In embedded system design, selecting an ADC chip requires a comprehensive consideration of performance, application scenarios, and development costs. The STM32’s ADC and dedicated ADC chips like the AD7606 exhibit significant differences in core parameters, functional features, and applicable scenarios. Below is a comparative analysis and selection advice for both:

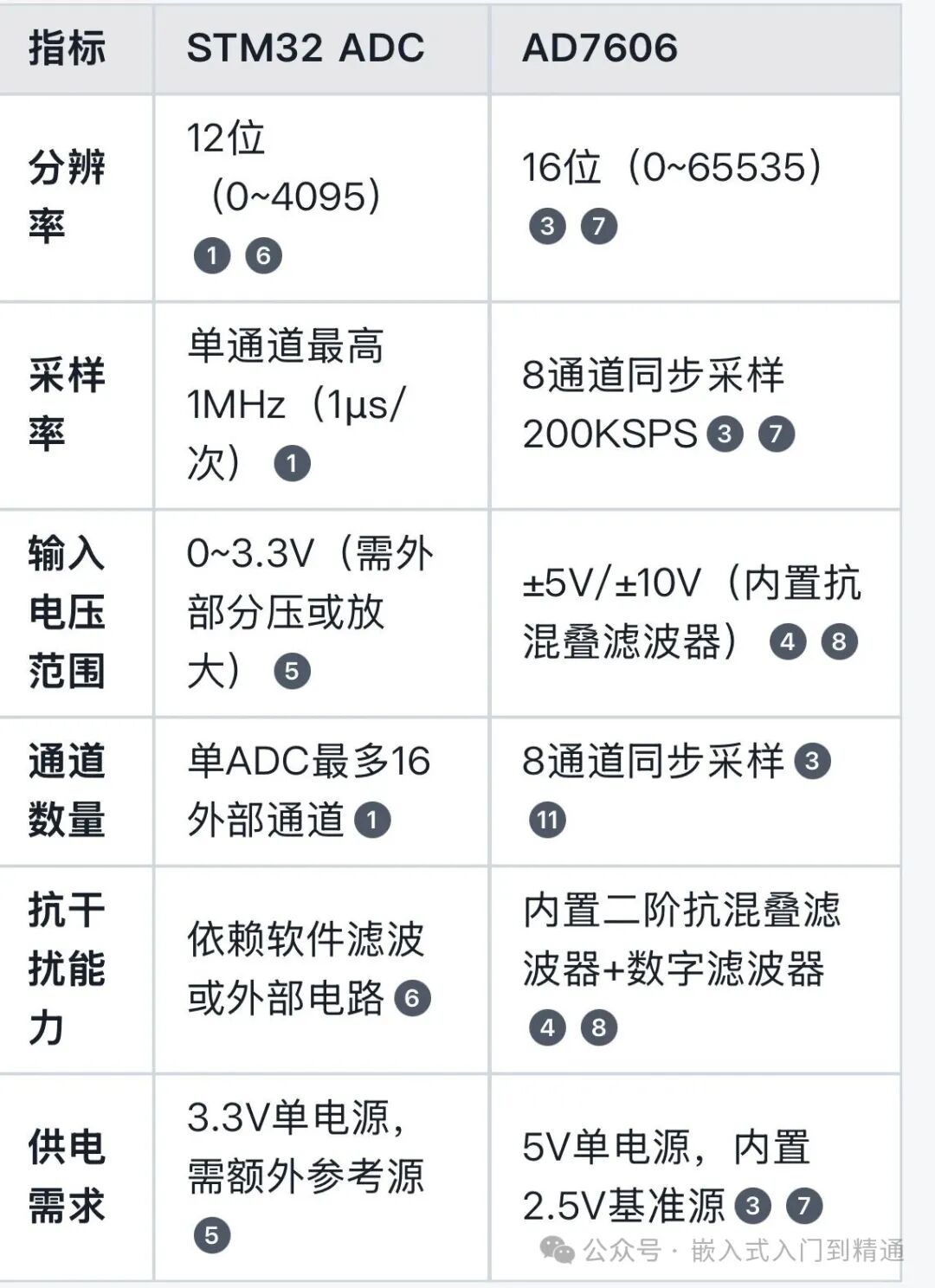

1. Performance Parameter Comparison

2. Core Functional Differences

2.1 Multi-channel Synchronous Sampling Capability

2.1.1 STM32 ADC:

Utilizes a time-division multiplexing mode, where the regular group and injected group must switch channels over time. The conversion order is configured by registers, leading to channel switching delays and timing errors. For example, a 16-channel scan requires sequential triggering, which cannot guarantee strict synchronization.

2.1.2 AD7606:

Offers 8-channel fully synchronous sampling, with all channels starting at the same sampling moment, suitable for scenarios such as three-phase voltage/current synchronous acquisition in power systems and multi-sensor data fusion, with timing errors <1μs.

2.2 High Precision and Anti-Interference Design

2.2.1 STM32 ADC:

At 12-bit resolution, the signal-to-noise ratio (SNR) is approximately 60dB, relying on external filtering circuits and software calibration (e.g., analog watchdog threshold detection).

2.2.2 AD7606:

Achieves an SNR of 95.5dB at 16-bit resolution, with a built-in second-order anti-aliasing filter (cutoff frequency 15~23kHz) and digital filter (programmable oversampling rate), enhancing noise suppression capability by over 50%.

2.3 Input Range and Electrical Characteristics

2.3.1 STM32 ADC:

Input voltage is strictly limited to 0~3.3V, requiring external operational amplifiers or voltage divider circuits to handle industrial-grade signals (e.g., ±10V sensors), increasing hardware complexity.

2.3.2 AD7606:

Directly supports ±10V input, with an input impedance of 1MΩ and built-in ±16.5V clamping protection, allowing direct connection of industrial sensors and simplifying circuit design.

2.4 Interface and Integration

2.4.1 STM32 ADC:

Relies on DMA transfer and software triggering, requiring time-division processing of multi-channel data, which consumes high CPU resources. For example, continuous scanning of 16 channels requires configuring SQR1~SQR3 registers, resulting in higher code complexity.

2.4.2 AD7606:

Integrates parallel/serial dual interfaces, supporting bus mode (8-bit/16-bit) and SPI mode, with a data read rate of up to 200KSPS, allowing direct interfacing with FPGA or high-speed MCUs, reducing intermediate processing steps.

3. Typical Application Scenario Analysis

3.1 STM32 ADC Applicable Scenarios

Low-power small devices: such as smart home sensors (temperature and humidity, light), single-channel requirements, cost-sensitive projects.

Simple signal monitoring: battery voltage detection (0~3.3V range), low-frequency signal (<1kHz) acquisition, without the need for high precision.

3.2 AD7606 Applicable Scenarios

3.2.1 Industrial Automation:

Synchronous acquisition of three-phase voltage/current in power systems (requiring ±10V input and multi-channel synchronization), motor control feedback signal processing.

3.2.2 Medical Devices:

ECG/EEG signal acquisition (16-bit precision + digital filtering to suppress electromyographic interference), endoscopic pressure monitoring.

3.2.3 High-Speed Data Acquisition:

Automotive ADAS radar signal processing (200KSPS sampling rate), audio codec (SNR >90dB).

4. Selection Recommendations

4.1 Situations Not Recommended for STM32 ADC

4.1.1 High Precision Requirements:

For medical-grade devices requiring 16-bit resolution (STM32 ADC error ±1LSB, AD7606 error ±0.5LSB).

4.1.2 Multi-channel Synchronization:

Power harmonic analysis requiring 8-channel strict synchronization (STM32 time-division error can reach microsecond level).

4.1.3 Wide Input Range:

Industrial sensor signals of ±5V or ±10V (STM32 requires additional circuit processing).

4.2 Preferred Scenarios for AD7606

4.2.1 Industrial Control:

Requires multi-channel synchronization, strong anti-interference, and high integration.

4.2.2 Medical Electronics:

High precision, low noise, high-speed sampling.

4.2.3 High-Speed Data Acquisition:

Such as vibration analysis and audio processing.

5. Development Cost Comparison

6. Conclusion

6.1 STM32 ADC: Suitable for low-cost, low-complexity small projects, such as consumer electronics and simple sensor monitoring.

6.2 AD7606: Significantly outperforms STM32 ADC in scenarios requiring multi-channel synchronization, high precision, and wide input range, making it the preferred choice for industrial automation, medical devices, and high-speed data acquisition.

Selection Principle:

If project requirements involve 16-bit precision, ±10V input, and multi-channel synchronous sampling, it is recommended to directly use dedicated ADC chips like the AD7606; if only basic signal acquisition (such as battery monitoring or temperature detection) is needed, the STM32 ADC still offers a cost-effective advantage.