Skip to content

The following example connects the MT6103IP touch screen to a Panasonic PLC; other brands of PLCs can be referenced.

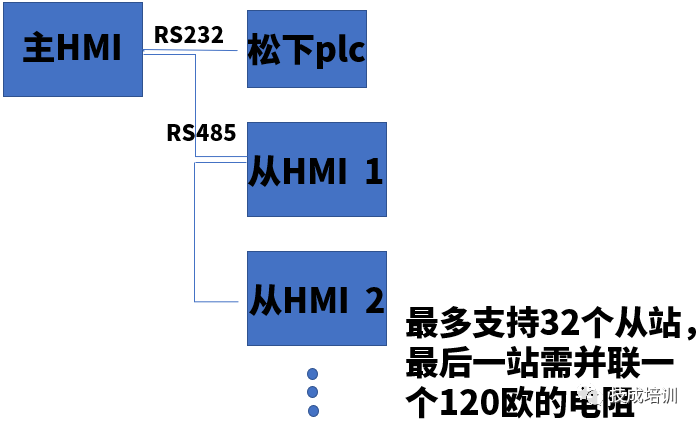

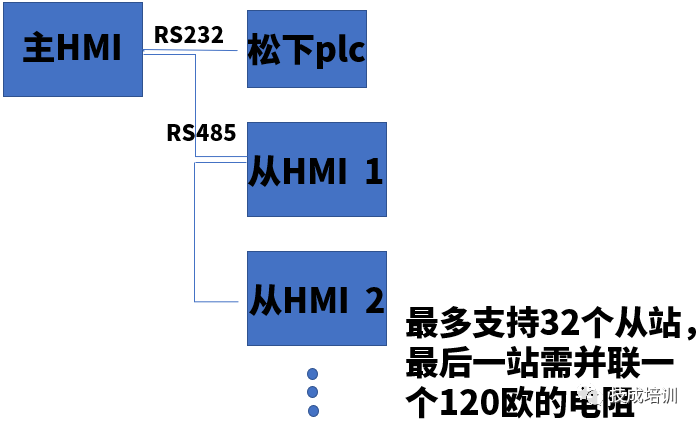

1. Determine the connection scheme as follows:

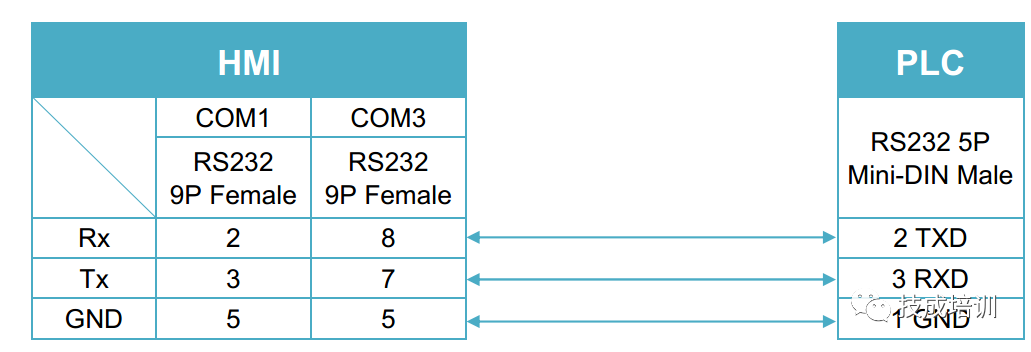

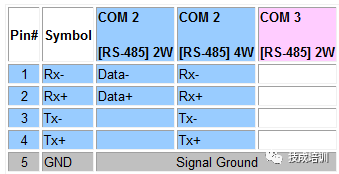

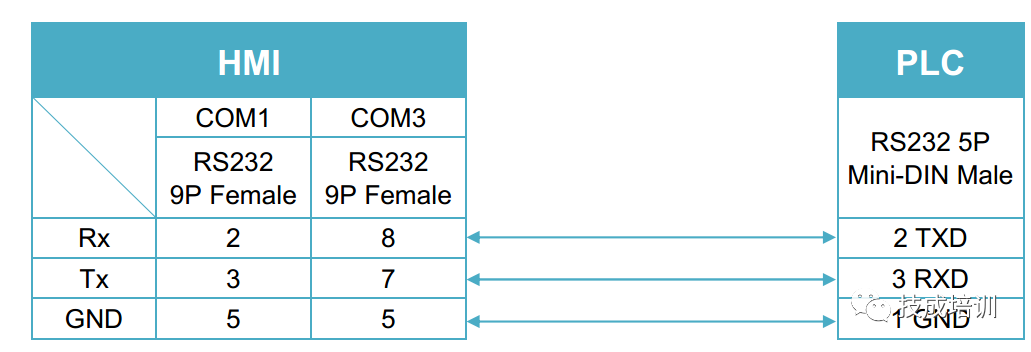

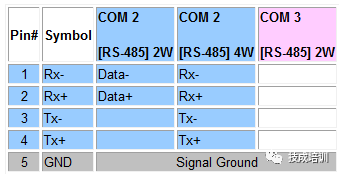

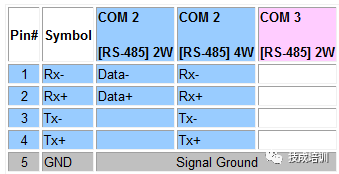

Below are the wiring terminals of the touch screen, which has 9 pins, allowing for one group of RS232 and another group of RS485.

1) RS232 is used to connect to the PLC (COM1)

Main Touch Screen Panasonic PLC

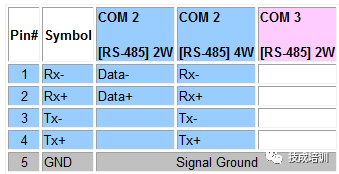

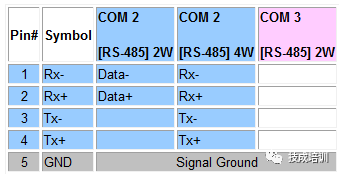

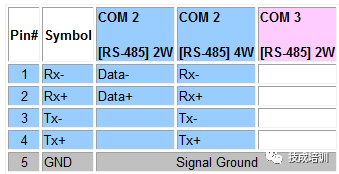

2) RS485 is used for connections between touch screens (COM2)

Main Touch Screen Slave Screen 1

All touch screens’ pin 1 are connected together, pin 2 are also connected together, and the last touch screen has pins 1 and 2 connected to a 120-ohm resistor.

3. Screen parameter settings

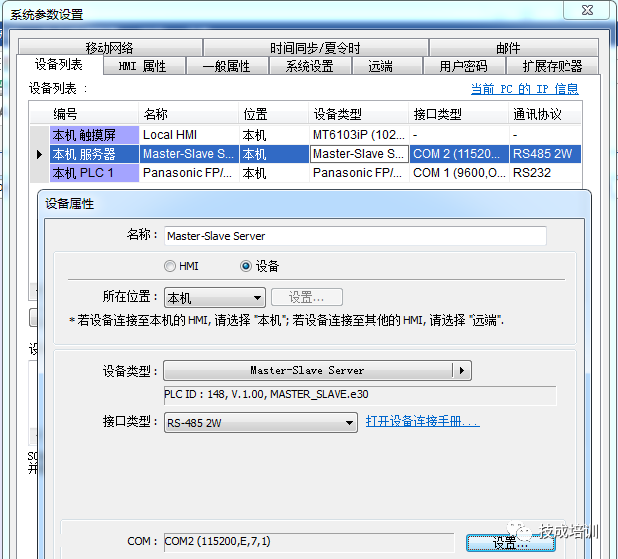

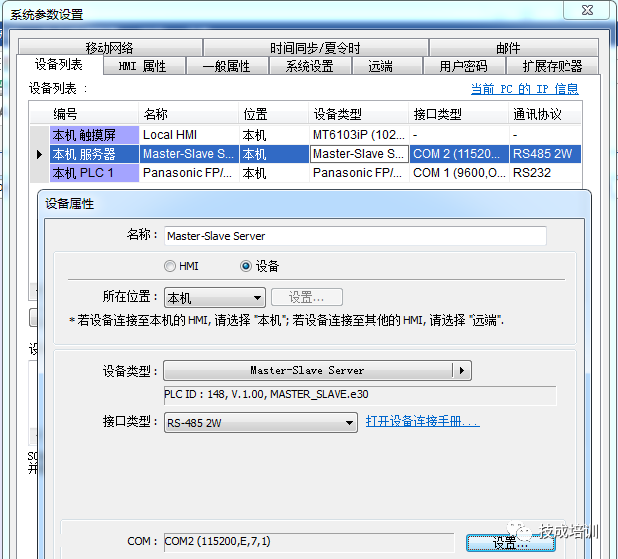

Open the Weilan software, create a new file, and add the host server to serve as the link between the main touch screen and the slave screens, using RS485, select CON2 (this port is used for the connection of the second touch screen), add the local PLC (connected to the Panasonic PLC), use 232 communication to select CON1, and set the station number in the HMI properties to 0, keeping other parameters default.

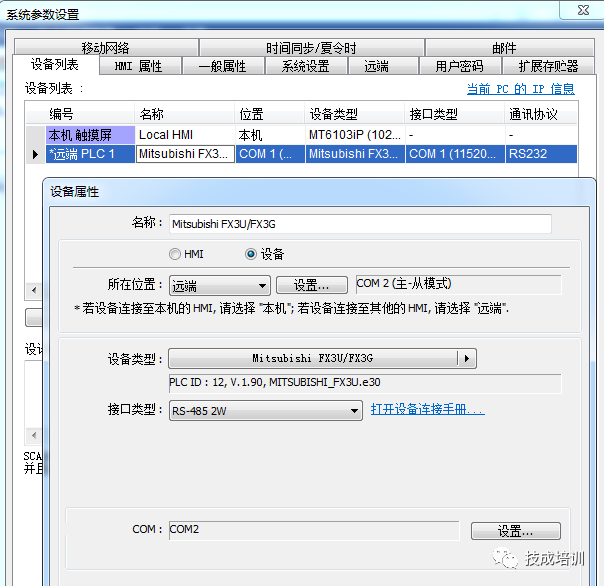

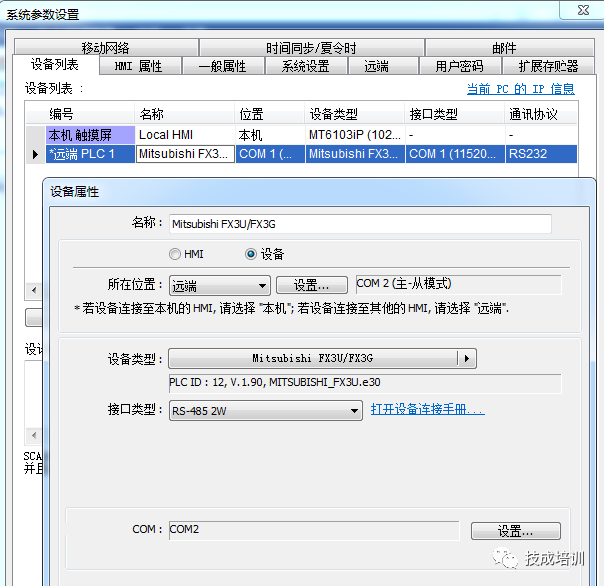

Create a new program for the slave screen, which can be multiple, with station numbers set to 1, 2, 3. Each slave screen only has a different station number; other parameters are system defaults… Add the remote PLC, select remote (because it is connected through other screens as a link), main-slave mode, select COM2 for RS485 communication, and ensure the communication settings are consistent with the main screen’s server settings, keeping other parameters default.

Once the above is completed, communication between one PLC and multiple Weilan touch screens can be achieved.

Original from Jicheng Training Network, Author:Chen Yuxin

Unauthorized reproduction is prohibited, violators will be prosecuted!

The following example connects the MT6103IP touch screen to a Panasonic PLC; other brands of PLCs can be referenced.

1. Determine the connection scheme as follows:

Below are the wiring terminals of the touch screen, which has 9 pins, allowing for one group of RS232 and another group of RS485.

1) RS232 is used to connect to the PLC (COM1)

Main Touch Screen Panasonic PLC

2) RS485 is used for connections between touch screens (COM2)

Main Touch Screen Slave Screen 1

All touch screens’ pin 1 are connected together, pin 2 are also connected together, and the last touch screen has pins 1 and 2 connected to a 120-ohm resistor.

3. Screen parameter settings

Open the Weilan software, create a new file, and add the host server to serve as the link between the main touch screen and the slave screens, using RS485, select CON2 (this port is used for the connection of the second touch screen), add the local PLC (connected to the Panasonic PLC), use 232 communication to select CON1, and set the station number in the HMI properties to 0, keeping other parameters default.

Create a new program for the slave screen, which can be multiple, with station numbers set to 1, 2, 3. Each slave screen only has a different station number; other parameters are system defaults… Add the remote PLC, select remote (because it is connected through other screens as a link), main-slave mode, select COM2 for RS485 communication, and ensure the communication settings are consistent with the main screen’s server settings, keeping other parameters default.

Once the above is completed, communication between one PLC and multiple Weilan touch screens can be achieved.

Original from Jicheng Training Network, Author:Chen Yuxin

Unauthorized reproduction is prohibited, violators will be prosecuted!

Free PLC and Electrical Courses, click to read the original text

The following example connects the MT6103IP touch screen to a Panasonic PLC; other brands of PLCs can be referenced.

The following example connects the MT6103IP touch screen to a Panasonic PLC; other brands of PLCs can be referenced.

The following example connects the MT6103IP touch screen to a Panasonic PLC; other brands of PLCs can be referenced.

The following example connects the MT6103IP touch screen to a Panasonic PLC; other brands of PLCs can be referenced.