Femtosecond

This unit may be unfamiliar to many.

1 femtosecond

is one trillionth of a second.

Located in the High-tech Zone of Nanhu, Jiaxing,

Zhejiang Sais Electronic Technology Co., Ltd.

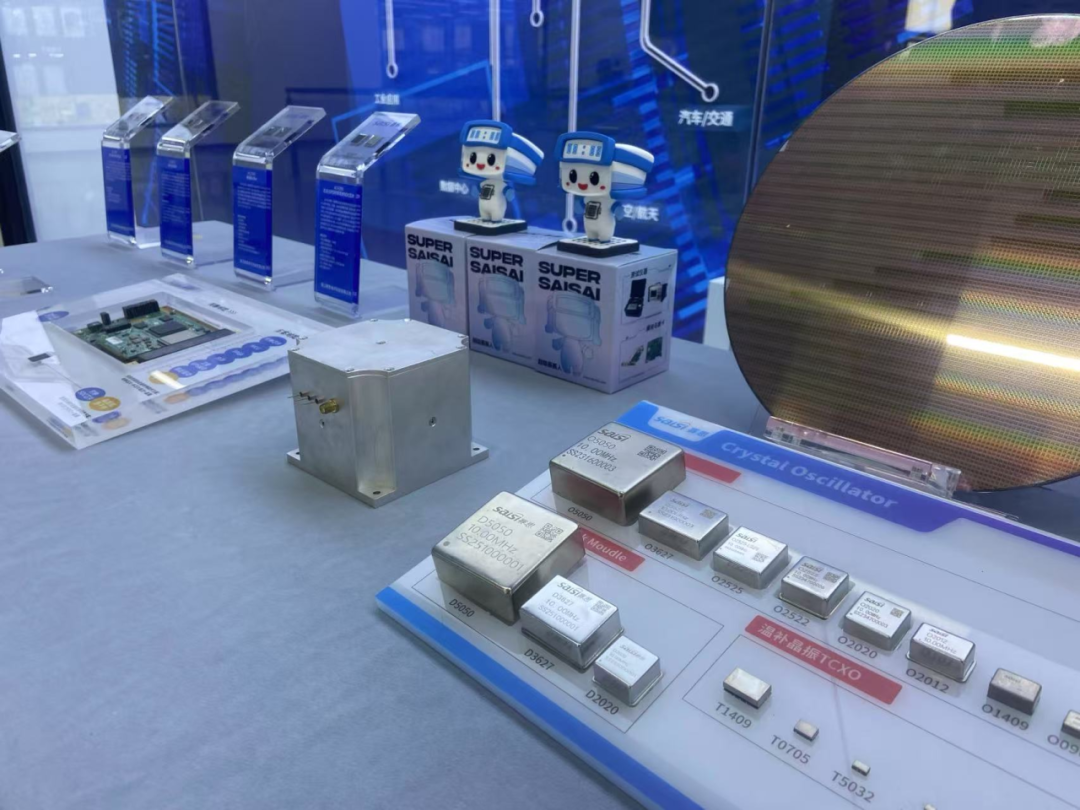

produces clock chips

that can control the jitter specification accuracy

to 100 femtoseconds.

On July 7, the testing workshop of Zhejiang Sais Electronic Technology Co., Ltd. in the High-tech Zone of Nanhu, Jiaxing, was bustling with activity. Engineer Liu Guoqing was intently focused on the programmer, his gaze sharp. In his world, there was only the rapidly moving code on the screen—strings of code symbols flashing and jumping, precisely being “inserted” into the chip that carries the precise “heartbeat”.

This unassuming domestic “heart” is supporting the safe high-speed operation of trains thousands of miles away and the precise positioning of satellites.

“Without clock chips, there is no ‘heartbeat’!” The company’s founder, Xu Wen, pointed at the experimental platform and raised his voice.Clock chips are the core of electronic systems in power, communication, and transportation; the operation scheduling of trains and subways relies on precise timing, and any slight deviation could lead to accidents.

However, the industrialization of time-frequency technology has long been monopolized by foreign countries. Xu Wen, a graduate of Zhejiang University, spent many years in the U.S. deeply engaged in the time-frequency field and served as a director at an industry giant. This experience left a deep impression on him: at that time, the domestic high-end clock chips were 100% reliant on imports.

In 2013, Xu Wen resolutely sold his property, raised 30 million yuan from various sources, and made a bold investment in the clock chip field, which was monopolized by the West, founding Sais Electronics in his hometown of Jiaxing. He understood that to surpass the competition, he had to take a different path, so he chose the digital-analog mixed chip track, focusing on signal processing and providing precise timing information.

Breaking through the “bottleneck” is no easy task!

In the winter of 2018, Xu Wen had just secured the first bulk procurement order from the three major telecom operators, but due to lack of experience, he put all his funds into component procurement. Suddenly hit by a financial storm, funding channels were frozen, and “the account was completely empty, and there was no salary for the next month.” At the brink of life and death,the state-owned assets of Nanhu District, Jiaxing City, the National Big Fund, and market-oriented funds timely injected 190 million yuan.

“This is not just a lifeline; it is also the country’s support for hard technology.”The lights in the laboratory have never gone out during the crisis.

Technical breakthroughs are also arduous.Building a maze of transistors on a silicon substrate the size of a fingernail, with a timing deviation tolerance not exceeding one trillionth of a second, is as difficult as “building a skyscraper on a strand of hair”.Xu Wen pointed to the lines under the electron microscope and explained: “High-voltage processes were once a major obstacle.” To meet the high-voltage requirements for long-distance signal transmission in foreign garage applications, the team conducted simulation tests for five years.

Experiments failed time and again, and materials were wasted batch after batch. Over five years, they went through dozens of tape-outs, investing over 400 million yuan but yielding no results, and even signs of hope were not visible.

“We were unwilling to give up!” The R&D team “crossed the river by feeling the stones,” dismantling chips for reverse learning while collaborating with wafer fabs to tackle process parameters.

A turning point occurred in 2023. Sais Electronics conquered key challenges such as miniaturization of time-frequency processing functions, clock jitter suppression, and high-precision time error detection,becoming the first domestic chip company to master this technology.

But problems followed one after another.

True localization must span the entire chain from design, tape-out, to packaging and testing. To completely break free from foreign architecture dependence, the team chose domestic cores but encountered excessive power consumption issues. “The foreign solution could be solved in three days, but we spent half a year optimizing it.” Xu Wen stroked the first batch of mass-produced chips, noting that every reduction of 1 milliwatt in power consumption was a breakthrough. Solving one bottleneck after another in research can only rely on technological accumulation and continuous practice. The R&D cycle for each chip at Sais Electronics is 1 to 2 years, but the initial accumulation requires 5 years, with countless experiments needed at every step, pursuing perfection.

After twelve years of honing, Sais Electronics has not only completed the localization of the entire industry chain from chip design to complete equipment but has also innovatively endowed the chips with reprogrammable design capabilities.Supporting all of this is the company’s annual investment of tens of millions in technological innovation, with R&D accounting for as much as 50%, and innovation centers spread across cities like Beijing, Xi’an, and Chengdu.

Today, Sais Electronics has become a leader in domestic time-frequency semiconductors, with products successfully applied in overseas markets such as the Mexico City Metro and African railways.Last year, the company achieved mass production of chips in the tens of millions, turning a profit for the first time, and is moving towards a hundred billion industry scale.

On the other end of the testing line, the performance testing of a dual-fiber dual-path time transfer system spanning thousands of kilometers has just been completed. This is part of Sais Electronics’ participation in a major national scientific and technological infrastructure project—the construction of a high-precision ground timing system. “This technology is currently world-leading, achieving time transfer at the picosecond level.” Xu Wen’s eyes sparkled with excitement.

At this moment

The wind farm in the Gobi Desert of Xinjiang

Sais Electronics chips

are providing nanosecond-level time synchronization for the power grid

The data center in Guangdong

is providing precise timing based on Beidou

The Mexico City Metro Line 1

is operating efficiently under the command of the Sais Electronics clock system

……

Each domestic “heartbeat”

is pulsating powerfully between the dimensions of time and space

Reading Recommendations

◇ The Nanhu High-tech Zone in Jiaxing has launched talent and innovation ecosystem construction

◇ Kudos! The Nanhu High-tech Zone in Jiaxing has won the “Best Integrated Circuit Park of the Year Award”!

Source: City News Media Center, Reporters Jiang Pengfei, Chen Xi, Zhou Lili, Ding Siyuan, Nanhu High-tech Zone (Jiaxing Science and Technology City)

Editor: Li Jisheng

Chief Editor: Qin Xiaoyun

Review: Lu Yun

Friendly Reminder:Due to WeChat’s changes in push rules, if you do not click “Looking”, you will gradually stop receiving our pushes. If you want to follow our authoritative information, please add“Nanhu Release”to yourstarred list, and don’t forget to click“Like”and “Looking”after reading.