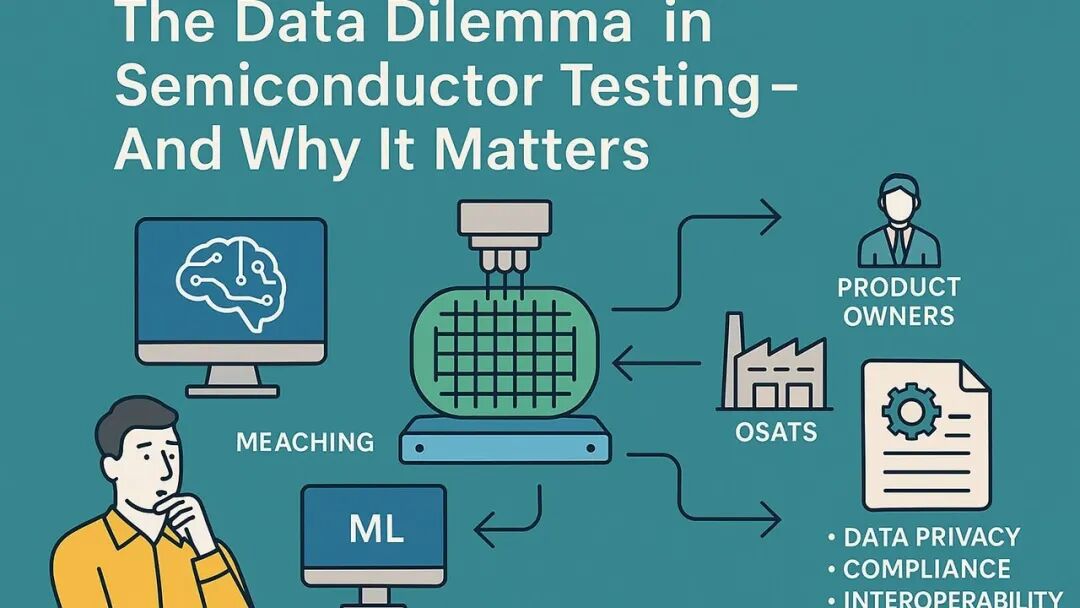

In today’s semiconductor industry, machine learning (ML) is no longer just a buzzword but a necessity for operations. From optimizing testing processes to identifying device drift, and executing VMIN or fine-tuning advanced analytics, ML-based applications are increasingly being used to improve yield, enhance quality, and reduce testing costs. However, there is a problem.

To make these intelligent applications work, engineers must access and share device testing data across multiple test insertion points, which often span different facilities and partners—such as fabs, OSATs (Outsourced Semiconductor Assembly and Test suppliers), and the product owners themselves. This concept, known as Data Feed Forward (DFF), is key to real-time test optimization. But how is DFF implemented in practice? That is the real challenge.

01

The Current State of Data Transmission in Semiconductor Manufacturing

Transmitting device testing data between enterprises is not as simple as sending a file. Transferring data between different companies has never been easy. These manufacturing environments place a high emphasis on security, requiring a secure platform to direct on-demand data to the intended recipients.

Then there is the data itself. Data preparation is a crucial task in the data analysis process. Before testing data can be used for downstream insertions, it must be organized, filtered, and formatted so that the next testing program can understand it. For companies attempting to build internal DFF infrastructure, this means significant investments in both personnel and tools.

In many cases, engineering teams are forced to spend more time handling data rather than conducting tests. This is a huge missed opportunity.

02

Why DFF is More Important Than Ever

Today, semiconductor testing platforms are expected to function more like real-time analytics engines. Each insertion can generate insights that improve the next insertion—provided that the data is available at the right time and place. Without robust DFF, you will not be able to:

- Make “on-site” adjustments to test conditions or limits based on cross-site/test operation grading/performance history

- Enhance the efficiency of trimming and search-directed testing

- Maximize final test yield and optimize testing operations to reduce testing costs

DFF data from different insertions can be used both within the testing program and externally. In some applications, customers may wish to run some compute-intensive AI/ML applications in parallel with the testing program. In such cases, they can use a dedicated edge server for running AI/ML inference with either a 1:1 configuration (one server per tester) or a 1:N configuration (N testers using one server).

Clearly, DFF is not just a technical feature. It is a key driver for achieving smarter and faster semiconductor testing.

In the following sections, we will delve into how ACS DFF simplifies data transmission, eliminates operational barriers, and enables high-impact machine learning during the testing insertion process without burdening your engineering team.

Scan the QR code to join the semiconductor industry communication group

Source: Public Information

Statement: Compiled by Flink Future Production Chain,for industry professionals only. Please cite the source when quoting, and contact: 18158256081 (same as WeChat) for reprints.