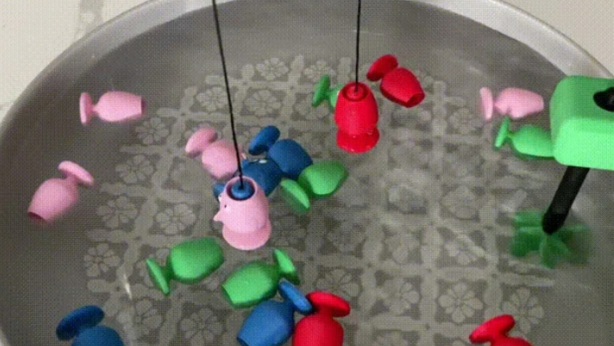

01 Fish-Friendly Fishing Set

This magnetic fishing toy set won the MakerWorld Maker Beginner Kit Design Competition. The project consists of two parts: on one hand, there are fish and fishing rods; on the other hand, there is a blender that you can use to create waves in the “pond.” This means that if you don’t want to bother making the blender, you can choose a simpler (but still fun!) way to fish.

Download link:

https://makerworld.com/zh/models/938424-magnetic-fishing-toy-set#profileId-903673

02 Watering Can

02 Watering Can

Use this 3D printed watering can to water your plants. If you only have one or two small plants, and you don’t want a watering can that takes up too much space or requires a large capacity, this design might be just right for you.

Download link:

https://makerworld.com/zh/models/19929-tear-drop-watering-can?from=search#profileId-18551

03 Harris Tweed

03 Harris Tweed

Harris Tweed integrates affordable 3D printing technology with parts realized through CAD software, incorporating this centuries-old craft.

Harris Tweed fabric is exported to over 60 countries worldwide, and this iconic textile has been used by some of the most renowned brands in fashion, including Dior, Ralph Lauren, and Vivienne Westwood.

Of course, the application of 3D printing technology lies in the loom. The complex design of the loom means that replacing parts can take up to six months to procure, often forcing weavers to borrow parts from fellow craftsmen or modify their looms to keep them running. 3D printing technology was born to solve this problem.

The Harris Tweed Loom Spares Co. has collaborated with the National Manufacturing Institute Scotland (NMIS) to create a new loom assembly design that includes 3D printed parts to improve the convenience of obtaining parts for weavers.

“When a key component of the loom breaks, production can stop for weeks, which is very frustrating,” said Benny. “Finding a way to keep the loom running smoothly is crucial, and being one of the first to trial the new 3D printed components is fantastic. Being able to get the parts we need when we need them will make a huge difference, as it means we can minimize downtime and focus on work without unnecessary interruptions.”

A key assembly component, previously made up of seven separate parts, has been redesigned to use three parts made from robust composite materials through additive manufacturing. The new 3D printed version costs 99% less than the original and can be produced locally in just two hours using low-cost desktop equipment.

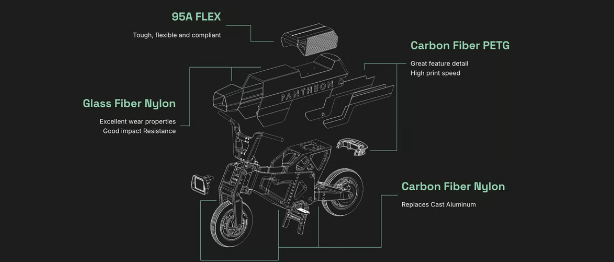

04 Pantheon

04 Pantheon

This Canadian 3D printing startup has printed all structural components of a fully functional motorcycle – and the viral video proves it has withstood the test of riding.

Founders and engineers Alex Wiecke and Bob Cao expressed their frustration with previous software work, dreaming of creating things in the real world rather than just on screen.

One day, they opened a motorcycle shop in their backyard and started hands-on practice, which led them to use 3D printing as a manufacturing tool to produce automotive parts. This path led them to design and manufacture their own 3D printers, materials, and software for their projects, creating the largest and strongest components. Eventually, they founded a product development company and attracted a creative team of hardware engineers. They utilize 3D printing technology to develop and manufacture medical devices, build concept cars, and create mechatronic systems for the film industry.

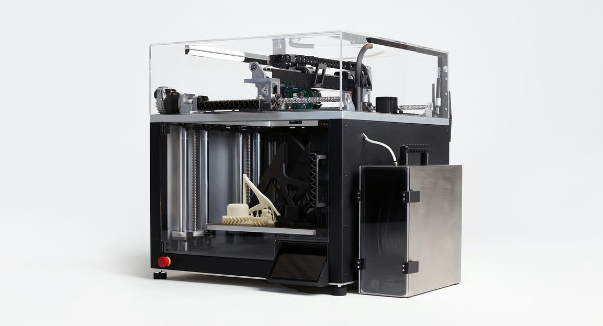

The Pantheon HS-Pro 3D printer launched this month is a high-speed, industrial-grade FDM (Fused Deposition Modeling) 3D printer designed for the rapid production of robust end-use parts. It is designed and manufactured in Canada, emphasizing speed, precision, and durability, making it suitable for demanding applications in automotive, aerospace, and manufacturing sectors.

Pantheon has even developed its own slicing software. Pantheon Slicer is compatible with Mac and Windows systems, runs locally, has no seat limits, and does not require login. The company claims its “multithreading” slicing feature fully utilizes the performance of the user’s computer, meaning large projects can be easily iterated. The software also provides a complete set of G-code visualization and analysis tools, accurately displaying the printer’s operations.

05 Footwear

05 Footwear

3D printed comfortable ergonomic shoes, CGI rubber/silicone shoes.

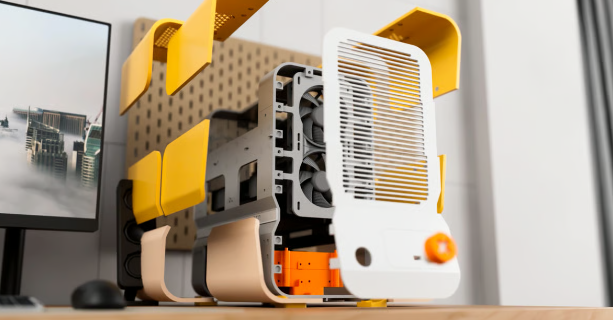

06 MK01

06 MK01

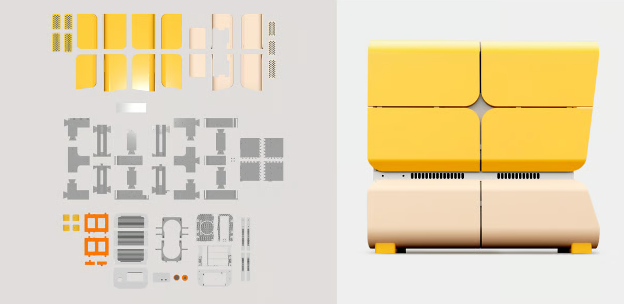

The MK01, designed by French design company Makeyo Studio, is a fully 3D printable mid-tower computer case that reimagines the look and feel of desktop cases. With its rounded edges, magnetic panels, arcade-style power button, and Lego-like modular design, the MK01 is not just a case – it is a personal statement that you can 3D print yourself.

Its designers describe the MK01 as “toyetic” – a term borrowed from the toy industry to describe designs that are both fun and highly customizable – the MK01 aims to inject fun into what is typically a function-over-form component. The case is designed with customization in mind, allowing users to easily change colors, redesign panels, and even mix and match different structural shapes without starting from scratch.

Thanks to its modular and magnetic design, the outer panels of the case can be easily snapped on and off for quick style changes or upgrades. The internal parts fit together like a puzzle and are secured with screws and magnets. This not only provides a practical solution for DIY builders but also fulfills the dreams of makers and modifiers who want to experiment.

File link:

https://www.printables.com/model/1283168-pc-case-mini-itx-micro-atx-design-by-makeyo

END

END

Welcome to add the editor’s WeChatto learn about the latest trends in the 3D printing industry

Welcome to add the editor’s WeChatto learn about the latest trends in the 3D printing industry

About 3D Printing Technology

About 3D Printing Technology

We integrate insights, technology trends, application scenarios, competitive strategies, and in-depth dynamics from the 3D printing and AI industries in China, the US, and globally, providing high-value information. We are passionate about 3D printing and welcome contributors from around the world.

Disclaimer:3D Printing Technology has no commercial cooperation, sponsorship, employment, or other interests with the companies mentioned in the text.3D Printing TechnologyImages and videos from the internet are for auxiliary reading purposes only, with no commercial intent.All rights belong to the original authors. If there are any infringement actions, please contact the rights holders, and we will delete them promptly. The copyright of the images in this article belongs to the copyright holders,3D Printing Technologywatermarks are automatically added for auxiliary reading and do not represent ownership of the images. For image usage, please consult the copyright holders.3D Printing TechnologyThe article does not constitute any investment advice,3D Printing Technologyis not responsible for any direct or indirect losses caused by the use of the information in this article.