As artificial intelligence (AI) continues to play a central role in data center operations, the demand for efficient and high-performance power solutions is becoming increasingly important.AI workloads require substantial computational resources, leading to increased power consumption and heat generation.These challenges necessitate innovative approaches in power data conversion and distribution, focusing on optimizing electronic components such as power management ICs, converters, gate drivers, and power MOSFETs.Trends Driving AI Data Center Power SolutionsAI data centers are undergoing rapid transformation to meet the demands of increasingly complex workloads. Key trends influencing the development of power solutions include higher bus voltages, advanced point-of-load (POL) power delivery architectures, and the integration of advanced power management devices. These advancements aim to enhance energy efficiency, reduce thermal challenges, and support the scalability required for next-generation AI applications.Increasing Bus Voltage to Reduce LossesOne of the most significant trends in data center power design is the shift towards higher bus voltages, such as transitioning from 12V to 48V or even higher. This shift addresses several inefficiencies inherent in traditional low-voltage systems:

- Reduced Current: Higher voltage systems require less current to deliver the same power, significantly reducing resistive losses in conductors and connectors, as well as the heat generated.

- Increased Power Density: Lower current translates to smaller, more efficient distribution devices, achieving higher power density and minimizing space requirements.

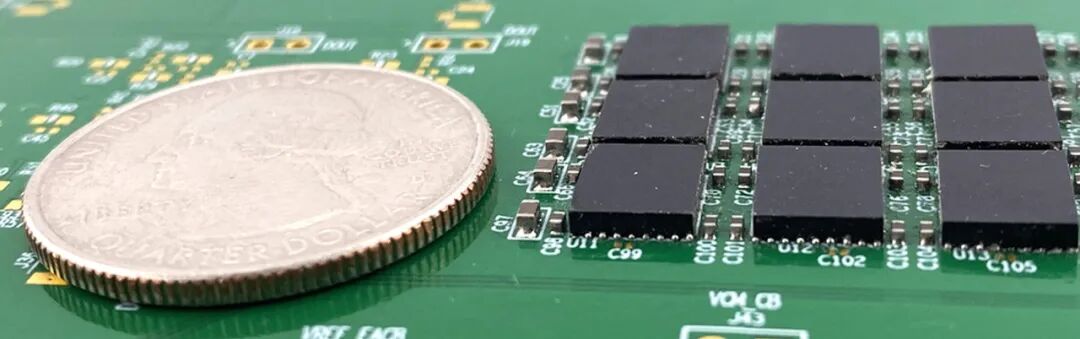

In distribution systems for applications such as data centers and servers, intermediate bus converters (IBCs) are becoming increasingly popular.These are DC/DC converters used to step down the high voltage (e.g., 48V or 400V) from a central power source to an intermediate voltage (e.g., 12V or 8V) distributed throughout the system.This intermediate voltage is further converted at the POL to lower voltages to power various components.Modern IBCs are highly efficient, often exceeding 95%, minimizing energy loss and thermal issues. They are compact and can be installed in dense electronic systems, typically providing electrical isolation between input and output, enhancing safety and reducing noise propagation.Flex Power Modules recently launched two non-isolated, non-regulated IBCs designed to power data centers for AI, machine learning, and cloud applications. The BMR321 (Figure 1) features a fixed 8:1 conversion ratio, enabling efficient step-down from 40-60V to 5-7.5V. It provides 750W of continuous power output and can handle peak power up to 1,500W. Additionally, this DC/DC power converter achieves peak efficiency of over 98% while maintaining a compact size compliant with the Open Compute Project (OCP) standard OAM v2.0. Figure 1: Flex’s BMR321 IBC. (Source: Flex Power Modules)The BMR316 is designed with a fixed 4:1 conversion ratio, effectively stepping down 48V to 12V. It provides 1kW of continuous power output and supports peak power output up to 3kW. The BMR316 achieves a power density exceeding 900W/cm3 at peak load, utilizing a compact package measuring only 23.4×17.8×7.65mm. Its input voltage range is 38-60V (with a peak of 68V), and the output voltage range is 9.5-15V.POL Power OutputThe growing power demands of AI data centers pose significant challenges across the entire power conversion chain, from AC/DC power supplies to POL stages located directly next to processors.AI relies on massively parallel computing, utilizing architectures such as graphics processing units (GPUs) and tensor processing units. These processors feature hundreds of cores and high-bandwidth memory, either integrated on a single chip or configured in a stacked die arrangement using chip-on-wafer-on-substrate (CoWoS) technology within the same package.For these applications, Infineon Technologies has introduced the TDM2254xD power module series (Figure 2). These modules are designed to provide efficient voltage management for high-performance computing platforms by enhancing electrical, thermal, and mechanical performance, supporting the vision of green AI factories.The module features a unique design that facilitates effective thermal conduction from the power stage to the heatsink through a dedicated inductor configuration. This design optimizes current and heat transfer, achieving a 2% efficiency improvement over industry-standard modules at full load. Infineon states that improving power efficiency for GPU cores can significantly save energy, resulting in several megawatts of power savings for data centers generating compute-intensive AI workloads.

Figure 1: Flex’s BMR321 IBC. (Source: Flex Power Modules)The BMR316 is designed with a fixed 4:1 conversion ratio, effectively stepping down 48V to 12V. It provides 1kW of continuous power output and supports peak power output up to 3kW. The BMR316 achieves a power density exceeding 900W/cm3 at peak load, utilizing a compact package measuring only 23.4×17.8×7.65mm. Its input voltage range is 38-60V (with a peak of 68V), and the output voltage range is 9.5-15V.POL Power OutputThe growing power demands of AI data centers pose significant challenges across the entire power conversion chain, from AC/DC power supplies to POL stages located directly next to processors.AI relies on massively parallel computing, utilizing architectures such as graphics processing units (GPUs) and tensor processing units. These processors feature hundreds of cores and high-bandwidth memory, either integrated on a single chip or configured in a stacked die arrangement using chip-on-wafer-on-substrate (CoWoS) technology within the same package.For these applications, Infineon Technologies has introduced the TDM2254xD power module series (Figure 2). These modules are designed to provide efficient voltage management for high-performance computing platforms by enhancing electrical, thermal, and mechanical performance, supporting the vision of green AI factories.The module features a unique design that facilitates effective thermal conduction from the power stage to the heatsink through a dedicated inductor configuration. This design optimizes current and heat transfer, achieving a 2% efficiency improvement over industry-standard modules at full load. Infineon states that improving power efficiency for GPU cores can significantly save energy, resulting in several megawatts of power savings for data centers generating compute-intensive AI workloads. Figure 2: Infineon’s TDM2254xD dual-phase power module. (Source: Infineon Technologies)For AI and high-performance computing, Empower Semiconductor has launched the AI power platform Crescendo, aimed at enhancing efficiency and performance in AI data centers. Unlike traditional horizontal power systems, Crescendo employs vertical power delivery, supplying power directly to AI chips. This innovative approach eliminates the need for bulky bypass capacitors and reduces power delivery losses by up to 10%, resulting in a more streamlined and efficient design.The platform also integrates Empower’s proprietary FinFast technology, providing high-speed, high-precision, and high-efficiency power. It ensures precise and responsive power regulation even under the most demanding AI workloads.

Figure 2: Infineon’s TDM2254xD dual-phase power module. (Source: Infineon Technologies)For AI and high-performance computing, Empower Semiconductor has launched the AI power platform Crescendo, aimed at enhancing efficiency and performance in AI data centers. Unlike traditional horizontal power systems, Crescendo employs vertical power delivery, supplying power directly to AI chips. This innovative approach eliminates the need for bulky bypass capacitors and reduces power delivery losses by up to 10%, resulting in a more streamlined and efficient design.The platform also integrates Empower’s proprietary FinFast technology, providing high-speed, high-precision, and high-efficiency power. It ensures precise and responsive power regulation even under the most demanding AI workloads.

With its compact, ultra-slim profile (Figure 3), Crescendo maximizes space utilization in data centers. Its high-density design allows for seamless integration, providing the power density and performance required to support the growing demands of AI infrastructure.

Figure 3: Empower’s Crescendo power platform. (Source: Empower Semiconductor)Advancements in Power SemiconductorsMicrochip’s IGBT 7 product line represents one of the latest advancements in silicon devices. It offers a variety of package options, topologies, and current and voltage ranges, specifically designed to meet the growing power demands of data centers. These modules reduce collector-emitter saturation voltage and forward voltage of the freewheeling diode, thereby minimizing conduction and switching losses and improving energy efficiency. Their thermal performance has also been enhanced, maintaining overload capability at junction temperatures up to 175°C, allowing them to operate reliably in harsh environments.Performance improvements also include a 50% increase in current handling capability, making them highly suitable for modern high-power applications. Enhanced dynamic voltage (dv/dt) controllability reduces electromagnetic interference (EMI) and switching losses, while the improved softness of the freewheeling diode ensures smooth transitions during switching, reducing system stress and enhancing reliability. Additionally, these modules simplify drive requirements, streamline integration, and reduce design complexity compared to traditional products.New power conversion technologies such as gallium nitride (GaN) and silicon carbide (SiC) devices also play a crucial role in supporting high-voltage operation. Compared to traditional silicon-based devices, these wide bandgap (WBG) materials exhibit lower switching losses and higher thermal conductivity, enabling converters and gate drivers to operate efficiently at higher voltages.The adoption of GaN and SiC power modules and discrete devices is revolutionizing the power landscape of AI data centers. Key advantages include:

Figure 3: Empower’s Crescendo power platform. (Source: Empower Semiconductor)Advancements in Power SemiconductorsMicrochip’s IGBT 7 product line represents one of the latest advancements in silicon devices. It offers a variety of package options, topologies, and current and voltage ranges, specifically designed to meet the growing power demands of data centers. These modules reduce collector-emitter saturation voltage and forward voltage of the freewheeling diode, thereby minimizing conduction and switching losses and improving energy efficiency. Their thermal performance has also been enhanced, maintaining overload capability at junction temperatures up to 175°C, allowing them to operate reliably in harsh environments.Performance improvements also include a 50% increase in current handling capability, making them highly suitable for modern high-power applications. Enhanced dynamic voltage (dv/dt) controllability reduces electromagnetic interference (EMI) and switching losses, while the improved softness of the freewheeling diode ensures smooth transitions during switching, reducing system stress and enhancing reliability. Additionally, these modules simplify drive requirements, streamline integration, and reduce design complexity compared to traditional products.New power conversion technologies such as gallium nitride (GaN) and silicon carbide (SiC) devices also play a crucial role in supporting high-voltage operation. Compared to traditional silicon-based devices, these wide bandgap (WBG) materials exhibit lower switching losses and higher thermal conductivity, enabling converters and gate drivers to operate efficiently at higher voltages.The adoption of GaN and SiC power modules and discrete devices is revolutionizing the power landscape of AI data centers. Key advantages include:

- High Switching Speed: Wide bandgap devices enable faster switching frequencies, allowing for smaller inductors and capacitors in power converters.

- Improved Thermal Performance: With lower conduction and switching losses, these materials achieve higher power density without compromising reliability.

- Wider Voltage Range: GaN and SiC devices are well-suited for the increasing bus voltages in modern data centers.

A recent example is Navitas Semiconductor’s 8.5kW power supply (PSU), claimed to be the industry’s first power supply for next-generation AI and hyperscale data centers. This power supply combines GaN and SiC technologies, achieving efficiency levels of up to 98%.This AI-optimized 54V output power supply complies with OCP and Open Rack v3 specifications, utilizing three-phase interleaved power factor correction (PFC) and LLC topology with high-power GaNSafe power ICs and third-generation fast SiC MOSFETs to deliver maximum efficiency and performance with minimal component count.Digital Power ManagementDigital power control is increasingly recognized as a means of real-time optimization of power delivery. This technology offers the following advantages:

- dv/dt Expansion: Adjusting voltage levels based on workload requirements maximizes efficiency.

- Remote Monitoring: Continuous monitoring of power metrics enables predictive maintenance and provides operational insights.

- Adaptive Control Algorithms: These algorithms ensure optimal operation under varying load conditions, enhancing overall power stability and efficiency.

Navitas Semiconductor has also developed proprietary IntelliWeave digital control technology, which integrates high-power GaNSafe power ICs and third-generation fast SiC MOSFETs, specifically designed for AI data center power. The digital control technology integrated with high-power GaNSafe power ICs has been tested on a 500kHz GaN interleaved 3.2kW critical conduction mode PFC power supply, achieving peak efficiency of 99.3%, including losses from the EMI filter, with a 30% reduction in power loss compared to current solutions.Advancements in Thermal ManagementAs the power consumption of high-performance processors and high-density hardware configurations generates significant heat, advanced thermal management is crucial. Effective thermal management ensures that components operate within safe temperature ranges, preventing overheating, reducing power losses, improving system efficiency, and maintaining optimal performance.Axiado’s Dynamic Thermal Management (DTM) solution is an example, provided by the AI-driven hardware platform security solution provider. The DTM solution is supported by Axiado’s Trusted Control/Compute Unit (TCU). By leveraging the TCU (a secure SoC with built-in AI), the DTM solution allows AI-driven data centers to dynamically adjust cooling based on real-time server workloads, reducing energy consumption. This advanced thermal management technology optimizes cooling, significantly saving costs while supporting AI data centers in achieving carbon-neutral operations.Higher bus voltages, efficient POL transmission, and the adoption of wide bandgap semiconductors are hallmarks of the evolution of power electronics technology in AI data centers. As the demand for computational power continues to rise, these trends will ensure sustainability in energy efficiency and performance, paving the way for future AI-driven innovations.(Editor: Franklin)

Hot Articles

Huawei Releases L3, Responsibility Definition Shifts from “Driver Full Responsibility” to “Shared Responsibility between Manufacturer and User”

2025-04-30

Analysis of 2024 Financial Reports of Domestic MCU Companies: Consumer Electronics Recovery, Automotive Standards Still Burning Cash

2025-04-29

Intel CEO’s Internal Letter: Cut Processes, Cut Layers, Bet on Technology

2025-04-28

South Korea’s “National Treasure” Semiconductor Expert Takes Office in China

2025-04-27

Dissecting a 7kW Home Electric Vehicle Charging Pile: Engineering Design is Complex

2025-04-26