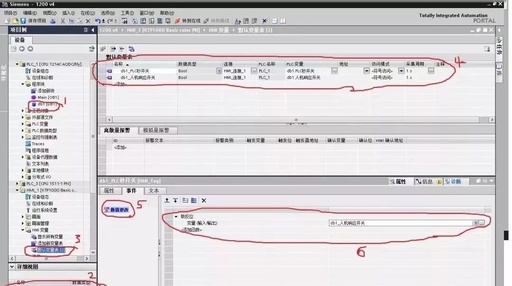

Can Wireless Ethernet Communication Be Achieved Between Touch Screens and Siemens PLCs?

WeChat Search Technical Training In practical production, it is often encountered that when a PLC cannot meet the process requirements, such as insufficient high-speed pulse channels or insufficient analog input/output channels, replacing with a larger PLC will significantly increase costs. At this time, it can be considered to use multiple PLCs to work together to … Read more