Integration of PLC Smart Sensors: Real-Time Capture of Production Pulse, Reducing Failure Rate by 80%!

Last year, a food factory suffered a loss of 1.2 million due to a temperature sensor failure that caused 5,000 boxes of yogurt to spoil! Even more outrageous, an automotive factory incurred a penalty of 2.8 million due to a misalignment of a stamping machine caused by delayed vibration sensor data, resulting in a 3-day repair time! (Facepalm) These incidents share a common issue: the equipment status data cannot be fed back in real-time, rendering the PLC as “blind”.

1. Four-layer pyramid architecture, with second-level data response

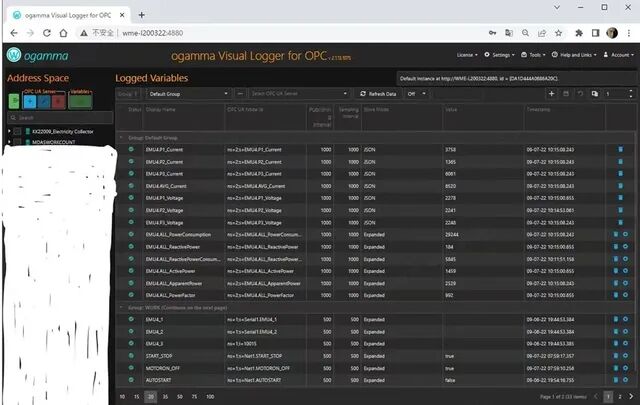

Perception Layer: Deploy multi-dimensional sensors (vibration, temperature, pressure) with an accuracy of 0.1% and a sampling frequency of 1000Hz.

Edge Layer: The Huachen Zhitong 5G gateway is equipped with an AI chip, completing data cleaning and anomaly detection within 10ms.

Protocol Layer: The Anybus gateway supports over 200 protocols, functioning like simultaneous interpretation at the United Nations, allowing seamless communication between Siemens and Mitsubishi devices.

Cloud Layer: The Hongke Cloud Platform generates real-time OEE reports with a fault warning accuracy of 98%.

2. Scene-specific solutions, targeted remedies

3. Pitfall Guide: These operations can bankrupt you in minutes!

5. Implementation roadmap: 4 steps to transform the production line

Assess the situation: Use Hongke tools to scan the equipment list and generate a “Digital Profile of the Production Line”.

Test the waters: Deploy Huachen Zhitong gateways on 3 production lines to validate the feasibility of the solution.

Roll it out: Complete the factory-wide transformation within 6 months while simultaneously training the technical team.

Go for it: Integrate with the MES system to achieve a closed loop of “data – decision – execution”.

6. Soul-searching question: Has your factory been hit?

Is the average handling time for equipment failures over 2 hours?

Is the sensor data delay over 1 second?

Are monthly losses due to data issues exceeding 100,000?

Real-time data flow makes the factory “smart”! When the PLC can understand the “heartbeat” of the sensors, and when equipment failures are nipped in the bud, you are just one step away from becoming an industry benchmark! (Raising arms in excitement) What are you waiting for? Equip your PLC with “listening ears” now, and let your competitors chase your tail lights!

——With 10 years of industrial experience, I will help you crush your peers with data!