The technology for removing CO2 from the air, known as Direct Air Carbon Capture (DAC)[22], differs from CCUS technology, which targets carbon capture from industrial fixed source emissions. DAC can capture CO2 emissions from distributed sources such as small fossil fuel combustion devices and vehicles. This technology generally employs physical and chemical adsorption methods, but the concentration of CO2 in the atmosphere is only 0.042%, making the energy consumption for capturing and concentrating CO2 using DAC technology relatively high. The key to this technology lies in developing efficient and low-cost adsorbent materials, including both liquid and solid adsorbents, with solid adsorbents exhibiting better kinetic performance, effectively avoiding solvent loss and reducing thermal consumption, thus having broader applications[23]. In recent years, electric oscillation adsorbents[24], metal-organic framework materials (MOFs)[25], and porous hydrogen-bonded organic frameworks (HOFs)[26] have become research hotspots. Among them, the chemical building blocks, pore size and shape, and order of MOFs can be adjusted, with a specific surface area of up to 6600 m2/g, which has been widely studied for CO2 capture and conversion[27]. Currently, domestically, a MOFs material HKUST-1 with good water resistance has been prepared in the laboratory, with an adsorption capacity of 2.5 mmol/g at 308K and 100kPa, outperforming existing adsorbents, and it is expected that a MOFs with an adsorption capacity of 7 mmol/g can be prepared soon.

In terms of cost, the production cost of HOFs is too high and has not yet achieved industrialization, while MOFs materials are more cost-effective. Sinha et al.[28] developed two MOFs for DAC technology, MIL-101(Cr)-PEI-800 and mmen-Mg2(dobpdc), with estimated minimum energy consumption and costs of 3.3 GJ/tCO2 (915 kW·h/tCO2) and 540~1008 yuan/tCO2, as well as 2.6 GJ/tCO2 (713 kW·h/tCO2) and 432~1368 yuan/tCO2, with the international advanced level being 2.2 GJ/tCO2 (611 kW·h/tCO2). The Australian company Airthena has developed a mobile DAC pilot device based on MOF materials, with MOFs polymer nanocomposites as adsorbents coated on the surface of heating plates, with a coating thickness of 30~200 mm, composed of at least 50 wt% MOF and adhesive. The regeneration energy consumption is 1600 kW·h/tCO2, and the obtained CO2 product concentration is about 80%, with an operating cost of 252~2520 yuan/tCO2[29].

The University of Calgary in Canada has developed a CALF-20 that has a high adsorption capacity and selectivity for CO2 with a low enthalpy regeneration value, which exhibits outstanding durability and stability (>450,000 cycles) even in steam, wet acidic gases, and prolonged exposure to direct flue gas from natural gas combustion. In terms of synthesis cost, most MOFs require non-protic solvents (such as dimethylformamide or diethylformamide) or contain expensive organic binders. In contrast, CALF-20 uses water and methanol as solvents, with a synthesis cost of about 92,000 yuan/t, and the cost per cycle for 450,000 cycles is 0.2 yuan/t. This achievement has been patented to Canadian Svante Inc., which, in collaboration with BASF, has begun large-scale production of CALF-20, achieving a space-time yield of 550 kg/(m3·d). The author’s team is developing MOFs for industrialization, including HKUST-1, Mg-MOF-74, and ZIF-8, aiming to control the material cost at 50,000~100,000 yuan/t, with cycle counts exceeding 10,000.

Source: Clean Energy CCUS

Download the app to watch the live replay

Download the app to watch the live replay

Use your mobile browser to scan the QR code on the left

Select “Android version” or “iOS version”

Follow the page guide to download and install the “International Petrochemical Online” App

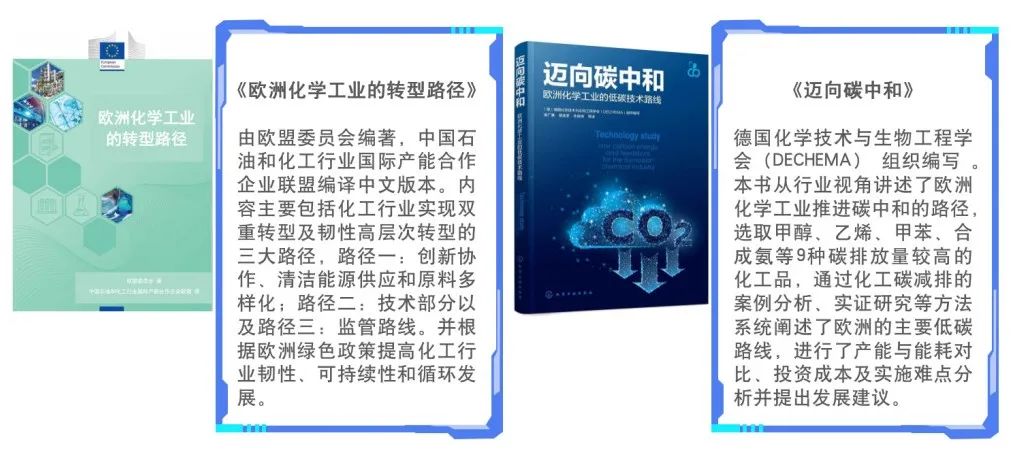

Recommended good books, pre-order quickly

Recommended good books, pre-order quickly

Disclaimer: This article only represents the author’s personal views and is not related to the Petrochemical Industry Going Global Alliance. The originality and the statements and content in the article have not been verified by the alliance, and the Petrochemical Industry Going Global Alliance does not guarantee or promise the authenticity, completeness, or timeliness of this article and all or part of its content. Readers should only use it as a reference and verify the relevant content themselves.

Click here to let Huaxiaomeng know you are “watching”~👇