Communicating with Weighing Instruments via MODBUS with S7-200 SMART

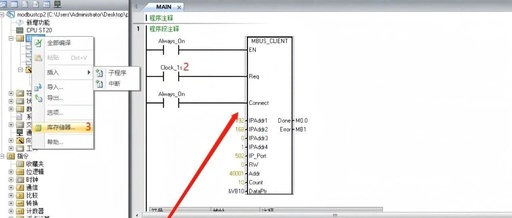

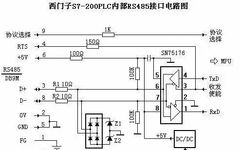

Click↑↑Technical Training, follow and pin it to subscribe for free long-term 200,000+ industrial control personnel follow this WeChat platform: technical sharing, learning exchange, industrial control videos First, let’s introduce our hardware preparation 1 A weighing instrument that supports Modbus protocol Weighing instrument that supports Modbus protocol 2 Set up the communication parameters of the instrument … Read more