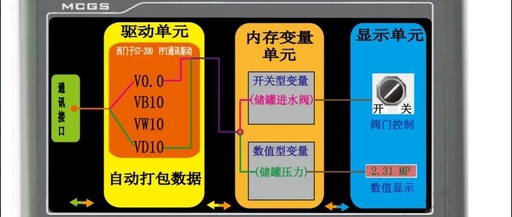

How to Communicate Between Touch Screen and PLC?

Click the blue text Follow us In practical control projects centered around PLCs, most of the time, we cannot do without the cooperation of touch screens or upper computers. This is because we use PLCs for control, mainly to process some analog quantities that we need to monitor, such as pressure, temperature, flow, and other … Read more