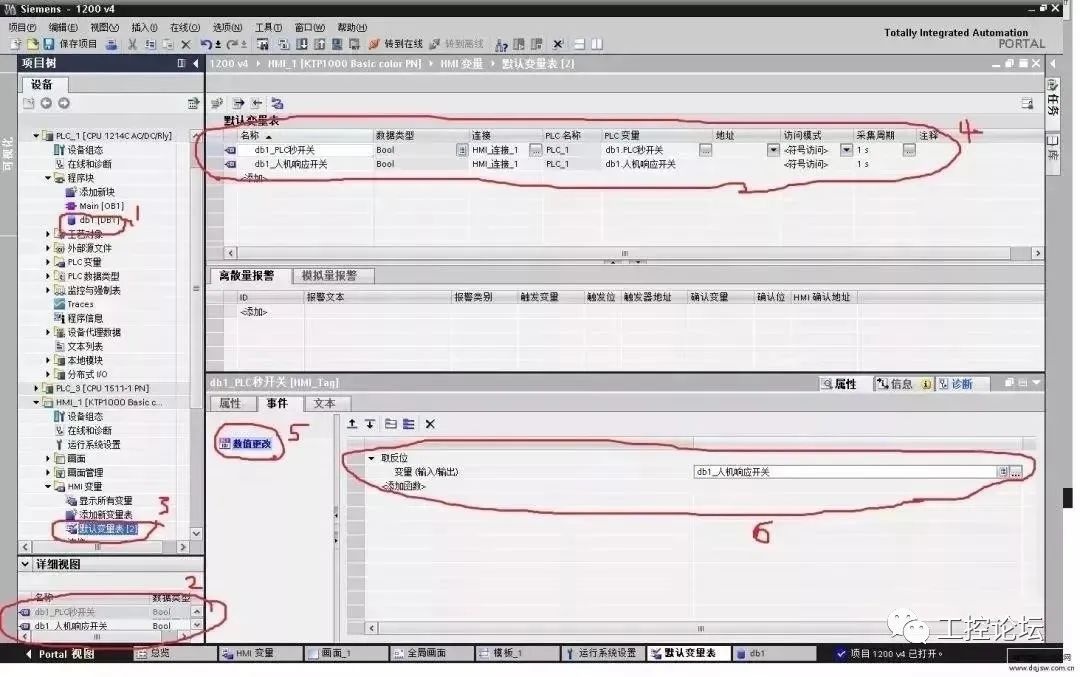

For example, see the image, and follow these steps:

1

First, check the parameters

2

Online Simulation

3

Test the Wiring

1. Latest Complete Electrical Engineering Question Bank (National Version) 2021

2. Electrical Expert’s Private Tool Kit (Electrical Simulation Software + 16 Sets of Electrical Industry PPT)

3. Master says: If you don’t know CAD, don’t think about becoming an electrical engineer (with CAD software package)