From Domain Architecture to Regional Architecture – Software Defined Vehicles (SWdV) and the Requirements for Future Data Lines

Currently, there are two terms that are unavoidable when reading automotive professional articles. One is the so-called “regional architecture”, which is often mentioned alongside “Software Defined Vehicles (SWdV)”.

What do these terms mean? How will they impact future generations of vehicles? These are the questions we will explore in this blog post.

-

1 Review of the Past: Complex Wiring and Heavy Weight

-

2 Current Technology Status: Domain Architecture:

-

3 Future Automotive Electrical Systems: Regional Architecture and Software Defined Vehicles:

-

4 Outlook: Huge Demand for Computing Power and Data Lines

-

5 Summary:

-

6 Conclusion:

1

Review of the Past: Complex Wiring and Heavy Weight

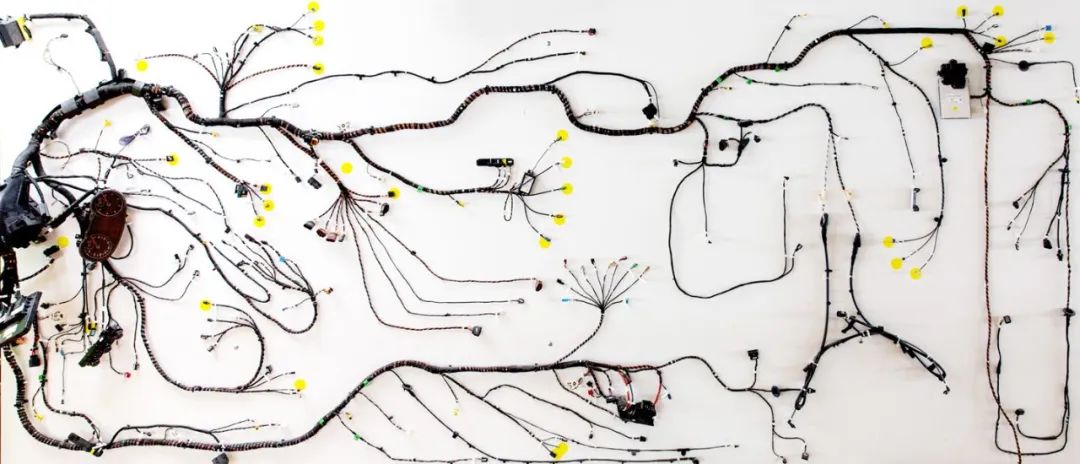

What do the terms “regional architecture” and “Software Defined Vehicles (SWdV)” mean? How will they impact future generations of vehicles? To answer these questions, let’s briefly review the past. The first form of automotive electrical system topology is known as “distributed” or “modular architecture”. In this form, all sensors and actuators are individually connected directly to a control unit. Each sensor or actuator has the intelligence required for its function and only transmits control signals and prepared measurement signals via cables and bus systems (usually Lin or Can bus) to the control unit. Each vehicle is equipped with hundreds of sensors and up to a hundred control units. The length of individual cables can reach up to 16.5 meters. This often results in the total length of wiring inside the vehicle quickly exceeding a kilometer. The result is extremely complex wiring and a significant weight of the wire harness.

Modular Architecture

Each control unit must be programmed with software (firmware) specifically designed for its function. Firmware updates typically can only be performed directly on the device using special programming cables. This requires going to a specialized repair shop, and updates occur only in rare cases.

Extending vehicle functions with additional features after leaving the factory is very difficult, if not impossible. Each function requires at least one additional cable connected to the control unit installed in the vehicle. Firmware on the control unit typically needs to be updated to support the new function. The costs in such cases quickly exceed the benefits obtained.

As the number of vehicle functions increases, especially in safety and comfort areas, this wiring form quickly reaches its limits.

This marks the birth of “domain architecture”.

2

Current Technology Status: Domain Architecture:

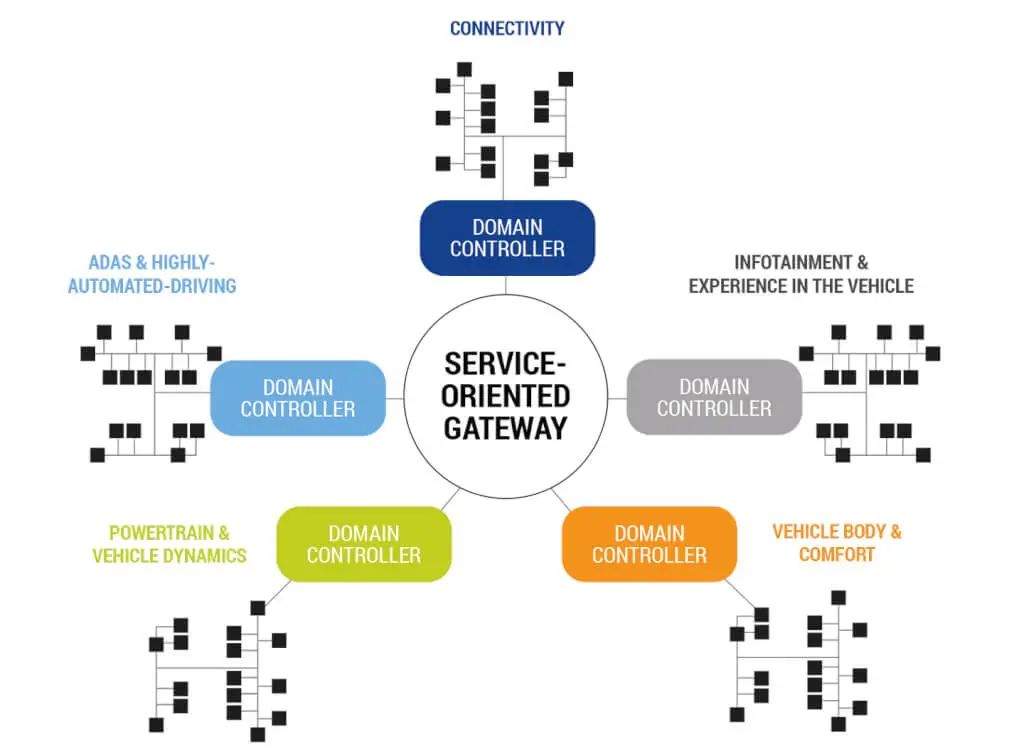

Unlike “modular architecture”, the approach of domain architecture is to classify sensors and actuators based on their functions and tasks (domains). Various functional domains are defined in the vehicle, such as drive, comfort, or infotainment. Each of these is monitored and controlled by a higher-level control unit, the Domain Control Unit (DCU). The connection to sensors/actuators can be achieved through low-cost bus connections (e.g., Lin or Can bus). The control unit itself is connected to a powerful, service-oriented network, known as a gateway (e.g., Ethernet). Thus, new functions like ADAS (Advanced Driver Assist System) can be easily integrated into additional domains or control units at any time.

Domain Architecture

However, if a domain’s functions cannot be physically installed in the same location in the vehicle, the drawbacks of this technology quickly become apparent. This leads to excessively long cables from the control unit to the sensor or actuator. For instance, consider the simple example of the “turn signal” function: at least six turn signals should be wired in different corners of the vehicle, but all turn signals are triggered by one control unit. This type of vehicle topology reflects the current technological status!

However, the automotive world is currently undergoing an extreme transformation. In addition to replacing internal combustion engines with alternative drives, the major trend of “autonomous driving” is permeating the entire industry, necessitating new designs for future automotive electrical systems.

3

Future Automotive Electrical Systems: Regional Architecture and Software Defined Vehicles:

Domain architecture certainly has some advantages. However, to cope with the complexity of modern vehicles and meet future requirements, a different approach is needed: regional architecture.

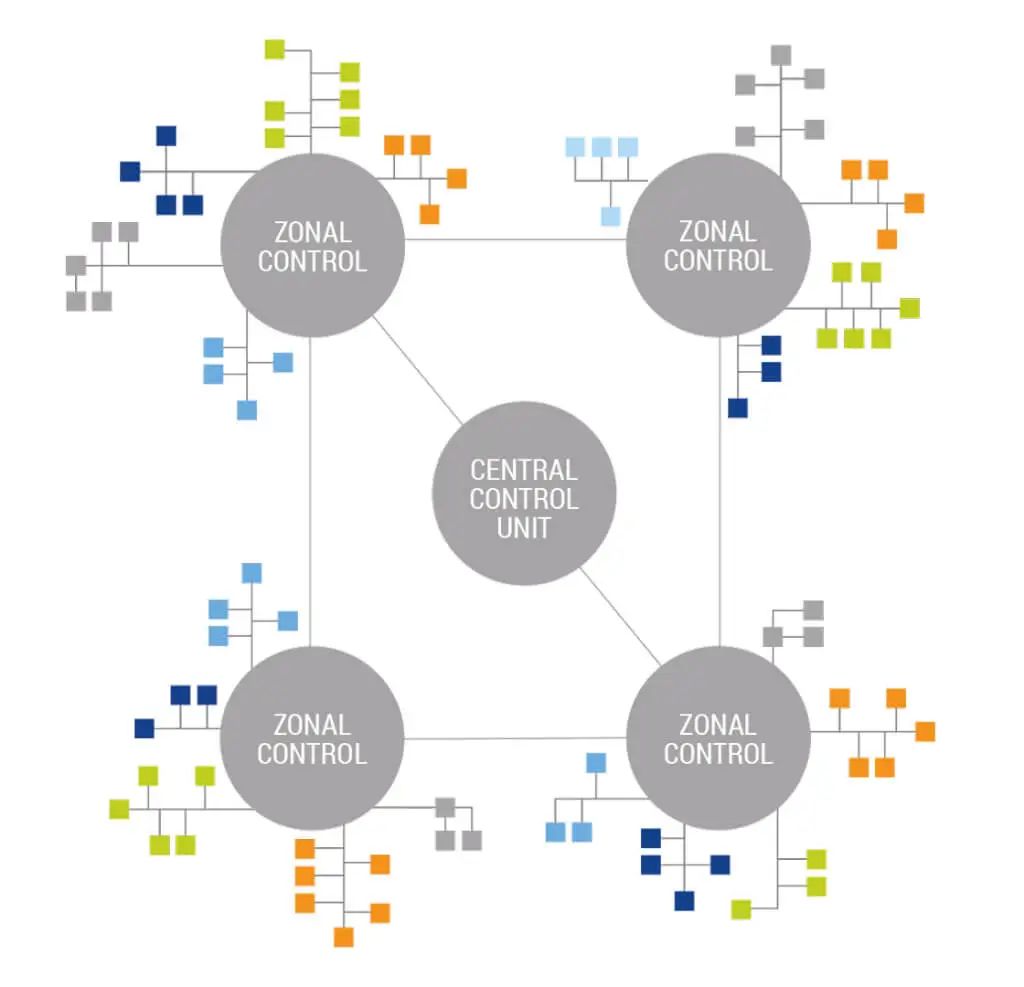

The regional approach (regional architecture) organizes functions based on their location in the vehicle rather than according to their tasks. A simple vehicle may have only four regions, one in each corner. All devices in a physical region are controlled by a regional controller, also known as a regional gateway or control unit (Electronic Control Unit). These regional controllers are connected to a central computing unit via a backbone link (high-speed data link).

All tasks monitored by the regional control unit in a physical region are assigned to that region. Thus, lighting, image sensors, turn signals, brakes, steering, suspension, etc., can be grouped into a common area.

Regional Architecture

In addition to simplifying wiring, modularity and flexibility play a very important role in fully realizing the advantages of this solution.

Here, modularity means that different tasks can be implemented using the same hardware (e.g., the same control unit).

Flexibility refers to the ability to update, fix errors, configure, and expand without imposing excessive costs on the driver. With the so-called “Over the Air” (OTA) capabilities, these operations can be performed via an internet connection without having to go to the repair shop. The vehicle checks for updates and independently loads or updates the software on its control unit. Options and expansions can be purchased and installed by the owner, similar in principle to the app stores offered by well-known mobile device operating system providers.

To implement this modularity and flexibility in practice, it will be necessary to generate these functions in software rather than through hardware in the future. The model of modern smartphones is a great example in this regard, where users can access a wide variety of tasks and applications through apps. In addition to making calls, smartphones can take photos or navigate. If desired, banking transactions or information from social media can also be completed.

This approach in vehicles is referred to as “Software Defined Vehicles”. Almost all functions in the vehicle are no longer realized through hardware-based controllers but are handled by programs (Apps) on a general control computer (regional controller). The advantage is that many applications can run simultaneously (multitasking), allowing all functions of one region to be implemented on one regional controller. Of course, this requires very high computing power, but also requires a large number of interfaces installed in the regional controller that connect to sensors/actuators. The tasks of these regional controllers also include communication with the central computing unit. The data sent to that center is therefore pre-filtered and prioritized by the regional controller. This significantly reduces system complexity, allowing the central computing unit to focus on processing important data (e.g., ADAS functions, evaluating image data, etc.).

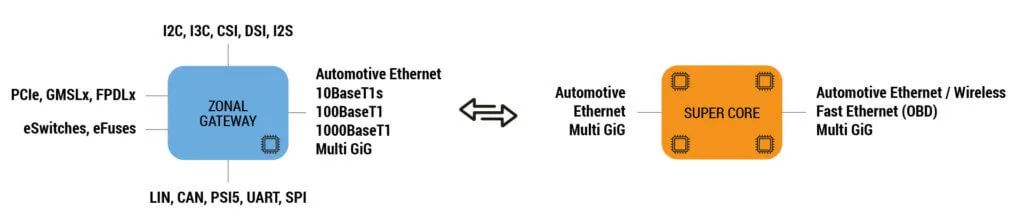

The data connection between the regional controller and the central computing unit needs to be reliable and fast. Automotive Ethernet solutions (e.g., MultiGiG) are the means to achieve this.

This connection is known as the backbone.

Communication from the Regional Gateway to the Central Computer

The approach of “Software Defined Vehicles” inevitably leads to a significant paradigm shift for manufacturers. While vehicle manufacturers have so far been the proprietary technology carriers of the hardware installed in vehicles, these functions and value creation are now almost entirely shifting from hardware to software. The focus is no longer on the vehicle itself, but rather on the functions, which can be personalized according to customer requirements. However, so far, software development is not a core competency of manufacturers. Therefore, we can already see different trends in this area. Some companies (usually younger ones) tend to move towards software service providers or complete systems (e.g., Android from Google), while “traditional” manufacturers are more inclined to try to retain proprietary technology in-house and invest in building their own software departments. Regardless of which route prevails in the long term, it is exciting.

Equally interesting is the emergence of entirely new business models.

Functions are no longer tied to the vehicle itself. Second-hand car dealers, or even customers, can relatively easily retrofit new functions, thereby creating added value for the vehicle. As a result, the value of the car remains constant throughout its product lifecycle, or may even increase.

Now, temporary use of functions or subscription solutions can also be offered.

Another advantage is that vehicles can communicate with their surrounding environment. Data can be collected during the vehicle’s operation and stored in, for example, the cloud. Through this data exchange, functions and services can be continuously improved, which can then be updated in real-time in the vehicle. Direct communication between multiple vehicles is also technically conceivable. All these possibilities represent another important milestone on the road to autonomous driving.

4

Outlook: Huge Demand for Computing Power and Data Lines

Converting the automotive electrical system architecture to regional architecture will, of course, take some time. The challenges such as the required 25 Gbit/s or higher computing power and data lines still need to be addressed. However, it is estimated that this could be achieved by around 2030. Technicians around the world are working hard to find solutions.

MD ELEKTRONIK, with its product portfolio, has become a very strong and competent partner focusing on these requirements. We provide appropriate solutions for coaxial cables, UTP and STP (*), as well as USB products, and optical data transmission. Thanks to a highly automated production strategy, our products meet the highest quality standards.

5

Summary:

The automotive world is undergoing tremendous changes. The transition to electric drives not only poses significant challenges for car manufacturers, but also providing solutions for the idea of a “four-wheeled smartphone” is equally important.

One important approach in this regard is to replace numerous individual “point-to-point” cables with low-cost network cables (e.g., MultiGiG Ethernet) to improve the efficiency of automotive electrical systems. This not only brings significant weight reduction benefits but also poses a huge challenge for control unit manufacturers, as many functions previously implemented in single sensors or actuators are now integrated into these control units as software solutions. These two approaches are described as “regional architecture” and “Software Defined Vehicles”.

6

Conclusion:

The demands for computing power and data transmission are extremely high, and there is still much room for improvement. Future data lines must be designed to enable reliable data transmission at rates of no more than 25 Gbit/s or faster. Optical data lines are increasingly becoming an excellent alternative to copper-based cables in this regard. (Author: Christoph Z, Meind)

Welcome to all angel round enterprises in the automotive industry chain (including the dynamic battery industry chain)Around enterprises to join the group (to be recommended to 800 automotive investment institutions including top institutions at home);There are communication groups led by science and technology innovation companies, dozens of groups in the automotive industry including complete vehicles, automotive semiconductors, key parts, new energy vehicles, intelligent connected vehicles, aftermarket, automotive investment, autonomous driving, Internet of Vehicles, etc. To join the group, please scan the admin’s WeChat (Please indicate your company name)