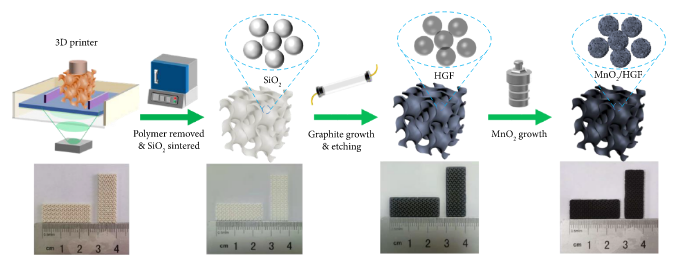

To achieve efficient energy storage devices, 3D printing is being widely applied in the electrochemical field. Recently, a collaborative achievement between the team from Northwestern Polytechnical University and the Additive Manufacturing Laboratory of the National University of Singapore has excited the industry.The joint team utilized two modern industrial technologies, Digital Light Processing (DLP) and Chemical Vapor Deposition (CVD), to develop a unique 3D hollow graphite foam (HGF) with a periodic porous structure and good mechanical properties, successfully achieving high mechanical strength and ultra-high active material loading for electrodes. The results were published in the journal Exploration. “This achievement not only provides a new method for preparing electrode materials with excellent mechanical strength and electrochemical performance but also opens a new path for the large-scale application of advanced energy storage devices,” said Huang Wei, corresponding author of the paper, Academician of the Chinese Academy of Sciences, and Chief Scientist at the Flexible Electronics Frontier Science Center of Northwestern Polytechnical University, in an interview with China Science Daily.Emerging StronglyWith the rapid development of society, the demand for energy is continuously increasing, and there is a desire to find a renewable green energy source. 3D printing can achieve rapid prototyping at relatively low costs, thus attracting significant attention. In recent years, a large number of studies have used 3D printing to create electrodes/devices for electrochemical energy conversion and storage, and experts have made considerable progress in this field, although many challenges and shortcomings still need to be addressed. Since 2018, the team from Northwestern Polytechnical University has been dedicated to developing new types of 3D printed electrodes with higher precision and unique structural designs.

“This achievement not only provides a new method for preparing electrode materials with excellent mechanical strength and electrochemical performance but also opens a new path for the large-scale application of advanced energy storage devices,” said Huang Wei, corresponding author of the paper, Academician of the Chinese Academy of Sciences, and Chief Scientist at the Flexible Electronics Frontier Science Center of Northwestern Polytechnical University, in an interview with China Science Daily.Emerging StronglyWith the rapid development of society, the demand for energy is continuously increasing, and there is a desire to find a renewable green energy source. 3D printing can achieve rapid prototyping at relatively low costs, thus attracting significant attention. In recent years, a large number of studies have used 3D printing to create electrodes/devices for electrochemical energy conversion and storage, and experts have made considerable progress in this field, although many challenges and shortcomings still need to be addressed. Since 2018, the team from Northwestern Polytechnical University has been dedicated to developing new types of 3D printed electrodes with higher precision and unique structural designs. Demonstration of Mechanical Properties of Electrode Materials“Since the establishment of the team, achieving the customization and industrialization of high-performance electrodes through 3D printing technology has been our ongoing goal. By selecting different printing technologies, structural designs, and printing materials, we aim to diversify the customization of electrode materials,” said Professor Guan Cao, corresponding author of the paper and a professor at the Flexible Electronics Research Institute of Northwestern Polytechnical University.Currently, due to the ability of 3D printed electrodes to provide higher active material loading, achieving higher energy density and power density, research on 3D printing technology is gradually heating up in the field of energy storage, including metal-ion batteries, metal-air batteries, and supercapacitors.3D printing technologies include Fused Deposition Modeling (FDM), Inkjet Printing, Selective Laser Melting (SLM), and Stereolithography (SLA).As components that input or output current in conductive media, electrodes have been continuously adjusted in their composition and the chemical reactions they produce over the years to pursue better battery performance. Common electrode materials include metals, metal oxides, metal carbides, metal sulfides, carbon-based materials, conductive polymers, metal-organic frameworks (MOFs), and their composites.Among them, carbon-based materials, such as graphene and carbon nanotubes (CNTs), are one of the most commonly used electrode materials for flexible transparent conductive electrodes (FTCEs), possessing excellent electrical, optical, and mechanical properties. High-quality graphene is widely used in the preparation of FTCEs due to its good conductivity, mechanical flexibility, high optical transparency, and good chemical stability.However, one of the authors of this paper, Professor Ding Jun, leader of the team at the National University of Singapore, stated that there are still certain limitations in the exploration of the practical application of 3D printing technology.Mechanical Stability Above AllCurrently, the main methods for preparing thin-film electrodes using 3D printing technology are extrusion and inkjet methods. Although the working principles of these two methods are quite similar, the properties of the inks used differ significantly. Due to the increasing demand for three-dimensional electrode construction, the preparation of graphene/graphite electrode materials using 3D printing mostly adopts direct-write ink printing methods (extrusion).Due to the relatively low resolution of this technology, typically greater than 200μm, it can only achieve certain simple 3D structures such as grids and interdigitated structures, thus limiting its application. Additionally, for packaging and transportation, the mechanical properties of these 3D carbon materials are also essential, yet previous studies have paid little attention to this aspect.What kind of electrode will be more promising and provide excellent mechanical and electrochemical performance?“Developing new types of 3D printed electrodes with higher precision and unique structural designs will be very promising,” Guan Cao stated. With the help of DLP and CVD, the team designed a lightweight HGF with a simple structure and good porosity. “Finite element calculations and compression tests have shown that the porous HGF with a rotational body structure can effectively prevent structural failure caused by stress concentration, thus maintaining mechanical stability,” Guan Cao explained, emphasizing that mechanical stability is paramount.

Demonstration of Mechanical Properties of Electrode Materials“Since the establishment of the team, achieving the customization and industrialization of high-performance electrodes through 3D printing technology has been our ongoing goal. By selecting different printing technologies, structural designs, and printing materials, we aim to diversify the customization of electrode materials,” said Professor Guan Cao, corresponding author of the paper and a professor at the Flexible Electronics Research Institute of Northwestern Polytechnical University.Currently, due to the ability of 3D printed electrodes to provide higher active material loading, achieving higher energy density and power density, research on 3D printing technology is gradually heating up in the field of energy storage, including metal-ion batteries, metal-air batteries, and supercapacitors.3D printing technologies include Fused Deposition Modeling (FDM), Inkjet Printing, Selective Laser Melting (SLM), and Stereolithography (SLA).As components that input or output current in conductive media, electrodes have been continuously adjusted in their composition and the chemical reactions they produce over the years to pursue better battery performance. Common electrode materials include metals, metal oxides, metal carbides, metal sulfides, carbon-based materials, conductive polymers, metal-organic frameworks (MOFs), and their composites.Among them, carbon-based materials, such as graphene and carbon nanotubes (CNTs), are one of the most commonly used electrode materials for flexible transparent conductive electrodes (FTCEs), possessing excellent electrical, optical, and mechanical properties. High-quality graphene is widely used in the preparation of FTCEs due to its good conductivity, mechanical flexibility, high optical transparency, and good chemical stability.However, one of the authors of this paper, Professor Ding Jun, leader of the team at the National University of Singapore, stated that there are still certain limitations in the exploration of the practical application of 3D printing technology.Mechanical Stability Above AllCurrently, the main methods for preparing thin-film electrodes using 3D printing technology are extrusion and inkjet methods. Although the working principles of these two methods are quite similar, the properties of the inks used differ significantly. Due to the increasing demand for three-dimensional electrode construction, the preparation of graphene/graphite electrode materials using 3D printing mostly adopts direct-write ink printing methods (extrusion).Due to the relatively low resolution of this technology, typically greater than 200μm, it can only achieve certain simple 3D structures such as grids and interdigitated structures, thus limiting its application. Additionally, for packaging and transportation, the mechanical properties of these 3D carbon materials are also essential, yet previous studies have paid little attention to this aspect.What kind of electrode will be more promising and provide excellent mechanical and electrochemical performance?“Developing new types of 3D printed electrodes with higher precision and unique structural designs will be very promising,” Guan Cao stated. With the help of DLP and CVD, the team designed a lightweight HGF with a simple structure and good porosity. “Finite element calculations and compression tests have shown that the porous HGF with a rotational body structure can effectively prevent structural failure caused by stress concentration, thus maintaining mechanical stability,” Guan Cao explained, emphasizing that mechanical stability is paramount. Further coating MnO2 nanosheets on the graphite foam can directly serve as electrode materials for supercapacitors without the need for additional binders and current collectors. Benefiting from its unique hollow porous structure, it not only achieves high-quality loading of active substances but also exhibits significant high surface and volume capacitance.Finite element analysis results confirm that the pre-designed helical porous structure can provide uniform stress regions and mitigate potential structural failure trends caused by stress concentration. Experimental results show that the prepared graphite foam can achieve high mechanical strength at lower material densities. When the surface of the graphite foam is coated with ultra-high loading of MnO2, MnO2/HGF can simultaneously achieve high area, volume, and mass-specific capacitance.

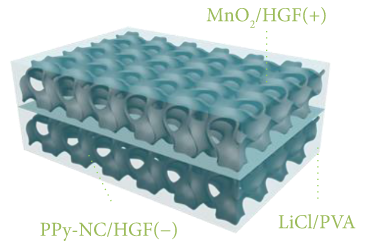

Further coating MnO2 nanosheets on the graphite foam can directly serve as electrode materials for supercapacitors without the need for additional binders and current collectors. Benefiting from its unique hollow porous structure, it not only achieves high-quality loading of active substances but also exhibits significant high surface and volume capacitance.Finite element analysis results confirm that the pre-designed helical porous structure can provide uniform stress regions and mitigate potential structural failure trends caused by stress concentration. Experimental results show that the prepared graphite foam can achieve high mechanical strength at lower material densities. When the surface of the graphite foam is coated with ultra-high loading of MnO2, MnO2/HGF can simultaneously achieve high area, volume, and mass-specific capacitance. Moreover, the assembled quasi-solid asymmetric supercapacitors also demonstrate excellent mechanical and electrochemical performance. This strategy of using three-dimensional porous and robust materials with good mechanical and electrochemical properties will pave the way for the practical application of advanced energy storage devices.Future ExpectationsRegarding future research plans, Huang Wei stated, “In the future, developing multifunctional electrode 3D printing technology, creating suitable 3D printing material systems, and achieving one-step printing of energy storage devices are topics we will continue to explore.”“Discussing the most suitable printing process parameters and structural parameters, promoting the development of energy storage device technology and industry, and achieving the industrialization of new energy storage devices is our ultimate goal,” Huang Wei further explained. As the demand for high specific capacity and high specific power energy storage devices increases, low-cost and easy manufacturing processes will also help 3D printing battery production companies secure a place in the market.”Undoubtedly, durable metal electrodes related to industry remain the preferred material for most prototype devices. Compared to traditional methods, some 3D printed prototype devices show comparable or better performance, from unique electrode structures (such as surface porosity and roughness) to electrochemical battery designs related to printing capabilities.However, systematic research on the differences between different types of 3D printed electrodes and devices using different printing technologies is still lacking, and there remains a significant knowledge gap in this area. Similarly, there is also limited comparative data on traditional systems and industrial systems.Guan Cao believes that with the introduction of China’s “Made in China 2025” development strategy, manufacturing technology will face a historic opportunity for significant upgrades and renewals. 3D printing technology is an effective complement to traditional processing technologies and is a strategically significant technology with epoch-making implications. Currently, the results of 3D printing technology in the field of energy storage are beginning to emerge, with various printing technologies and materials continuously being applied in 3D printing, which will bring opportunities for the development of 3D printing technology in the energy storage field. “It can be believed that with the continuous development of printing technology and materials, 3D printed batteries with good durability, excellent safety, and higher energy density and power density will eventually find widespread application in more fields,” Guan Cao stated.Paper Information:http://spj.sciencemag.org/journals/research/2020/7304767/Source:China Science Daily

Moreover, the assembled quasi-solid asymmetric supercapacitors also demonstrate excellent mechanical and electrochemical performance. This strategy of using three-dimensional porous and robust materials with good mechanical and electrochemical properties will pave the way for the practical application of advanced energy storage devices.Future ExpectationsRegarding future research plans, Huang Wei stated, “In the future, developing multifunctional electrode 3D printing technology, creating suitable 3D printing material systems, and achieving one-step printing of energy storage devices are topics we will continue to explore.”“Discussing the most suitable printing process parameters and structural parameters, promoting the development of energy storage device technology and industry, and achieving the industrialization of new energy storage devices is our ultimate goal,” Huang Wei further explained. As the demand for high specific capacity and high specific power energy storage devices increases, low-cost and easy manufacturing processes will also help 3D printing battery production companies secure a place in the market.”Undoubtedly, durable metal electrodes related to industry remain the preferred material for most prototype devices. Compared to traditional methods, some 3D printed prototype devices show comparable or better performance, from unique electrode structures (such as surface porosity and roughness) to electrochemical battery designs related to printing capabilities.However, systematic research on the differences between different types of 3D printed electrodes and devices using different printing technologies is still lacking, and there remains a significant knowledge gap in this area. Similarly, there is also limited comparative data on traditional systems and industrial systems.Guan Cao believes that with the introduction of China’s “Made in China 2025” development strategy, manufacturing technology will face a historic opportunity for significant upgrades and renewals. 3D printing technology is an effective complement to traditional processing technologies and is a strategically significant technology with epoch-making implications. Currently, the results of 3D printing technology in the field of energy storage are beginning to emerge, with various printing technologies and materials continuously being applied in 3D printing, which will bring opportunities for the development of 3D printing technology in the energy storage field. “It can be believed that with the continuous development of printing technology and materials, 3D printed batteries with good durability, excellent safety, and higher energy density and power density will eventually find widespread application in more fields,” Guan Cao stated.Paper Information:http://spj.sciencemag.org/journals/research/2020/7304767/Source:China Science Daily

Note: Images are sourced from the internet; please notify for removal if there are any copyright issues!