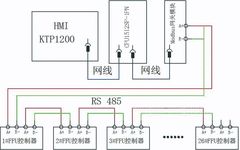

Siemens S7-1200 PLC and V20 Inverter Modbus RTU Communication Case Study

Introduction In actual work sites, PLCs are often used to control inverters. There are several ways for PLC to control inverters, such as terminal control, analog control, and communication control. Among these, communication control has certain advantages over the first two methods, such as the ability to read multiple data from the inverter with just … Read more