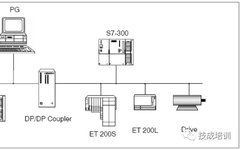

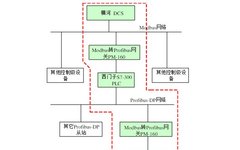

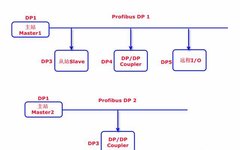

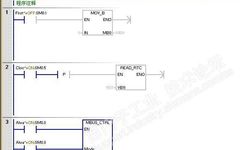

Siemens Communication Overview

Siemens Communication 1. Generally speaking, the communication network of an enterprise can be divided into three levels: enterprise level, workshop level, and site level. Enterprise Level: Top-level management of the enterprise; IT technology applications are very extensive, such as the INTERNET. Workshop Level: Solving communication between different process segments that need to coordinate work within … Read more