In practical production, it is often encountered that when a PLC cannot meet the process requirements, such as insufficient high-speed pulse channels or insufficient analog input/output channels, replacing with a larger PLC will significantly increase costs. At this time, it can be considered to use multiple PLCs to work together to meet complex process requirements, so how can multiple PLCs communicate conveniently and efficiently?

In actual systems, multiple PLCs are distributed in the same workshop, controlled centrally by a touch screen. Usually, all devices are spaced from dozens to hundreds of meters apart. When communication is required, wiring can be cumbersome and unsightly, making wireless communication a suitable option.

This solution uses MCGS touch screens and two Siemens S7-200SMART PLCs as examples to introduce the process of wireless S7 protocol communication between the touch screen and multiple PLCs. In this solution, the Siemens PLC wireless communication terminal DTD418M is used as the hardware device to achieve wireless communication.

In this solution, users do not need to change network parameters or the original program, nor do they need to understand the details of the S7 protocol. By using the dedicated wireless communication terminal for European and American PLCs—DTD418M, they can directly replace wired Ethernet communication between the touch screen and PLC, and stably and conveniently achieve wireless Ethernet communication under the S7 protocol.

Wireless Network Diagram ▼

● Siemens PLC Model: S7-200Smart × 2 units

● Touch Screen: MCGS-TPC7031KT × 1 unit

● Communication Device: DTD418MA × 3 units

● Master-Slave Relationship: 1 Master 2 Slaves

● Communication Interface: RJ45 Interface

● Communication Protocol: S7 Protocol

● Transmission Distance: 100 meters, 1KM

◆ Can directly replace wired Ethernet to achieve wireless networking;

◆ Supports Siemens S7 protocol, PROFINET protocol, MODBUS TCP/IP protocol, etc.;

◆ Fully digital wireless encrypted transmission method, no card insertion and no operating costs;

◆ No need to change the program, plug and play, self-adaptive interface protocol;

◆ Can work in various harsh industrial environments.

1. Wiring between Touch Screen and DTD418M

Use a communication cable, one end connects to the RJ45 interface of DTD418M, the other end connects to the RJ45 interface of the MCGS touch screen.

2. Wiring between PLC and DTD418M

Use a communication cable, one end connects to the RJ45 interface of DTD418M, the other end connects to the RJ45 interface of S7-200SMART.

1. File – New Project;

2. Device Window – Device Toolbox – General TCP/IP Device – SMART200 Ethernet;

3. Set IP Address;

4. Add variables for each device;

5. Screen Production;

1. New Project, as shown below;

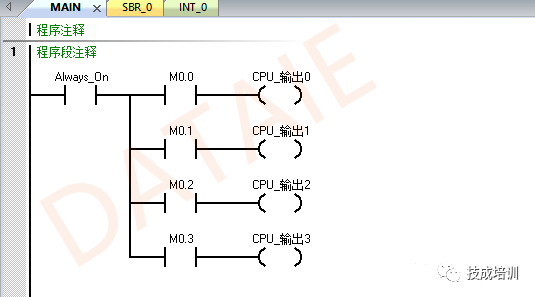

2. Simple Program Writing;

Drive the Q point output with the M point response.

3. Click Download – All – Find CPU;

4. Click Download;

Set the IPs of the two PLCs to 192.168.2.10 and 192.168.2.11 respectively. Download the program to the PLC.

1. Use the M point button on the touch screen to control the corresponding Q point of the PLC, while monitoring the Q point output on the touch screen;

2. Input signal to the I point of the PLC to see if the touch screen detects the corresponding signal.

Colleagues in need hurry up to receive it~

Long press the left QR code to receive PLC learning materials

Disclaimer:This article is reproduced from the internet, and the copyright belongs to the original author. If there are any copyright issues, please contact us in time to delete it, thank you!

Complete question bank for the 2022 electrical engineer junior exam (including answers)

Three must-have tools for electrical engineers, just open with WeChat!

[Collection] The “path” of a ten-year-old electrician, the secret to earning over ten thousand a month!

The five major electrical drawing software (CAD, Eplan, CADe_simu…), which one do you pick?

The latest electrical version CAD drawing software, with a super detailed installation tutorial!

The latest electrical drawing software EPLAN, with a super detailed installation tutorial!

Common issues for beginners using S7-200 SMART programming software (with download link)

Comprehensive electrical calculation EXCEL sheets, automatically generated! No need to ask others for electrical calculations!

Bluetooth headphones, electrical/PLC introductory books are available for you to claim? Come and receive your electrical gifts!

Basic skills of PLC programming: Ladder diagrams and control circuits (with 1164 practical cases of Mitsubishi PLC)

Still can’t understand electrical diagrams? Basic electrical diagram reading, simulation software available, quickly get started with theory and practice!

12 free electrical engineer video courses, 10GB software/e-book materials, and 30 days of free live electrical courses are being given away!