement path of automotive embedded testing talents from capability models, practical paths to industry certifications.

In the wave of automotive electronics transforming into “software-defined vehicles”, embedded software testing is upgrading from the traditional “verification phase” to a core competitive advantage that determines vehicle functional safety and user experience. When the code volume of a smart car exceeds 100 million lines, how can we build a reliable testing system within a complex electronic and electrical architecture? This article analyzes the advancement path of automotive embedded testing talents from capability models, practical paths to industry certifications. 1. Building a “Full-Stack Testing” Capability Matrix

1. Building a “Full-Stack Testing” Capability Matrix

(1) In-depth Attack on Underlying Technologies

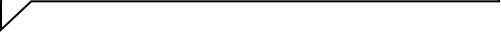

1. Hardware-in-the-Loop Testing (HIL)

Device-level testing development: Build HIL testing systems based on platforms like dSPACE and Vector CANoe to simulate the real operating environment of ECUs. For example, in BMS testing, simulate the voltage/temperature characteristics of the battery pack through HIL devices to verify that the SOC estimation algorithm has an error of <2% in the temperature range of -40℃ to 85℃.

Real-time testing optimization: In ESP body stability system testing, inject millisecond-level brake signals through HIL devices to verify the response delay of the control algorithm (requirement <10ms), and capture CAN bus waveforms with an oscilloscope to ensure no data frames are lost during transmission.

2. Comprehensive Software Testing Methodology

Model-Based Testing (MBT): Use MATLAB/Simulink to build testing models and automatically generate test cases that cover requirements. For example, in the Adaptive Cruise Control (ACC) project, simulate following scenarios (front vehicle acceleration/deceleration, lane changes) using Stateflow state machines to generate over 2000 test cases, achieving 100% requirement coverage.

Combining Static and Dynamic Testing:

Static Testing: Use Coverity to scan for code defects, focusing on buffer overflows (e.g., array out-of-bounds during CAN message parsing), wild pointers, and other issues in automotive embedded software;

Dynamic Testing: Execute MC/DC testing through VectorCAST to ensure that the code coverage of key control logic (e.g., torque distribution algorithm) in the power domain controller exceeds 95%.

3. Integration of Functional Safety and Testing

ISO 26262 Testing Strategy: Design a layered testing scheme for ASIL-D level systems:

Component Level: Validate safety mechanisms through Fault Injection Testing (FIT), such as simulating sensor failures to check if the ECU can trigger a safe state within 50ms;

System Level: Build safety analysis models using PREEvision and analyze test data with DIADEM to ensure the random hardware failure probability (PFH) is <10^-9/h.

Application of Safety-Related Testing Tools: Proficiently use tools like Tessy and LDRA to complete safety testing. For example, in the steering controller project, generate ISO 26262 compliant test reports using Tessy to demonstrate the effectiveness of safety mechanisms.

(2) Horizontally Expand Cross-Domain Testing Skills

1. Domain Controller Integration Testing

Cross-Domain Communication Testing: In the intelligent driving domain controller, test the reliability of SOME/IP service calls, such as simulating network disconnection in the vehicle Ethernet to verify the communication switching delay between the control domain and cabin domain (requirement <50ms), ensuring no data loss during service reconstruction.

Functional Coordination Testing: Design cross-domain scenario test cases, such as in the “rainy night autonomous driving” scenario, synchronously verify the coordinated response of cameras (vision domain), radars (perception domain), and braking systems (control domain), ensuring the emergency braking distance error is <0.5m.

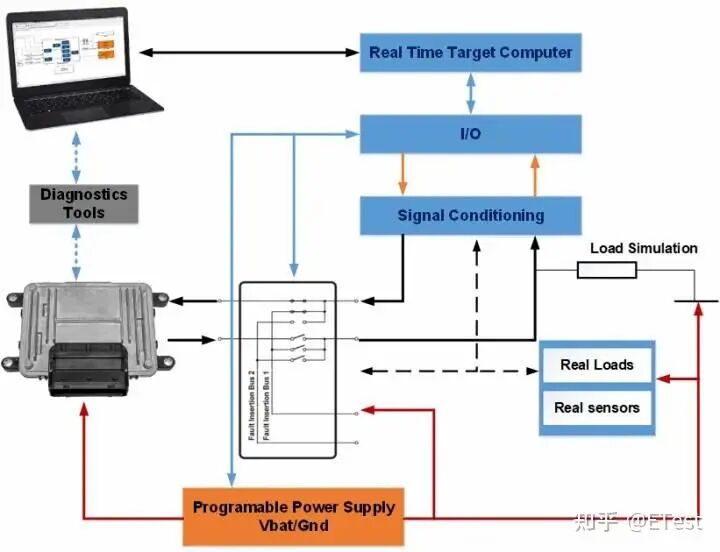

2. OTA Upgrade Testing and Information Security Testing

Full Process Testing for OTA:

Upgrade Package Integrity: Verify the correctness of the differential upgrade algorithm, ensuring that the byte difference rate between the unpacked upgrade package and the original firmware reaches 100%;

Upgrade Robustness: Simulate network interruptions and power fluctuations during the upgrade process to verify the ECU’s rollback mechanism (requirement to restore to pre-upgrade state within 30 seconds);

Information Security Testing: Based on ISO/SAE 21434 standards, test the anti-attack capabilities of the onboard system, such as using penetration testing tools to simulate hackers injecting malicious CAN messages to verify if the ECU can identify and block illegal commands within 10ms.

2. Building “Non-Replicable” Testing Barriers through Practical Projects

(1) Benchmark Projects for Vehicle-Level Testing

1. Integration Testing of New Energy Vehicle Power Systems

Project Challenge: Conduct full-scenario testing for the collaborative control of motor controllers, battery management systems (BMS), and vehicle controllers (VCU), covering environmental temperatures from -30℃ to 60℃.

Core Actions:

Design extreme condition test cases: Continuously fast charge 10 times at -25℃ to verify if the BMS thermal management strategy can maintain the battery temperature within 0℃ to 45℃;

Develop automated testing scripts: Use Python+CANoe to implement 24-hour uninterrupted loop testing of the power system, capturing sporadic faults (e.g., protection response time during motor stalling);

Quantified Results: Discovered and resolved 127 potential defects, including the battery overcharge protection delay issue (optimized from 200ms to 50ms), directly enhancing vehicle safety.

2. OTA Testing for Intelligent Cabin Domain Controllers

Technical Breakthrough: Construct an OTA testing matrix covering over 100 ECUs, simulating upgrade scenarios under different network environments (4G, 5G, Wi-Fi).

Key Achievements:Developed an upgrade conflict detection tool: Automatically identifies resource competition between ECUs being upgraded simultaneously (e.g., communication congestion when sharing the CAN bus), optimizing upgrade scheduling strategies, reducing overall vehicle upgrade time from 45 minutes to 20 minutes;

Designed edge scenario tests: Verify the upgrade breakpoint resume capability in weak signal environments such as tunnels and underground garages, ensuring that upgrades can continue from the breakpoint after signal recovery, achieving a success rate of 99.9%;

(2) Secondary Development and Automation of Testing Toolchains

1. Development of Testing Scripts Based on Python

Practical Case: Developed a CANoe test case automatic generation tool that parses functional descriptions in requirement documents (SRS) to automatically generate corresponding CAPL test scripts. For example, inputting “When the vehicle speed > 120km/h, the instrument should light up the overspeed warning light” allows the tool to automatically generate a complete test case including speed simulation, signal monitoring, and result verification, improving efficiency by 50%.

Output: Formed a standardized test script library covering 8 major areas such as body control and powertrain, with a reuse rate exceeding 70%.

2. Building a CI/CD Testing Pipeline

Process Optimization: Embed testing phases into the software development process to achieve an automated closed loop of “code submission → static analysis → unit testing → integration testing”. For example, configure in GitHub Actions:

Automatically trigger Coverity static scanning after each code submission to block the integration of code containing high-risk defects;

Run VectorCAST unit tests every night, generating coverage reports and sending them to the development team, requiring a 100% issue fix rate before proceeding to the next phase;

3. Anchoring Industry Certifications to Build a “Scarcity” Label

1. ISTQB Automotive Software Testing Certification (CTFL – AUT)

Certification Value: Launched by the International Software Testing Qualifications Board (ISTQB), focusing on automotive embedded testing, covering:

Automotive electronic testing processes (V model, agile testing);

In-vehicle network testing (CAN, LIN, Ethernet);

Functional safety testing (ISO 26262);

Industry Recognition: Tier 1 suppliers like Continental and Bosch regard CTFL – AUT as a necessary qualification for testing engineers, with certified individuals enjoying a salary premium of 15% – 25%.

2. ASPICE Testing Expert Certification

Certification Highlights: Focused on improving automotive software development processes, ASPICE certification requires testing engineers to master:Requirement-based test case design (100% requirement traceability);Test environment management (hardware-in-the-loop, software-in-the-loop);

Test data management and analysis (generating quality reports using tools like DIADEM);When a car manufacturer recruits a vehicle testing leader, they explicitly require “ASPICE CL3 certification and leading the testing process for more than 3 mass production projects”.

3. Customized Testing Certification by Automotive Manufacturers

Certification Features: Launched by OEMs based on their technical standards, focusing on specific brand testing specifications, such as:Tesla certification requires mastery of its proprietary diagnostic protocols (e.g., Tesla Diagnostics API);Familiarity with Tesla’s FOTA (Full Over-The-Air) testing processes, including upgrade testing for battery management systems and autonomous driving systems;Entering the “fast track” of leading new force car manufacturers, holders of customized certifications are prioritized for core testing positions in companies like Tesla and NIO.

In the era of “exponentially increasing complexity” in automotive embedded software, testing engineers are evolving from “quality verifiers” to “quality designers”. From hardware-in-the-loop testing to cloud-based AI intelligent testing, from functional safety compliance to digital twin-driven approaches, every technological breakthrough is redefining the standards of the “quality gatekeeper”. Only by building full-stack testing capabilities, deeply engaging in practical projects, and anchoring industry-scarce certifications can one occupy an irreplaceable strategic position in the technical blueprint of automotive enterprises.

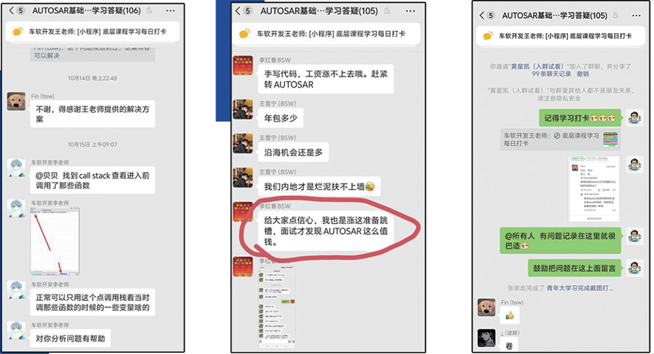

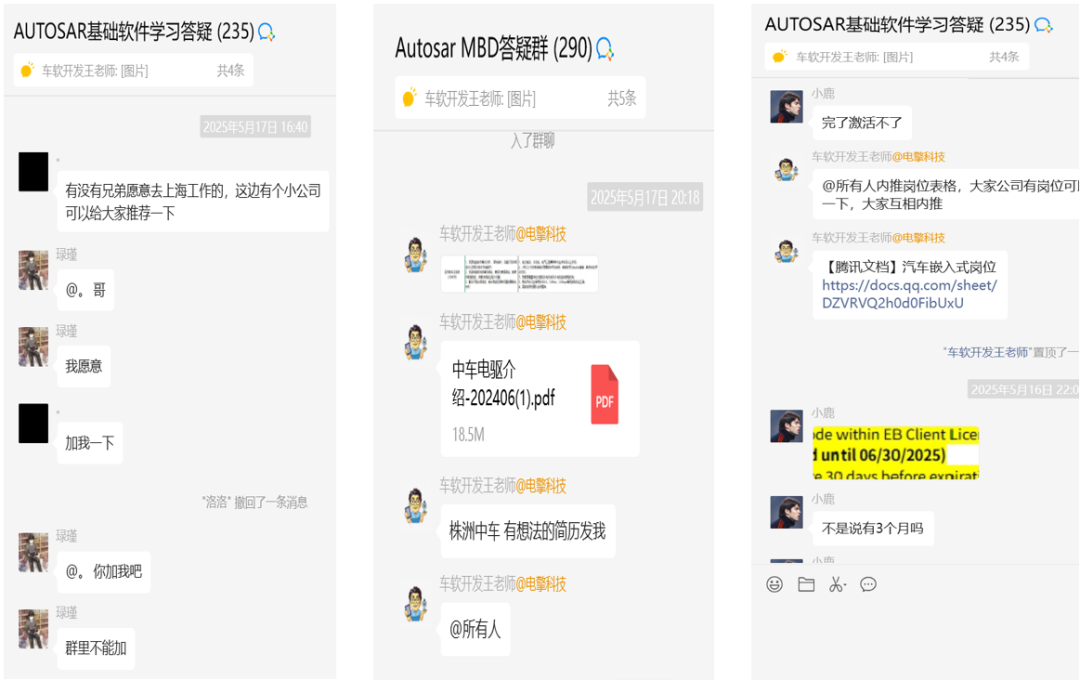

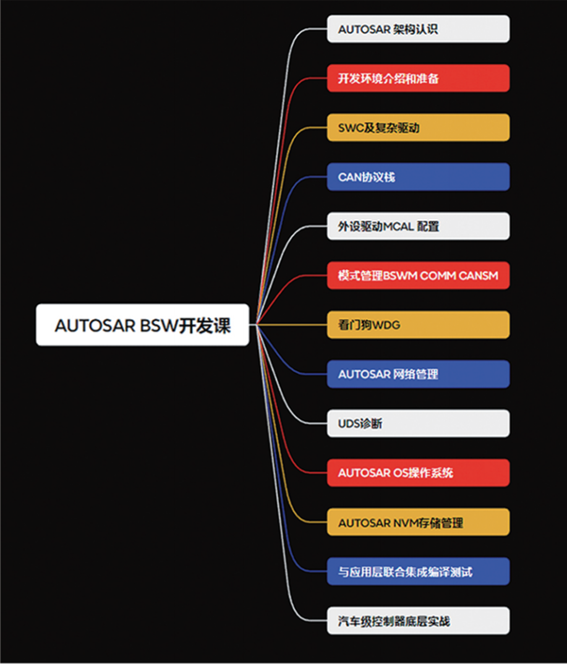

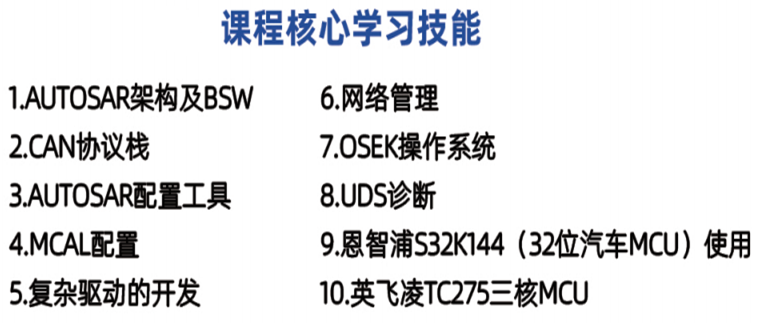

Click on Teacher Wang’s mini-program to learn more about AUTOSAR coursesExplore automotive embedded positions, salaries, etc., waiting for you to discover

Click on Teacher Wang’s mini-program to learn more about AUTOSAR coursesExplore automotive embedded positions, salaries, etc., waiting for you to discover