Alibaba has started to develop robots.

On September 17, at the Yunqi Conference, Alibaba’s “Little Donkey” was unveiled. It is Alibaba’s first logistics robot that can be mass-produced. Zhang Jianfeng, the head of Alibaba’s Damo Academy, introduced that the Little Donkey is “smart, capable, and safe.” At the same time, Alibaba launched its first robot platform, which will allow for rapid development of mobile robots for different scenarios, similar to building with Lego.

The combination of Alibaba and robotics seems unexpected. Previously, Alibaba had not publicly shown its ambition to fully enter the robotics field. Notably, the main entity behind the development of the “Little Donkey” robot is the Damo Academy’s autonomous driving laboratory.

As a company primarily focused on e-commerce, what is Alibaba’s intention in entering the robotics field with autonomous driving technology?

Little Donkey on the Road

With an animal name, the “Little Donkey” seems a bit more modest compared to the “Boston Dynamics Dog” that has excited the tech community with GIFs. This “donkey” from Alibaba cannot climb mountains, cannot pull trucks by hand, and cannot perform various tricks; it currently only does one thing—delivering packages. In fact, the Little Donkey looks more like an “unmanned vehicle” than a traditional “robot.”

However, the technology integrated into the Little Donkey is not far behind that of the Boston Dynamics Dog.

“The Little Donkey is still a robot; it just has four wheels instead of two legs, making it look like a vehicle,” Zhang Jianfeng emphasized in an interview. “Essentially, we have created a new platform that integrates with various industries, utilizing the best current autonomous driving technology and other technologies.”

Wang Gang, head of the Damo Academy’s autonomous driving laboratory, introduced that the Little Donkey has achieved cutting-edge L4 level autonomous driving technology and artificial intelligence technology. Although its speed is limited to 20 kilometers per hour, the mixed human-robot logistics scenarios in which the Little Donkey will be applied surpass the complexity of structured roads like highways.

As robots are set to hit the roads, safety inevitably becomes a concern. Wang Gang mentioned that the Little Donkey possesses human-like decision-making intelligence, capable of predicting the intentions of hundreds of pedestrians and vehicles within 0.01 seconds to avoid obstacles. In case of an emergency stop, the robot’s brain can make decisions, plan, and issue control commands within 0.1 seconds. In the past, similar demo products often froze in the middle of the road when faced with overly complex scenarios during road tests.

The Little Donkey’s environmental perception capability is so refined that it can recognize a 3-centimeter-wide connection line in the middle of the road and bricks no more than 5 centimeters high on the ground. These often-overlooked details are key breakthroughs that allow the product to transition from demo to commercial use. Additionally, the Little Donkey is equipped with multiple redundant safety systems, where the “little brain” can monitor passive safety aside from the “big brain,” and a remote driving system can allow a safety officer to take over the robot in extremely special circumstances. Overall, in 99.9999% of cases, the Little Donkey requires no human intervention.

Compared to the Boston Dynamics Dog, the Little Donkey has achieved a significant breakthrough: it truly possesses mass production capability.

“The Little Donkey will soon be mass-produced, achieving a shipment volume in the thousands; no other company in the world can achieve this scale,” said Chen Junbo, a senior algorithm expert at the Damo Academy’s autonomous driving laboratory, to Huxiu. The Little Donkey will soon appear in everyday scenarios.

Previously, the Little Donkey had been operating in closed campuses at Shanghai Jiao Tong University, Sichuan University, and Zhejiang University for nearly three years. The Little Donkey’s body uses the cabinet system of Cainiao Station, and after users schedule a delivery time, the Little Donkey will arrive downstairs within the scheduled time frame.

As communities are transformed or laid out for smart robots in the future, the Little Donkey will be able to take elevators and deliver packages directly to users.

Inevitable Risks

“There is a demand in society, there are needs in scenarios, and there is a technological accumulation,” Wang Gang summarized when explaining why they are making logistics robots.

In fact, for Alibaba, entering the robotics field through logistics scenarios and combining it with autonomous driving technology is almost a path determined by its genetic makeup.

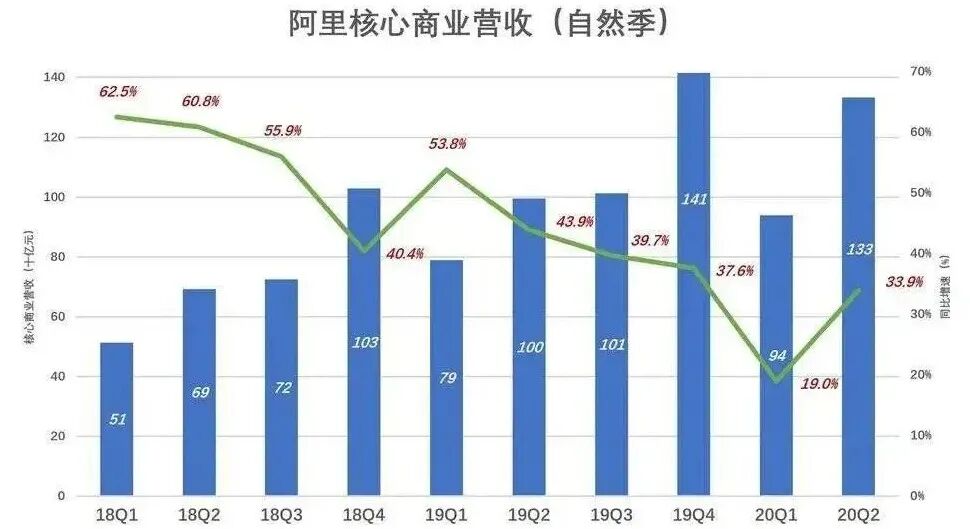

Alibaba’s Q2 fiscal report for 2021 shows that its core business remains the most important revenue pillar. High-tech business units represented by Alibaba Cloud have become the flywheel driving the second growth curve. Overall, the Alibaba economy generates an average of 450 million yuan daily from its core business “cash cow,” which continues to support other businesses.

From the perspective of revenue share, in recent years, the importance of core business to Alibaba has been increasing, and behind these sectors, there are invisible technological engines supporting and driving them, such as personalized recommendation algorithms for Taobao.

The core business, composed of e-commerce, wholesale, Cainiao, and local life, is a battlefield that Alibaba will never retreat from. All four of these businesses are inseparable from logistics delivery scenarios, and the last-mile logistics, which has low standardization and efficiency, has always been the most costly link.

In 2018, Alibaba established the autonomous driving laboratory, focusing on cutting-edge autonomous driving technology, led by Wang Gang, a scientist from Damo Academy with an algorithm background and a MIT TR35 talent. As a result, starting from basic technological capabilities, the Damo Academy’s autonomous driving laboratory first chose the most practical last-mile logistics scenario. One important project is to create truly mass-producible logistics robots. Stable performance and cost reduction are key to achieving mass production, but they are also global challenges.

It is reported that the significant reduction in the manufacturing cost of the Little Donkey mainly comes from technological innovations in three areas:

First, improvements were made to the perception system, including expensive sensors like LiDAR; for example, the self-developed perception algorithm of Damo Academy achieved high-beam simulation of low-beam LiDAR;

Second, a self-developed embedded computing platform was created, customizing high-performance, low-cost, and low-power computing units;

Third, hardware devices, including the motion chassis, were deeply customized to achieve high integration of software and hardware.

From the information conveyed externally, Alibaba’s planning for the robotics business is consistent with its clear strategy when heavily investing in high-tech businesses like cloud computing and AI:

First, support core business internally. Currently, Cainiao is the largest customer of the Little Donkey, and it can be imagined that Ele.me, Tmall Supermarket, Hema Fresh, and other local life businesses will likely deploy the Little Donkey in the future.

Second, create new businesses externally. Through an integrated hardware and software robot platform, Alibaba can quickly create other types of robots based on the general technologies and capability modules applied in the Little Donkey, such as those used for firefighting, epidemic prevention, airport services, scenic area guidance, and security patrols.

The Second Half of the Battle

In addition to being driven by internal business needs, external environmental trends have also forced Alibaba to accelerate its robotics development.

At the Yunqi Conference release site, Zhang Jianfeng predicted, “In the near future, China will generate 1 billion delivery orders daily.” Currently, the number of packages generated in China daily is about 200 million. The sharp increase in demand comes from the continuous growth of e-commerce business and the explosion of local life needs.

However, on the supply side, since 2012, the size of China’s working-age population has been declining for eight consecutive years, dropping below 900 million by 2018. The imbalance between labor supply and demand has become a key bottleneck hindering the development of manufacturing and service industries.

For a company like Alibaba, which relies on e-commerce and local life businesses, how to improve delivery efficiency by more than five times without a large-scale increase in manpower has become a pressing challenge. In the competition for the last mile, in addition to competing for talent, building robots has also become a necessary option.

Originally a company rooted in the internet, Alibaba did not understand manufacturing. However, in recent years, as technologies like computer vision, 5G, autonomous driving, and machine learning have matured, the robotics industry, previously dominated by traditional manufacturing companies like the four major families, has undergone a transformation. Tech newcomers with algorithm and talent advantages have found entry points; Google acquired nine robotics companies in one go in 2013, and Facebook began researching six-legged robots in 2018. However, in terms of willingness and capability, the companies most eager to drive change may be e-commerce giants like Amazon and Alibaba, which not only possess algorithms but also have essential scenarios.

In the automated logistics systems being deployed by Amazon and Alibaba, there are already hardware layers including wheeled robots, robotic arms, 3D cameras, cross-sorting belts, and AGVs, as well as software layers including perception algorithms, intelligent planning, decision-making brains, and control systems.

The robotics industry is undergoing a century-long transformation, entering the second half of the battle, where the Lego-style assembly of intelligent software and hardware capabilities may be the way for tech giants to disrupt the industry.

“Exchanging time for scale, and scale for technology.” In an interview, Wang Gang expressed excitement about the changes. In his view, achieving large-scale implementation ahead of the industry by one cycle is key for the Little Donkey to iterate at the fastest speed and further seize the technological high ground. Many people still question whether robots delivering packages is a pseudo-scenario. Wang Gang does not care; at least, the Little Donkey is about to hit the road in large numbers.

Special Planning