A team from Huazhong University of Science and Technology published a paper titled Structural homogenization of 3D-printed metallic glass by cryogenic thermal cycling in the international journal Journal of Alloys and Compounds.

01

Paper Overview

At the intersection of materials science and advanced manufacturing technology, laser 3D printing technology offers unprecedented opportunities for the preparation of high-performance materials with complex shapes due to its exceptional manufacturing flexibility and precision. Metallic glasses (MGs), as amorphous alloy materials with excellent mechanical properties and unique physical characteristics, have become a key area of focus for 3D printing technology due to their outstanding performance in high strength, high hardness, and excellent corrosion resistance. However, the 3D printing process inevitably introduces structural inhomogeneities, such as local residual stresses, porosity defects, and localized crystallization in the heat-affected zone, which severely restrict the fatigue performance and long-term service reliability of metallic glasses, becoming a “bottleneck” that hinders their advancement into high-end applications. To overcome this technical bottleneck, cryogenic thermal cycling (CTC) has emerged as a highly promising post-processing method. The CTC technology introduces thermally induced structural rearrangement and energy control mechanisms within the metallic glass by precisely regulating periodic temperature changes, thereby achieving significant improvements in material performance. This process not only effectively alleviates residual stresses but also optimizes the structural uniformity of metallic glasses on a microscopic scale, bringing new hope for the performance optimization of metallic glasses.

Laser & Electron Beam Processing

02

Full Overview

In this paper, the authors investigate the effects of cryogenic thermal cycling (CTC) treatment on Zr47.5Cu45.5Al5Co2 MG prepared by laser powder bed fusion technology. The results indicate that CTC treatment preserves the amorphous structure while increasing the relaxation enthalpy and decreasing hardness, demonstrating an effective recovery process. After 50 cycles of CTC treatment, the compressive strength and plasticity of the MG significantly improved, and the structural homogeneity and repeatability were also enhanced, as verified by Weibull statistics. Furthermore, the MG after CTC treatment exhibited a longer fatigue life in cyclic compression tests, indicating higher reliability under repeated loading. These results highlight the potential of CTC as a post-processing method for 3D-printed MGs to enhance their robustness and durability.

Laser & Electron Beam Process

03

Graphical Analysis

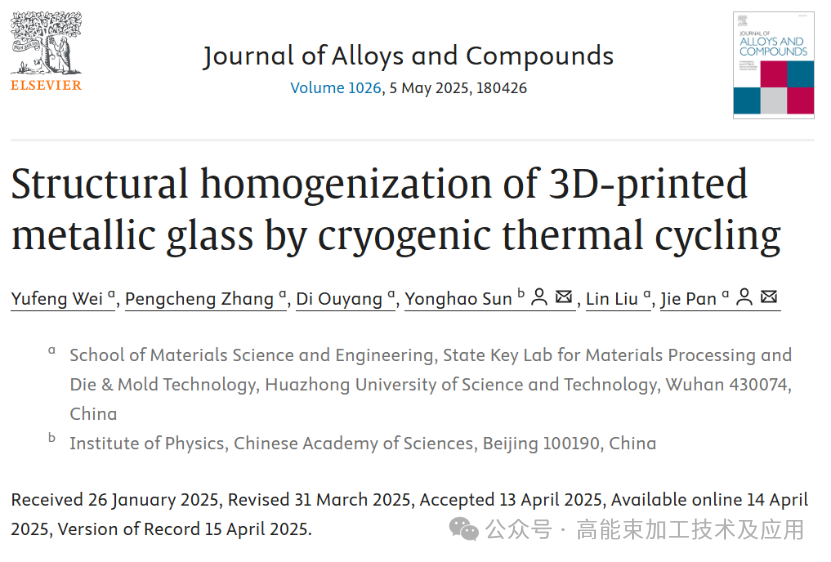

Figure 1 shows the analysis results from XRD, high-resolution TEM, and SAED, clearly indicating that the 3D-printed Zr47.5Cu45.5Al5Co2 amorphous alloy maintains good amorphous characteristics before and after CTC treatment, with no significant changes in atomic structure due to CTC treatment, which is crucial for studying the performance of this material under different processing conditions and exploring its potential applications.

Figure 1. Structural analysis of the original and cryogenically cycled Zr47.5Cu45.5Al5Co2 MG samples. (a) X-ray diffraction; (b) TEM image of the original printed sample; (c) TEM image of the 50 CTC sample. The inset shows the electron diffraction pattern of the selected area.

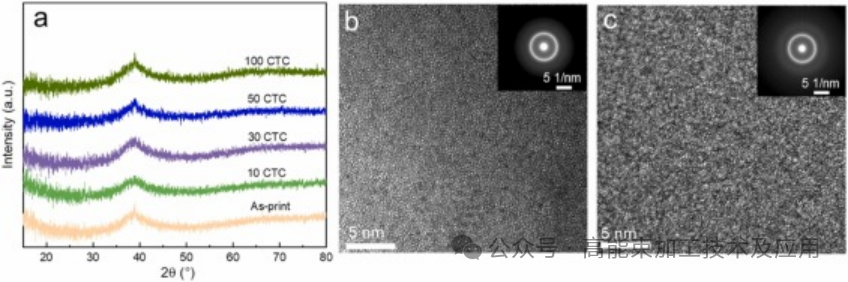

Figure 2 shows the DSC curves indicating that CTC treatment significantly affects the thermal behavior of 3D-printed metallic glass. All samples exhibited pre-exothermic events before the glass transition temperature (Tg), related to structural relaxation. The structural relaxation enthalpy (ΔHrel) increased with the number of CTC cycles, reaching a maximum of 9.2 J/g after 50 CTC cycles, approximately 1.6 times that of the untreated sample. After 100 CTC cycles, ΔHrel slightly decreased to 8.5 J/g but remained higher than that of the untreated sample. This indicates that CTC treatment homogenizes the structure of metallic glass, saturating internal energy, with structural relaxation dominating, ultimately forming a dynamic equilibrium. The increase in ΔHrel is closely related to the free volume content, structural disorder, and residual stress of the metallic glass, indicating a rejuvenation of the structure. Therefore, CTC treatment revitalizes 3D-printed metallic glass, with the best effect observed after 50 CTC cycles.

Figure 2. (a) DSC curves of 3D-printed MG during 0-100 CTC; (b) Relationship between relaxation heat ΔHrel and the number of cycles.

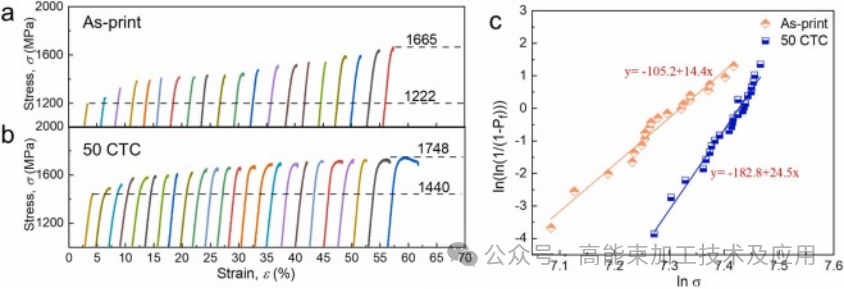

Figures 3(a) and (b) show the engineering stress-strain curves of the printed and 50 CTC-treated metallic glass samples. The compressive strength of the printed samples ranged widely (1222-1665 MPa), with an average strength of 1459 MPa, and most exhibited brittle fracture. In contrast, after 50 CTC treatment, the strength of the samples became more stable (1400-1748 MPa), with the average strength rising to 1644 MPa, and plasticity significantly improved, with maximum plasticity increasing from 0.6% to 3.3%.

Figure 3. (a) Compressive stress-strain (σ-ε) curves of printed samples and (b) 50 CTC samples, with the strain axis offset for clarity. (c) Weibull plot of 3D-printed MG under compression.

04

Conclusion

Cryogenic thermal cycling is applied to 3D-printed Zr-based metallic glass. The results indicate that the number of compressive fatigue cycles increased by 1-5 times, and the compressive strength improved by 13%. Weibull statistics show that the samples exhibited higher structural uniformity and repeatability after CTC treatment. The relaxation enthalpy of the 3D-printed metallic glass increased after CTC treatment, primarily due to the expansion of low-temperature exothermic events reflecting residual stress. Microhardness results indicate that the 3D-printed metallic glass softened after low-temperature treatment. Regardless of the structural diversity present in the printed metallic glass, the reduction in nano-hardness after low-temperature treatment (especially in the heat-affected zone) led to a uniform linear distribution of nano-hardness. The results highlight the prominent phenomenon of structural homogenization in terms of free volume concentration and residual stress distribution at the nano and micro scales. Cryogenic thermal cycling is a feasible method for post-processing 3D-printed metallic glass.

Laser & Electron Beam Processing

Original Link:

https://doi.org/10.1016/j.jallcom.2025.180426

Previous Recommendations

1、Introduction to Laser Mass Transfer Technology for Micro LEDs

2、Introduction to Laser Cutting Technology for Silicon Carbide

3、Application of Ultrafast Lasers in Aircraft Engines

4、Application of Physics-Informed Machine Learning in Additive Manufacturing

5、Optimization of Additive Manufacturing Process Parameters Using Machine Learning and Optimization Algorithms

6、Femtosecond Laser-Induced Artificial “Chicken Skin” Driven Micro-Actuator Structures

7、Hydrodynamic Simulation of Laser-MIG Hybrid Welding of 316 LN Stainless Steel

8、Application of Laser Additive Manufacturing in Biomimetic Metal Structures

9、Near-Infrared Femtosecond Laser Direct Writing of Microchannels and Controllable Surface Wettability

10、Effects of Energy-Adjustable Ring-Shaped Laser on Intermetallic Compound Formation and Mechanical Properties of Steel-Aluminum Laser Welding Overlap Joints

Call for Papers

Long-term call for papers, everyone is welcome to submit

Reprint & Submission Channel:Emaill[email protected]

Please title the submission email as “Submission + Article Title” and attach the article as a file.